Materials and tools

For production, you will need:

Tools:

- Drill.

- Bulgarian.

- Hand tools.

- Welding machine. etc.

Materials:

- Engine.

- Metal strip.

- Plank (base).

- Housing (for electronics).

- Fasteners (bolts, nuts, etc.).

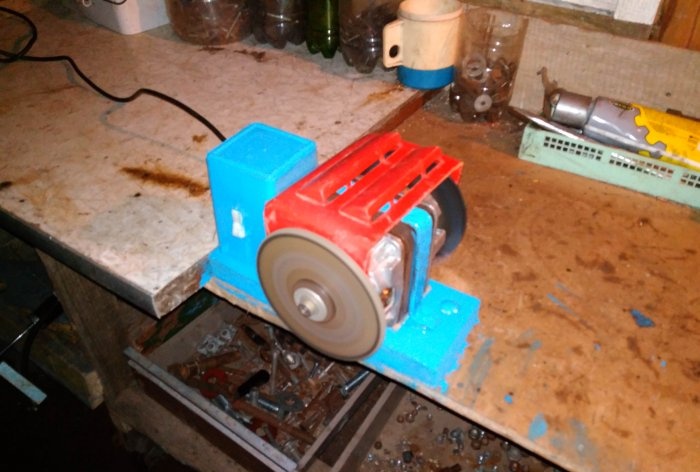

Making a sharpener with your own hands

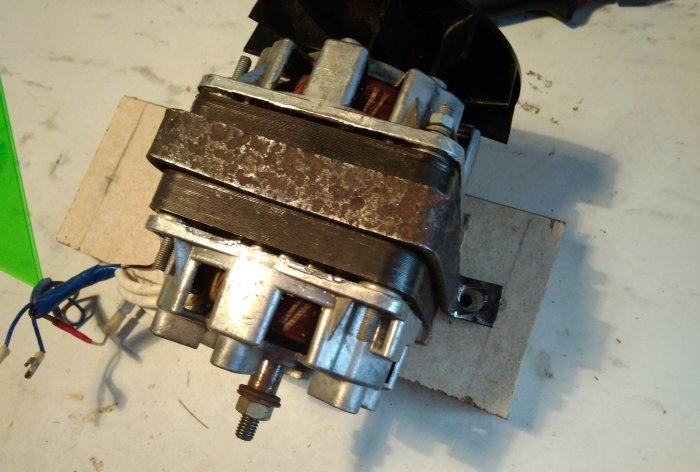

And so let's go. First, let's take measurements of the engine for future mounting.

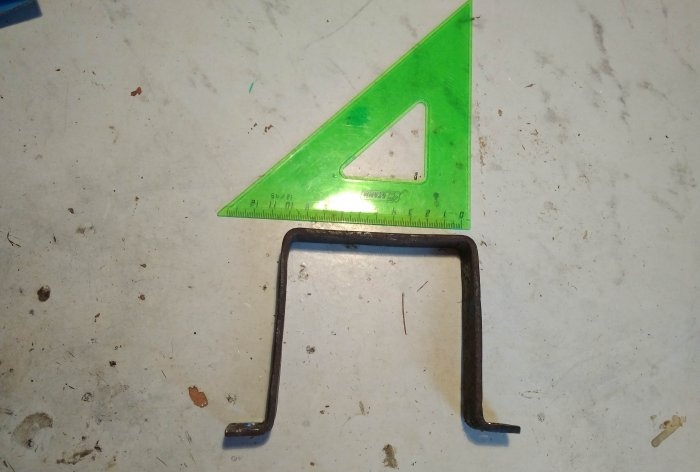

Then, using a vice and a hammer, we make such a bracket from a metal strip.

We drill two holes at the ends of the future fasteners.

On the board itself we drill two holes for the bracket itself.

A piece of fiberboard will serve as a gasket under the engine to dampen vibration.

