It is known that large weights can be easily lifted using a jack. Jacks are used not only for cars. It can also be useful on the farm. But what to do when such a device breaks down or does not exist at all? There is an exit. You can quickly make a jack with your own hands. All you need is a welding machine, a small amount of metal and some parts that can be found around the house. In this article we will describe the process of making a homemade jack.

Will need

- metal pipe 200 mm long (diameter 50-60 mm);

- metal plate 5 mm thick (size 300x70 mm);

- corner 250 mm long – 2 pcs;

- metal tube with a diameter of 20 mm (length about 150 mm) – 2 pcs;

- metal square tube 20x20 mm (about 200 mm) – 2 pcs;

- a rod with a thread for a nut (approximately 20 mm thick);

- nut for the rod – 2 pcs;

- a thick-walled piece of round metal (diameter about 3.5-4 mm);

- pipe bearing;

- welding machine.

The process of making a jack with your own hands

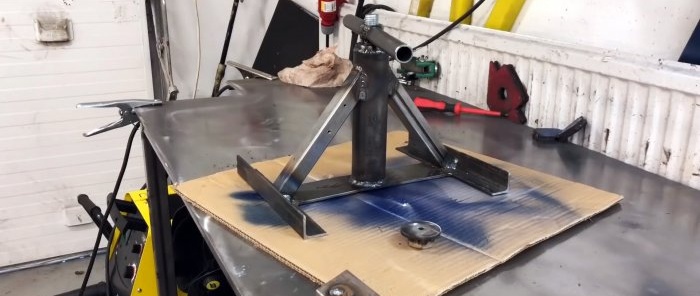

First of all, we weld the body of the future jack.We place the pipe, plate and corners evenly in the structure, where the corners are attached to both sides of the plate, and the pipe is in the center.

We grab the parts, check the geometry and weld the structure.

We mount a bearing in the upper part of the pipe. It is important that it has sufficient internal and external casing, because in the future it will be attached to the pipe.

We weld the bearing to the upper hole of the pipe. Screw a nut onto a threaded rod.

We insert it into the inner hole of the bearing so that the rod rests against the lower metal plate. We tighten the nut close to the bearing and weld it.

We weld two 20 mm tubes to the edges of the nut on both edges - these will be handles for turning the jack.

We cut out two parts from a square metal tube that will serve as diagonal stops for the jack. We rest the lower parts against the corners, and the upper parts against the body of our device. We weld the stops using welding.

We weld the second nut to a thick-walled round piece of metal (this can be a large washer with a small hole).

We screw the second nut onto the upper part of the rod - this is the retractable stop of the jack.

For aesthetic and practical use, the device can be coated with spray paint.

The jack is ready. Enjoy using it!