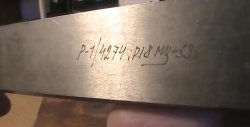

To successfully drill a hole with a diameter of 2 mm in the hardened and durable tool steel from which files are made, the first drill of the specified diameter will not work. Files are made of unalloyed improved steel with a carbon content of 1 to 1.3% grade YUA-U13A or alloyed chromium steel grade ShKh15 or 13X. The drill must have a certain hardness and strength, but not less than that of the material being processed.

This, for example, cannot be done with a tile drill available, since its diameter is more than two mm. Suitable drill bits can be buy on Aliexpress with a diameter of 2 mm (Link - https://alii.pub/6ls28y). Such drills are made of metal-ceramic, have a hardness of 65 Rockwell units and cost about 500 rubles.

Drill, which was used to drill holes in the file, was sharpened several times, so that by the end of the experiment it was shortened by half. So drill It is also easy to drill holes in a knife made of high-speed steel grade R6M5, which has great strength and hardness.Despite the fact that it is fragile, it is almost impossible to bend or break it.

How to drill a 2mm hole in hardened steel

To preserve the drill, it is better to use a drilling machine to minimize backlash, and be sure to use oil when drilling. As a result of drilling, it turned out that the metal of the file turned out to be harder than the tool steel from which the knife blade was made.

The drill was repeatedly sharpened on a diamond disc, since the hardness of the metal from which it is made is very high and it can scratch the surface of glassware without much effort.

We drill the file with a sharpened drill, securely clamping it in the screwdriver chuck with periodic use of oil for cooling, lubrication and improved removal of chips from the working area. This is much more difficult than using a drill press and requires high skill and a steady hand. One wrong move or incorrectly selected mode and drill may break as it is quite fragile.

You need to be especially careful before finishing the file drilling operation. When the drill comes out from the back of the file, it may become pinched and the drill will suffer from brittle fracture.

It is better, of course, to drill a hole with a diameter of 2 mm not with a screwdriver, but on a drilling machine, and then the process will be much more productive, of higher quality and more economical. Experiments with drilling metal with a file and knife showed that drill quite strong, exceptionally hard, but at the same time fragile.