Washing machines often fail without their motors being fully functional. Its power and actual speed are well suited for the use of this spare part in the manufacture of homemade machines. As it turns out, such an electric drive is also an ideal solution for installation on a homemade grinder.

Materials used

It didn't take much to make:

- motor from a typewriter;

- its original starting capacitor;

- part of the sheet metal covering of the machine;

- 4 rubber feet from the washing machine;

- plywood sheet;

- a 5 cm piece of thick-walled tube with an internal diameter of 14 mm;

- 2 identical bearings;

- glass sealant;

- sheet metal with a cross section of 8 mm;

- corner 63x63 mm;

- profile pipe 40x40 mm;

- profile pipe 30x30 mm;

- extended nut;

- steel strip with a cross section of 10 mm;

- furniture gas shock absorber;

- power button;

- plastic plugs 30x30 and 40x40 mm;

- bolts and nuts M12, M10, M6 and M5.

The main detail of the entire structure:

The process of making a grinder from a washing machine motor

First I made tension rollers.

These are factory metal ones. Ours will be homemade, wooden.Moisture-resistant plywood is suitable for their manufacture; its thickness is not so important.

You need to make pancakes out of it, which will then be glued together into a roller. First, I install a wood bit with a diameter of 102 mm on the drill. I cut out 9 plywood pancakes for the drive roller. The number of circles depends on the thickness of the existing plywood and the width of the tape that will then be used.

Now the pancakes need to be glued together. First you will have to sand them a little to remove chips from the crown. I grease the side of the circles with PVA glue and form a wide multi-layer roller. For normal gluing, I fix the workpiece under a press.

While the drive roller is drying, you can make a driven roller. It uses a 64 mm crown. Again, using a drill, I cut out 9 pancakes from the same plywood and glue under pressure.

To prevent the rollers from delaminating after they dried, I made 2 side holes in them and additionally tightened everything with a pair of screws on each side.

I balance the rollers in a lathe, grinding down the irregularities a little and making the workpieces smooth.

To secure the drive roller to the motor shaft, you need to make an adapter. For this, a piece of thick-walled tube is used.

In most cases, a pipe with an internal diameter of 14 mm will be required. To tighten the tube on the electric motor shaft, I drill a hole and cut an M5 thread. At the second end of the tube I weld an M12 bolt.

I expanded the drive roller hole to fit the tube by half the depth. The remaining narrow part will contain the thread from the M12 bolt.

You need to install a pair of bearings in the driven roller, one on each side. Their size is not so important; you can use any, as long as it has a suitable internal diameter.I prepare the bearing housings on a lathe.

To make the surface of the rollers smoother, I decided to coat them with glass glue. To do this, I fix them one by one in a lathe and coat them evenly around the perimeter and ends.

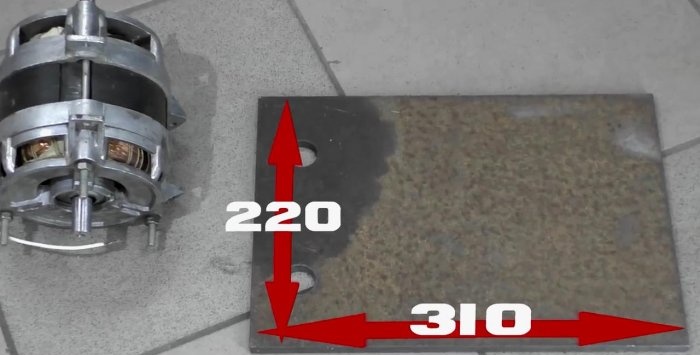

Now you need to make a frame for installing the electric motor. As a base I use a metal sheet with a cross section of 8 mm. I cut out a rectangle with sides 220 by 310 mm.

To directly mount the engine you will need 2 corners. I am preparing pieces 130 mm long. The 63rd corner was ideal for the electric motor.

I lay the steel plate on a flat surface, install the angle and the motor, then make markings for drilling the mounting holes with a 6 mm drill.

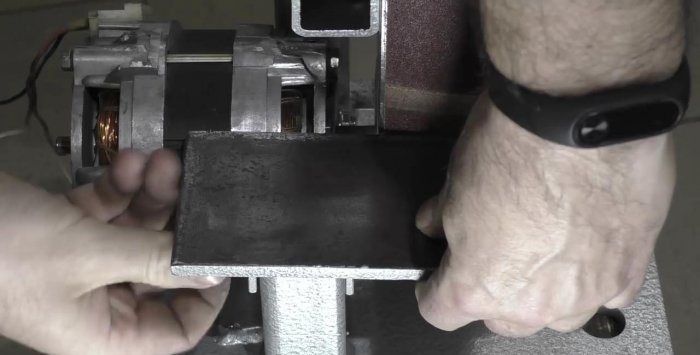

To prevent the corner from interfering with the drive roller fixing bolt in the future, you need to select metal close to the shaft. The easiest way is to cut out a small triangle.

