The heat exchanger is installed on the chimney of any stove and increases its output and efficiency by more than 2.5 times. This significantly increases fuel economy and reduces warm-up time.

The essence of the work is simple: through the stove chimney, in addition to smoke, heat is also released, which can still be used. The heat exchanger takes this heat and gives it to the room in which it is located. Very good results are obtained with stoves that run on solid fuel.

Materials

- Metal bucket for construction or paint materials.

- 8 pieces of 1/4" steel pipe.

- 1 piece of 1/2" diameter steel pipe.

- 2 pieces of 6" pipe to connect to the chimney.

- Steel sheet.

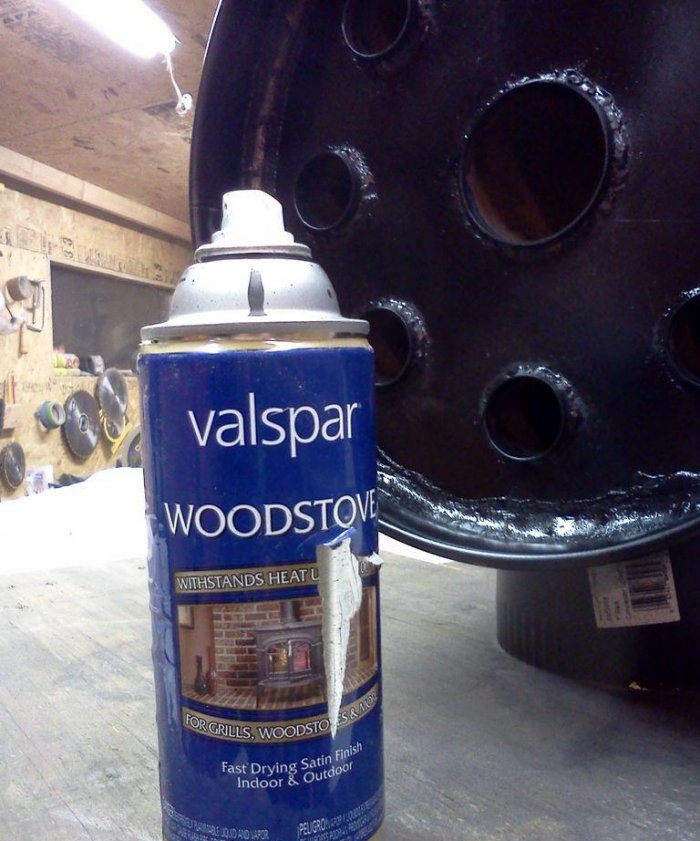

- A can of high temperature paint.

- High temperature cement for fireplaces - 1 tube.

Manufacturing a heat exchanger for a furnace

We take a metal bucket and measure its depth. We cut the steel pipe into 8 even sections with a length equal to the depth of the bucket. And one ninth piece of larger diameter.

We will clean the edges from burrs and rust or any other deposits.

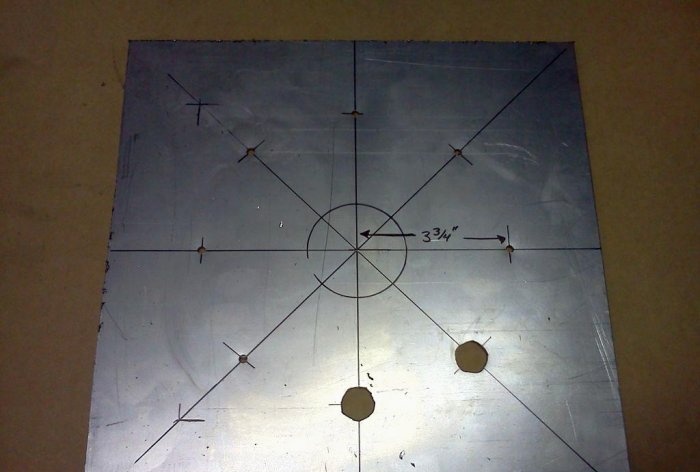

From a steel sheet we cut a square into which the diameter of the bucket will fit.Let's draw the diameter and hole for the large pipe in the center. We will also mark 8 holes for pipes along the center line.

Drill all the marked holes with a thin metal drill.

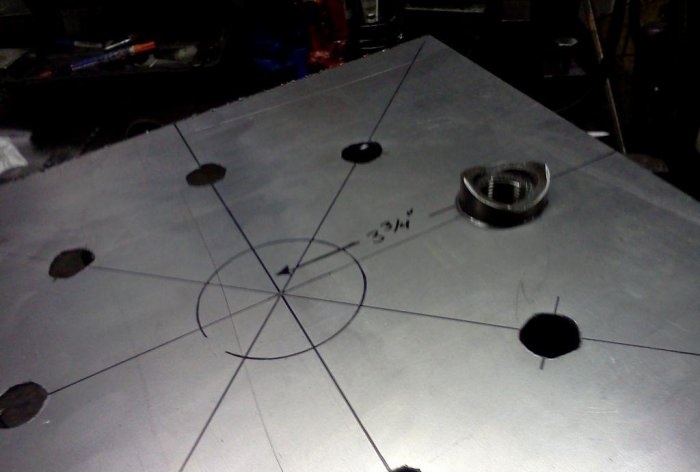

I will make 8 holes of the required diameter using a homemade extrusion device.

