Content

1. Purpose of tow and how it works.

2. Varieties of sealing materials.

3. Method of sealing pipe threads with tow.

In plumbing work, tow is used to seal pipes and transitions connected by threads. It is made mainly from flax waste and is a coarse fiber of small size. If you wind the tow correctly, protection against leaks will be provided throughout the life of the pipeline. Answering the question of how to wind tow on a thread, it should be said that the quality of workmanship prevents the risk of leaks in the plumbing system.

There is a gap between the threaded connections through which water freely flows out of the pipeline. If it contains properly laid plumbing tow, then the gap becomes smaller, and as water penetrates into such a connection, the flax swells and the leakage stops.

Types of sealing materials.

The main materials that create a sealed layer between threaded connections include:

- plumbing tow;

- FUM tape;

- liquid FUM.

Silicone is used as an additional material to tow, but by itself, due to its properties, it cannot provide reliable protection of the connection from leaks.

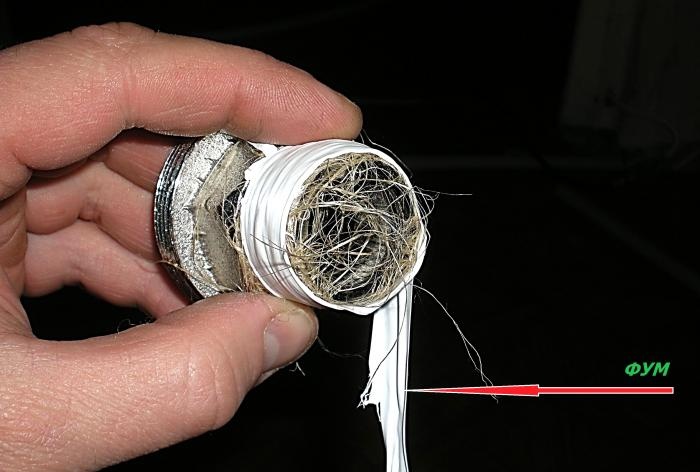

FUM is a thread winder consisting of Teflon tape that is not wetted by water and creates a water-repellent layer in joints.

Liquid FUM is a one-component blue sealant that, upon contact with air, slowly hardens and forms a fairly strong and dense filler that prevents water from leaking out of the system. But, if when using the above listed materials, pressure testing of the water supply can be done immediately, then after using liquid FUM, before checking the system, you need to wait a certain time, depending on the diameter and ambient temperature.

Method of sealing pipe threads with tow.

High-quality thread winding is carried out using the following materials and tools:

- two pipe lever wrenches;

- sanitary tow;

- FUM tapes.

Let's look at the procedure for obtaining a high-quality sealed threaded connection using the example of combining a union nut (American) with a 1-inch external thread and a check valve.

From the tow we separate a strand of length, approximately equal to 5 - 7 turns with a diameter of 1 inch and the density indicated in the photo.

We apply the resulting workpiece to the beginning of the American connecting element, while its thread should be directed towards you, and we wind it clockwise, along the course of the turns and back. We bring the end of the tow to the beginning of the thread and smooth it with our fingers, clockwise. In the end, it should look like in the photo.

Then, we wrap the FUM on this part clockwise so that it completely covers the plumbing flax and lays on it in 2 - 3 layers.

Teflon tape prevents the tow from rotating and moving off the part. We attach the American one to the check valve and, using keys, tighten it until a noticeable load occurs.

Such a combined winding of threads, with appropriate skill, almost always ensures reliable joining of two detachable pipeline elements. When all components of the system are assembled, it is necessary to pressurize it at a pressure of approximately 1 bar and inspect all threaded connections for leaks.

When using low-quality parts, the amount of winding should be slightly reduced, since during the process of flax swelling, forces arise that can lead to damage to the part.