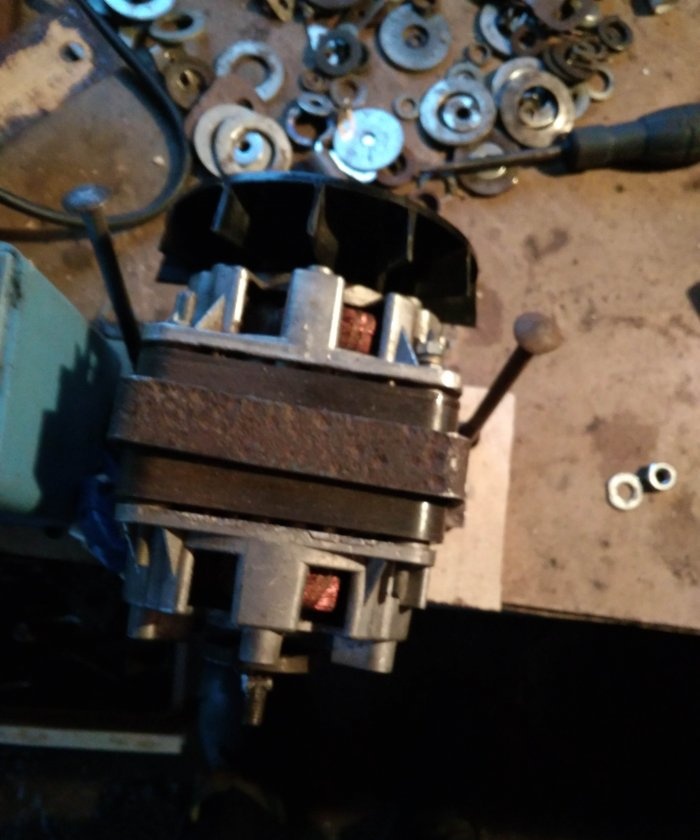

We install the engine.

We fix it with a bracket, and tighten it all with bolts, we adjust washers under the heads of the nuts and bolts.

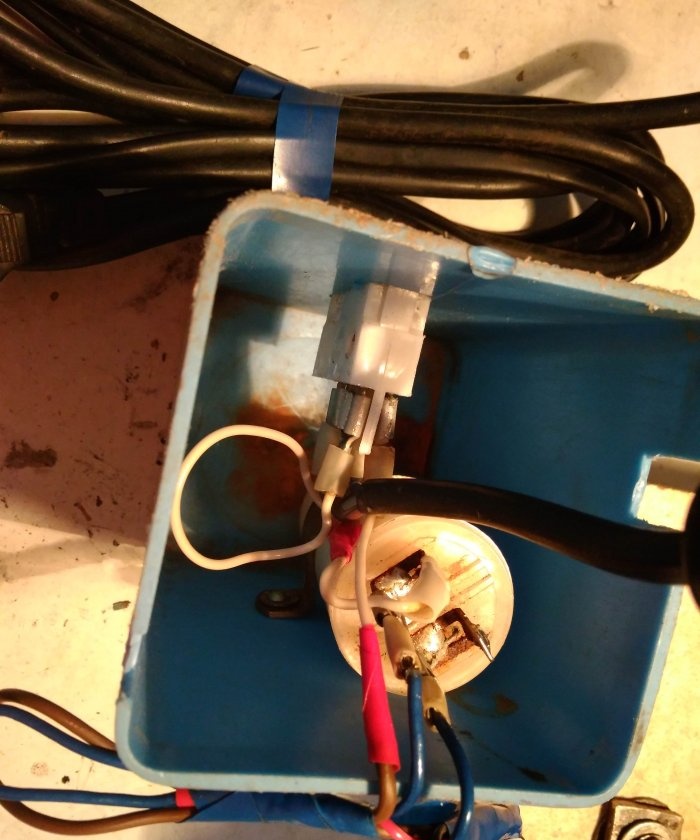

I will use a box as a body. In which we make two slots for the wires.

Using standard fasteners, we fix the capacitor on the body itself.

Install the switch.

We connect the electronics, the main thing here is not to make a mistake when connecting, it is best to have it with you multimeter, or a diagram (there are plenty on the Internet).

Initially, I wanted to install a speed controller, but since the engine is low-revving, I connected standard electronics.

We make four holes in the body for screws.

And twist it at a slight angle.

To attach the abrasive we need two important parts, these are two washers from an old grinder.

We install one of the washers as in the photo, here accuracy plays an important role.

Using welding, we grab the washer, and the fastening is almost ready.

Next, we grind the washer off on both sides as in the photo so that it sits well in the grooves of the second washer.

We install the abrasive.

Then the second puck.

A small puck.

Counter puck.

And tighten the nut to 13.

What remains from the same washing machine is the engine housing, from which I will make a protective cover from dust and dirt.

Let's cut it off.

Let's try it on.

And we install.

I will attach the sharpener to the table with two bolts.

Before painting, clean the surfaces.

And we paint.

Result of work

The sharpener is ready.

The result is a sharpener like this, there are a lot of uses; if desired, you can make polishing wheels, emery wheels, etc.