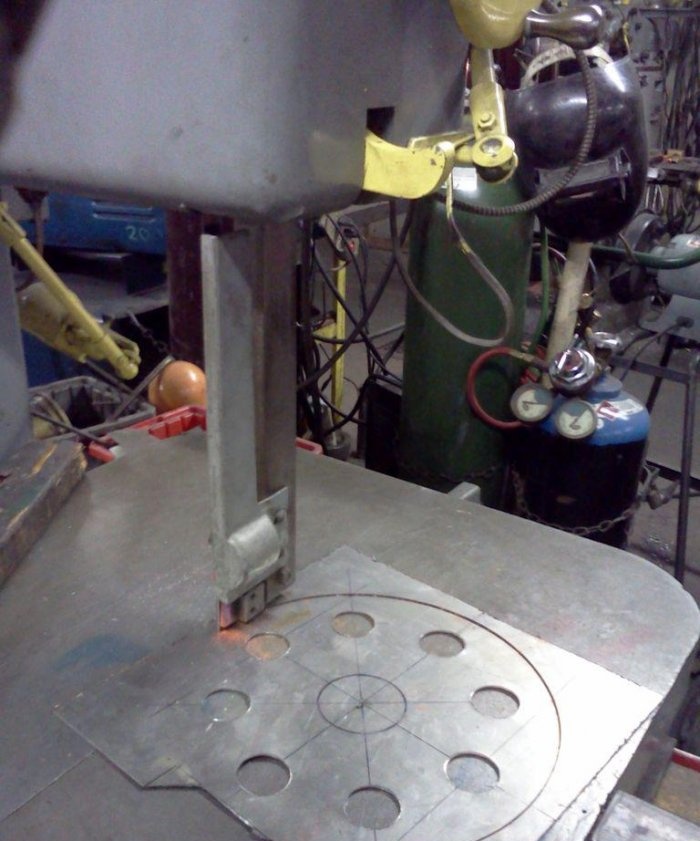

We cut a circle out of a square on a band saw.

I will cut out the central hole for the 1/2-inch pipe by drilling multiple times along the diameter.

You need to make two such parts.

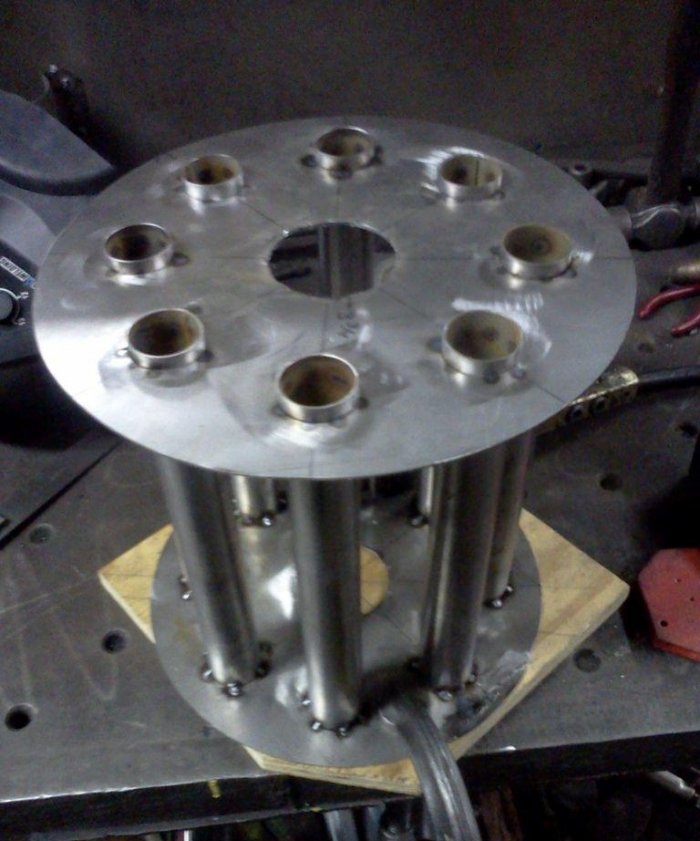

Now everything needs to be welded, but for this a device will be made from thick wood.

The fact is that welding the entire structure exactly is not so easy; there is no necessary fixation.

We drill 8 holes in the board.

Next, we install all the parts on it and weld one to the other one by one.

First, we fix it with welding points, and then we scald each element in a circular manner.

First on one side, then on the other.

We take a steel bucket and burn it over a fire, removing everything unnecessary from the surface: paint, labels.

We use a grinder to remove soot using a cleaning attachment, and then saw off the bottom of the bucket.

On the sides of the bucket you need to make two holes for the entrance and exit of the chimney.

We mark and cut the pipe section to make a skirt.

We install in the holes with a bend.

We fix it by welding. The metal of the bucket is thin and therefore cannot be sealed using circular welding - it will burn out.

We insert the core inside and fix it with drops of welding.

Since a high-quality and airtight seam cannot be made, everything must be sealed with a special high-temperature cement putty, which is usually used in the construction of fireplaces.

We coat all joints.

Then we take high-temperature paint. It is used for painting furnaces, mufflers and manifolds in automobile workshops.

Cover in two layers.

We install it on the stove pipe.

We install a household room fan at the back for ventilation.

Let's revive the oven.

Without airflow, the central pipe becomes red hot. And if you take measurements with a pyrometer, the temperature is approximately 470 degrees Celsius.

As soon as you turn on the fan, the temperature drops by half and the heat is well distributed throughout the free space.

I found a small stationary fan and attached it to some kind of mounts.

We turn it on and measure the result of the work.

The result of the heat exchanger

I have a fairly large room. And to heat it from -10 to +20 degrees Celsius, from the start of the boiler, previously took 3.5 hours. Now, when using such an air heat exchanger, it takes about one hour, which is three times less. The result is quite satisfactory, especially with regard to saving firewood or other fuel.