A lathe is a universal piece of equipment that allows you to perform various types of work, including the production of taps for threading. Let's look at how to do this using an M14x2.0 mm tap as an example.

What you will need:

- steel reinforcement with a larger diameter than the tap size;

- lathe;

- set of turning tools;

- drills 4 and 6.5 mm;

- emery;

- forge or gas burner.

Tap making process

Before you start making a tap, you first need to estimate the dimensions, having thought through at least an approximate drawing of its end part. Its circumference will be 14 mm in diameter. To make edges along its edge, you need to drill 3 holes at equal intervals. Their diameter will be 6.5 mm. Thus, the workpiece must have a diameter of at least 19 mm, but preferably 21-22 mm.

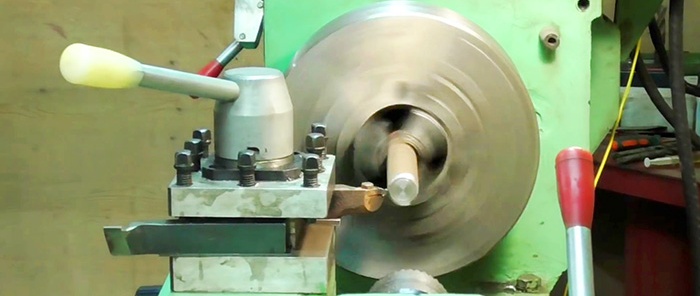

On a lathe, it is necessary to turn the workpiece to the design diameter, in this case 22 mm, and cut it to the required length. After this, one of the ends is leveled and a shallow groove with a diameter of 14 mm is marked on it with a cutter.

Having trimmed the workpiece, you need to clamp it completely in the chuck and scratch 3 longitudinal marks along the left edge of each cam with a scriber.

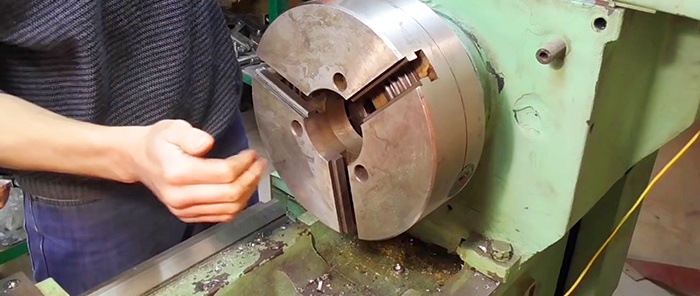

Then you need to drill 3 holes at the end of the workpiece with the centers located in the groove. To do this, you need to unclench the cartridge and swap its jaws. This will disturb its alignment, and when compressed, 2 cams will come together, and one will remain apart. By clamping the workpiece in the chuck, you can achieve its displacement.

This will allow you to make a shift when drilling 3 end holes. When installing the workpiece and subsequent displacement, it will be possible to navigate by longitudinal scratches. The holes are first made with a thin drill and then drilled out to 6.5 mm. The center of the holes should be in line with the 14mm diameter circular groove at the end.

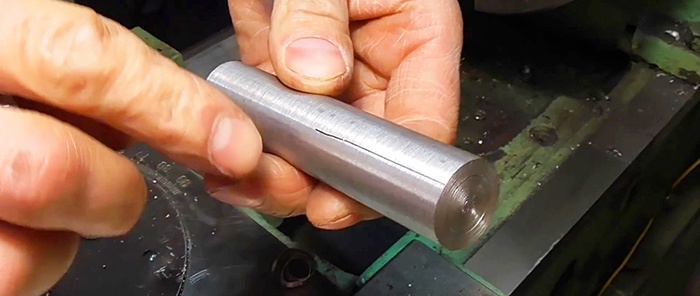

After drilling, you need to turn the workpiece over and grind its shank to the diameter of the existing tap holder. Then the side with the holes is machined to a diameter of 16 mm. The chamfer is immediately removed.

Next, since this is an M14 tap, threads are cut on the workpiece in increments of 2 mm. Having finished with the thread, you need to grind the shank using sandpaper to fit the square of the tap holder.

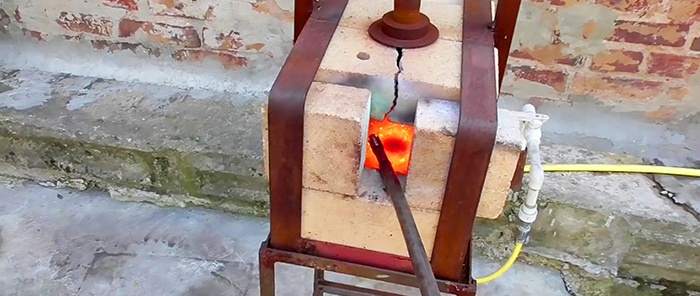

After this, the edge of the tap with the beginning of the thread is heated red-hot in a heater or with a burner and dipped into water. This way the whole thing is not hardened, so it is less likely to break during operation.

After hardening, you need to sharpen the leads on the tap so that it can be screwed into the workpiece with a 14 mm hole.

The resulting tool can be used for cutting threads in almost any workpiece.

Since it is still not made from the right steel, it wears out little by little when working with ferrous metals, but it will last no less than the purchased analogues from China.