Factory cutters and side cutters usually have little strength, so they require frequent sharpening, and when cutting hard metals, damage to the cutting edges is possible. But with a little time and effort, you can make an almost eternal instrument.

Will be needed

- Old pliers;

- replaceable inserts for turning cutters;

- M3 bolt – 2 pcs.;

- a piece of hacksaw blade;

- nylon thread;

- acrylic urethane varnish.

Manufacturing process

Closer to the hinge, cut off the jaws of the pliers.

We remove part of the thickness of the remaining bases of the jaws to the height of the plates. We trim the notches with a file, but since the steel is hardened, we release it by heating it with dry alcohol and a turbo lighter.

We place the plates in the recesses and mark the places where the holes are drilled to secure them.

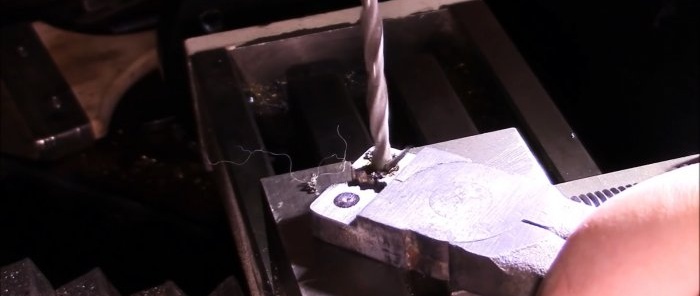

We drill holes with a hard drill at low speeds and cut the threads with a tap.

We fasten the plates with bolts with countersunk heads or hexagon heads.

If there is a large gap between the plates, then we file down the support points of the pliers.

We form the cutting edges on the plates, securing them in place with bolts, a diamond or emery wheel and a needle file.

If there is play in the pliers, then lightly rivet the hinge before starting work. The final sharpening of the plates is carried out with a diamond needle file.

For ease of operation, we will equip the nippers with a spring made from a hacksaw blade with the teeth removed.

We secure the spring on the inside of one of the handles with a nylon thread, and press the upper end to the second handle.

To fix the nylon thread, we coat it with acrylic-urethane varnish, which strengthens and hardens after drying. You can also secure the spring by soldering.

Our nippers hold an edge for a very long time when working with hard materials, and do not need it at all when working with soft ones.