I mount the angles on the electric motor using four M6 nuts with a press washer.

I install the motor with the mounts in place, make markings and weld the corners to the base of the machine.

I cut a piece 300 mm long from a 40x40 profile pipe. I make another piece of the same length, but from a 30x30 mm profile pipe.

Now you need to make a mechanism for adjusting the tape. To begin with, I take an elongated nut and grind its edge.

I weld it to a steel strip with a cross section of 10 mm. I drill a hole on the strip and cut an M10 thread for the bolt on which the driven roller will be fixed.

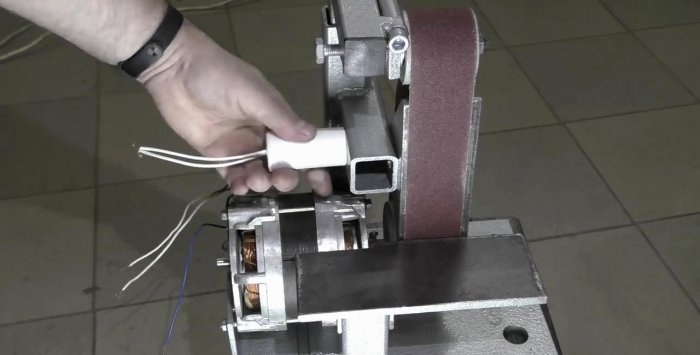

Then I welded an L-shaped blank from a previously cut 30x30 square pipe. I welded nuts to it to secure the strip made. I also secured the nut and bolt on the perpendicular wall of the square opposite the head of the bolt on which the driven roller will be mounted.By tightening or unscrewing a short bolt, you can change the angle of the roller, thereby adjusting the machine.

I place a 40x40 profile pipe vertically on the machine platform and weld it. At the same time, I try on the place so that the driven roller stands opposite the driving one, which in turn is fixed to the motor shaft.

To ensure smooth tension of the tape, you need to install a gas furniture shock absorber between a 40x40 vertical pipe and a 30x30 L-shaped roller holder.

I make a support platform for the machine from available materials. Using a small piece of profile pipe 40x40 and a 63rd angle. I made a cutout on the pipe to increase the welding area. I attached the corner with bolts, since it will need to be removed for maintenance. I made all the blanks without preliminary dimensions, simply adjusting them to the location.

And now I’m preparing a table for resting the workpieces being turned. For this I use the same sheet metal with a cross section of 8 mm. I made the width of the table 80 mm.

I'm preparing the base for the table. To do this, I take a 40x40 pipe with a length of 120 mm. I drill a hole in it, sharpen the end in a semicircle and cut an M10 thread. I make small ears out of sheet metal. They will act as loops. I weld the ears to the tabletop.

Now I cut a thread in the sole of the machine for 4 soft rubber feet to minimize vibration. They can be removed from a broken washing machine. I immediately cut off a blank from its body to make a protective casing. I cut a 130 mm wide strip along the entire length, then shortened it locally.

In a vice, using a hammer, wooden blocks and other devices, you need to bend the strip and drill mounting holes in it to get a full-fledged protective casing. All details are ready.

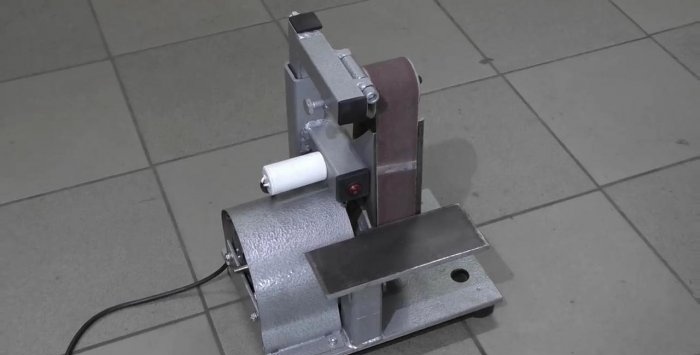

Having all the necessary parts at my disposal, I paint the elements of the machine.

It's time to assemble. Everything is assembled like a constructor. You'll have to tinker a little with the button, capacitor and soldering of wires. I was even able to find 2 plastic plugs for the 30x30 pipe and one for the 40x40, so everything looks good.

As the test showed, the engine power is sufficient for full operation of the machine. Thanks to the use of a gas shock absorber, you can install sanding belts of various lengths on the rollers, thereby getting the opportunity to use factory consumables rather than gluing the sanding belt yourself.