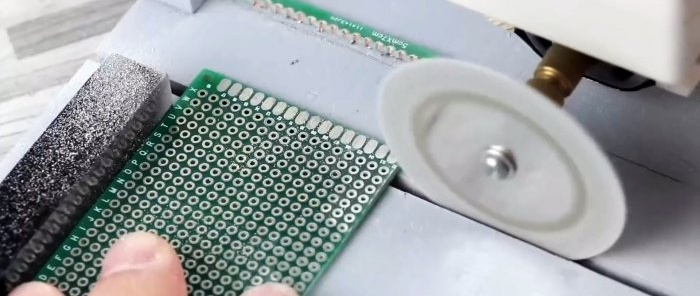

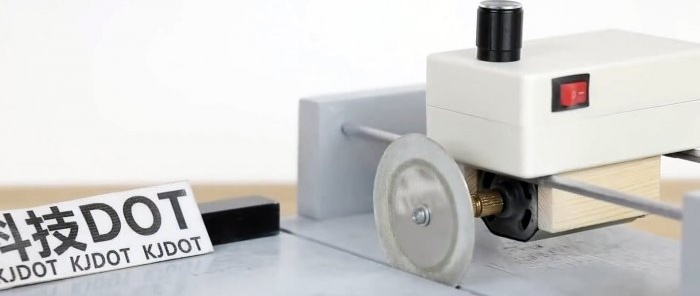

For accurate and quick cutting of circuit boards, as well as sheet plastic and other thin materials, you can make a miniature desktop machine. It is accurate and very quiet, so it is even suitable for use in an apartment. This is ideal equipment for those who do not have their own workshop.

Materials:

- plywood 10 mm;

- rail 10x40 mm;

- plastic box 80x50x30 mm - http://alii.pub/5m5npj

- smooth steel bar 4 mm;

- telescopic antenna;

- DC electric motor 480 - http://alii.pub/5q1rlj

- diamond cutting disc 50 mm - http://alii.pub/5q1ocv

- collet chuck for 3 mm shaft - http://alii.pub/5q1o96

- screw M3 20 mm;

- PWM regulator - http://alii.pub/5q1o2r

- push button switch - http://alii.pub/5mk6b7

- power connector - http://alii.pub/5m5nij

- power supply 12V - http://alii.pub/5q1o0m

Manufacturing process of cutting machine

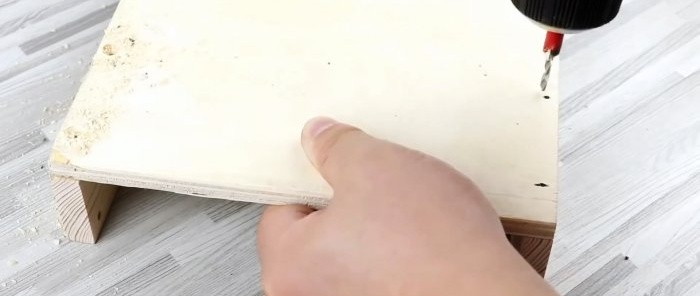

A piece of plywood 260x200 mm is used as the base of the machine. In addition to it, you need to cut 2 blanks from the slats measuring 80x40x10 mm, and also one 150x10x10 mm. From a 4 mm rod, 2 pieces of 200 mm are cut.

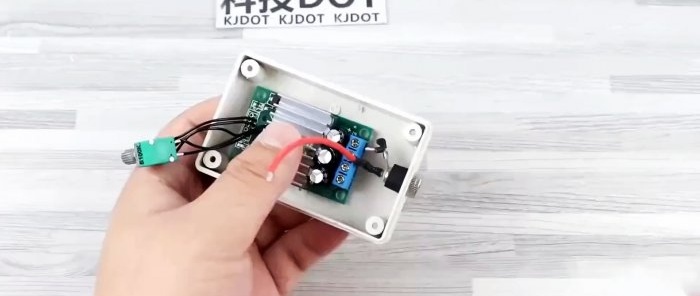

A hole is drilled in the junction box for the power connector.

It is installed inside, and a PWM speed controller is glued next to it. It connects to the connector. The handle from the regulator must be brought into the lid of the box.

A push-button switch is cut into the side and connected.

2 tubes from a telescopic antenna are glued crosswise to the bottom of the box with two-component glue, which will serve as guides for moving the engine.

Then the motor is glued in. 2 slats are placed on the sides with glue, and everything is pressed on top with a plate of tin.

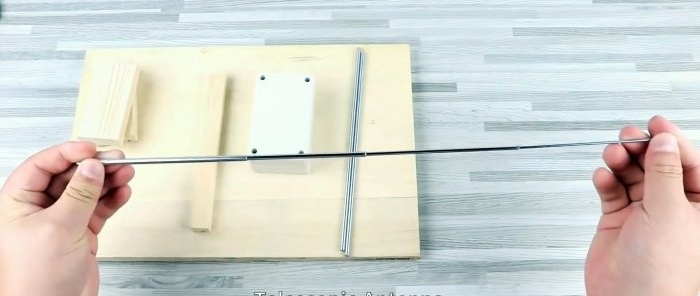

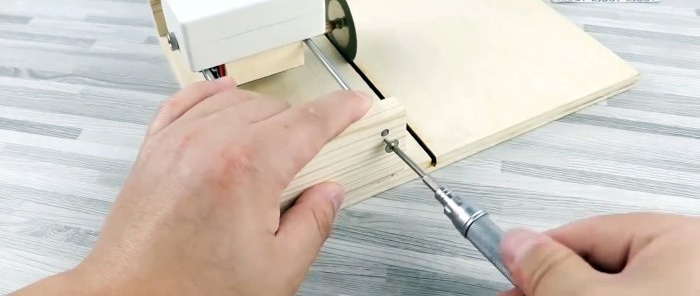

Linear shafts are inserted into the guides. Then their edges are inserted into previously drilled holes in the 80x40x10 mm slats.

The workpieces are screwed to the base of the machine along with linear guides and a motor.

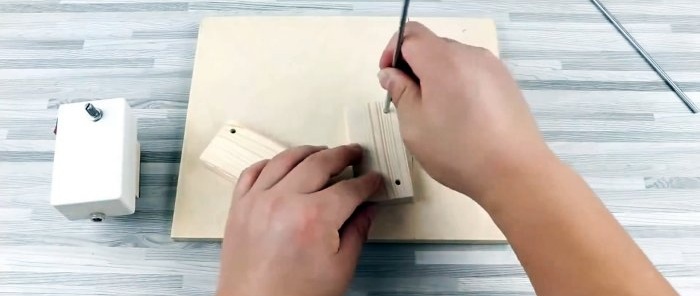

You will need to make a cut on the sawing surface itself so that the cutting disc on the motor shaft can move along it freely. It is installed using a collet chuck and a tightly clamped screw. A screwed 150x10x10 mm rail will serve as a sawing stop.

To reduce vibration, rubber feet can be screwed to the machine.

It can be painted if desired. Then the power supply is connected to the connector on the box.

The result is a quiet precision machine that takes up virtually no storage space.