Will need

- Three tin cans.

- Soldering iron (preferably gas, but a regular one is also possible), tin and flux.

- Engraver with 6 mm grinding stone.

- Thread and cap from a bicycle inner tube (brass cap!).

- Rubber sealing ring for threaded neck.

- Scissors.

- Marker.

- Solvent with a rag.

- Pump.

- Solvent resistant paint.

- A piece of sponge.

- Can opener.

- File.

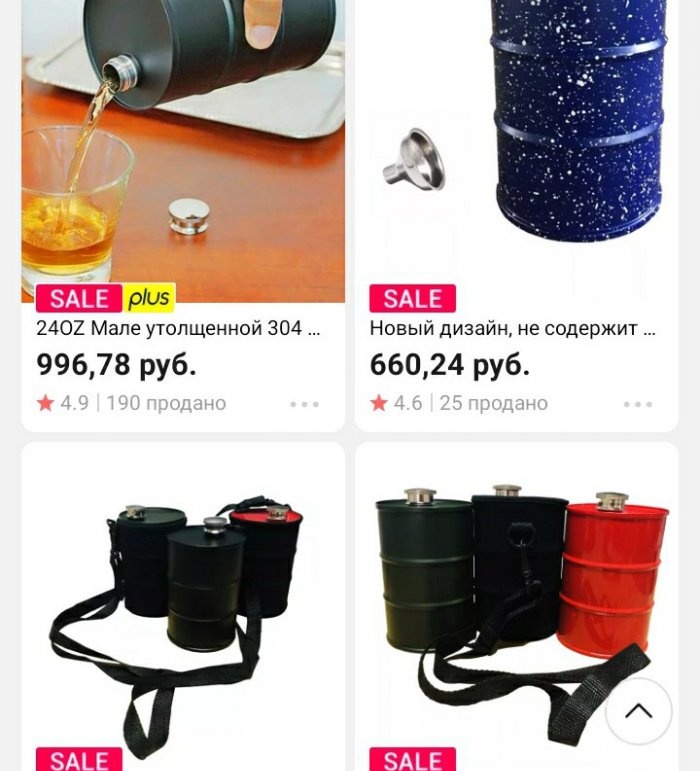

Making a "Barrel" flask

There is nothing difficult in the upcoming work if everything is prepared correctly. When soldered, tin itself spreads over tinned areas and strips. First, let's prepare the jars. You will need three of them. I simply bought three canned fish I liked in the store, in identical jars, ate them, and received the required material. We take a can opener and open the canned food. The first, as expected, is on top, this will be the lower part. The second - from the bottom, this will be the upper part. And the third one needs to remove both the top and the bottom - this will be the middle. Next, we try the cans on each other; We set them as evenly as possible, and mark the joints with a marker. Now you need to remove the food varnish from the tin in those places where the metal parts touch. On all the details. You can use a file, but I used an engraver to speed up the process. We treat the cleaned areas with flux and carefully tin them, not sparing the tin. Now you need to solder the thread into the upper part of the future barrel. This is important! FIRST you need to solder the threads, then proceed to soldering the remaining parts. If you leave the thread until last, then the gases from soldering, inside the barrel, will have nowhere to go, and they will leave many pores in the sealed seams. All our work will be in vain - the barrel will leak like a colander! So, mark with a marker on the top lid of the barrel the place where the neck should be. We cut a 6 mm hole with an engraver. About the same as a real barrel.We tin the edges of the hole, tin the base of the thread, and solder the thread to the hole. Like this: We wait until it cools down and we can begin the main assembly. Everything is as simple as shelling pears here! All you need to do is heat the joined parts of the barrel with a soldering iron, and have time to apply tin to the joint. Gravity will do the rest - it will evenly distribute the heavy solder around the entire perimeter in all tinned places. And, nevertheless, you still need to carefully inspect the soldered joint afterwards. Wipe it with solvent, removing soot and flux residues, and add tin in places where there is little of it. All factory seams should also be soldered - during heating they invariably become deformed and, in the future, may begin to leak. After soldering the parts into a single whole, you need to remove with a file all the frozen drops of solder that have protruded out. This completes the main assembly. Now you can do the final work; adjusting the lid, checking for leaks, and painting. My cap had a through hole. Therefore, I simply cut off its conical top with an engraver, and soldered a piece of brass into this place. Here's what happened: All that remains is to check for leaks and paint the barrel. We take the pump, screw the hose onto the thread of the barrel, release the barrel into the water, make a couple of pumps, and watch carefully. A leak, if there is one, will immediately reveal itself as air bubbles. Everything went smoothly for me the first time - not a single bubble. If anyone discovers a leak, you need to mark this place with chalk and, when the water dries, heat it with a soldering iron and add tin there. The leak will be fixed. Now painting.Since I am going to use this flask to transport fuel - alcohol for a kerosene stove, or lighter fluid, the paintwork must also be resistant to solvents. Having selected the desired enamel, we begin painting. We take a piece of sponge, dip one third of it into the enamel, and with progressive movements, poking, apply paint to the entire surface of the barrel. Having covered the entire surface, we leave the barrel to dry. After the paint has dried, apply a second layer. This is necessary in order to hide minor irregularities and scratches from the file. Let the paint dry according to the instructions on the package. And, finally, we put a rubber sealing ring on the base of the thread for tightness. Well, the flask is ready. I didn’t paint the lid to make it look more like a real barrel. You can use it. Theoretically, of course, you can store and transport in this flask not only flammable liquids for kindling, but also alcoholic drinks such as vodka and cognac. But I wouldn't recommend doing this; After all, solder contains lead. This is a heavy metal that has a bad tendency to accumulate in the body. If you need a flask for alcoholic drinks, purchase special solder in the store, pure tin, without lead impurities. It will, of course, cost a little more, but it will keep you healthy. So, let's summarize: my flask cost me 320 rubles - three canned goods for 150 rubles, solder for 70 rubles, and a can of gas for a soldering iron for 100 rubles. Against the minimum price in the store for 700 rubles. The flasks are almost identical, and the benefits are obvious! The only difference is that it is not advisable to store drinks for internal consumption in my flask.But for me personally, this is not so important.Watch the video

How to make a custom stationery knife with your own hands - https://enn.washerhouse.com/7134-kak-sdelat-kastomnyj-kanceljarskij-nozh-svoimi-rukami.html