The gun is designed to deliver a special composition (foam) to hard-to-reach places - assembly joints, cracks and openings that need to be sealed. To do this, the gun has a thin, elongated barrel, the end of which is equipped with a nozzle and a shut-off valve. The valve is controlled by a spring-loaded rod, which moves when the trigger is pulled.

At the top of the gun there is a special adapter (threaded fitting) for connecting a cylinder with a foam composition under excess pressure. Once the cylinder is attached to the adapter, the pressure is applied to the entire inside of the gun barrel. When you press the trigger, the nozzle valve opens and the foam under its own pressure is delivered to the desired location.

Inside the adapter there is a ball spring valve, which is the subject of today's discussion. It opens under the influence of foam pressure and operates in one direction.When removing the cylinder from the gun, the ball is pressed against the valve hole by a spring and prevents the back ejection of residual foam through the adapter, remaining in the barrel under pressure. The feature is definitely useful.

The problem is that, despite following the operating instructions and regularly cleaning the gun after finishing work, the remaining foam in the ball valve dries out, preventing the further flow of foam from the next cylinder.

The solution suggests itself - simply dismantle this auxiliary valve.

So let's get started.

Necessary tool

To complete the work we may need:

- electric drill;

- a set of drills of different diameters;

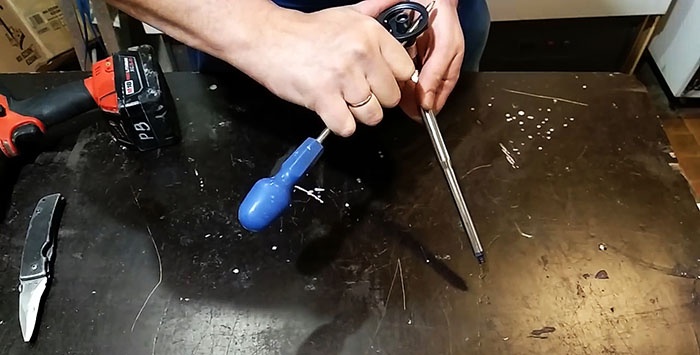

- a screwdriver or a thin steel rod for use as a wrench.

The content of the work

Unscrew the removable part of the adapter to which the cylinder is attached. If this cannot be done by hand, use a wrench.

The required valve is located inside the unscrewed adapter. The valve itself is a plastic sleeve with a hole. Inside the bushing there is a ball pressed to the hole by a spring.

In my experience, it is usually not possible to remove the valve bushing by simply picking it up with something. Therefore, we will drill out the valve. We select a drill of a suitable diameter. The drill bit should be thinner than the hole in the adapter's metal body to avoid damaging it, but still thick enough to drill out the plastic valve.

We carefully drill to a shallow depth, after which the remains of the plastic sleeve with a spring and ball are easily removed. This completes the main part of the work.

If necessary, clean the internal hole of the adapter from any remaining dried foam and screw it into place.

The gun is ready for use again.

Warning

When operating the gun in this form, changing the cylinder may be accompanied by splashing of foam residue. To avoid this, when removing a cylinder (especially an underused one), you should pull the trigger at the right moment to relieve pressure in the barrel, while oriented the barrel and gun adapter in a safe direction.