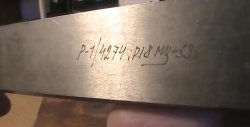

Hi all! I decided to show a test of a carbide drill, which can be purchased for about $1. It is popularly known as a “feather” (feather drill) and was originally intended for drilling tiles and tiles. In practice, it is already known that such a drill does an excellent job with stone, concrete, and glass.

You can buy it on Ali for half a buck or even cheaper - Ali Express.

It also works well on high-alloy steel. For example, drilling a file 5-8 millimeters thick with such a drill is not a problem.

I decided to give the task a more difficult task: drill a hole in the ball from the bearing, with a diameter of 35 millimeters.

Drilling the ball from the bearing

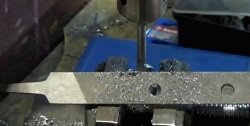

Securely fasten the bearing ball in the cleats of the drilling machine. We fix the feather drill into the chuck.

First, we start drilling without lubrication. The drill moves a little from side to side. There is no need to press too hard.

After the drilling point is filled, add oil and continue drilling. Now you can slightly increase the pressure. In general, you need to do everything carefully and slowly.

Periodically raise the svetlo and add oil to the hole.

We continue to drill the bearing.

We had almost reached the end and shavings began to fall from below. A little more and the drill will go right through.

The result is a through hole in the ball.

This is a simple technology for drilling carbide, hardened steel or even tool steel.

Of course, such questions do not often arise in life, but cases do happen.

Especially if you need to drill into concrete with reinforcement inside, then I recommend doing it with just such a drill. Since it will drill well into both concrete and reinforcement inside it.

The price is quite reasonable, at least in China. Sometimes they criticize domestic analogues, but personally, I always try to take a foreign instrument, since life experience shows that this is exactly what needs to be done.

See you friends!

Watch the video

For a clear example, see the video.