The correct choice of a disc for an angle grinder (angle grinder) is a key condition for achieving the desired result when performing certain jobs. In this case, you should not only focus on the dimensions of the circle, including thickness, landing or maximum diameter, but also the purpose, compliance with GOST and other parameters. After all, each type of nozzle is effective only when solving certain problems.

Purpose and types of disks

Grinder discs are a consumable tool in the form of a circle (bowl) with a special cutting, cleaning, grinding or other edge and a mounting hole for fixing on the angle grinder shaft. Depending on the execution and purpose, there are several varieties:

Cut-off

They are characterized by a small thickness of 1–3.2 mm with an outer diameter of 115–320 mm and a specific cutting edge. Often they stand out from other analogues with a certain marking color, taking into account the material for which they are intended for cutting:

- For metal:

Steel wheels for various metals and their alloys with abrasive surfaces made of crystalline alumina or synthetic corundum (electrocorundum). The main color of the marking is blue.Cut profiles, pipes, fittings, etc. - For stone:

The abrasive cutting part made of silicon carbide can be of several types:- continuous - for dolomites, limestones and other soft rocks;

- segmented or turbo - for basalts, labradorites and other hard stones, as well as tiles.

The color of the marking is usually green. - continuous - for dolomites, limestones and other soft rocks;

- For wood:

Saw wheels with a cross-section of up to 2 mm, resembling circular saw blades with a diameter of up to 320 mm. Taking into account the shape of the teeth, the following types are produced:- variable beveled - universal;

- straight - for conifers and other soft species;

- trapezoidal - for wood of medium and high density.

The safest for use are universal saw blades with a cutting edge in the form of a chainsaw chain. When the cutting element jams, the circle continues to rotate, which makes it possible to quickly turn off the angle grinder with minimal risk of injury. - variable beveled - universal;

- Diamond:

Universal steel discs with a rim of the cutting part based on an alloy of nickel, tin, zinc or cobalt, in which diamond chips are embedded. The purpose of wear-resistant wheels is determined taking into account the technology of fixing tiny diamonds on the rim:- galvanizing (hard lining) - for sandstone and other relatively soft rocks;

- laser welding or sintering (soft binding) - concrete, granite and other hard materials.

Depending on the characteristics of the cutting edge, the following types of diamond wheels are distinguished:- segmented - rough cutting of concrete, stone and other high-strength materials using dry or wet methods;

- solid - high-precision cutting, including metals and stone with water cooling;

- oblique notches (turbo) - fast and precise processing of various materials using the dry method.

Depending on the type used, varieties of artificial diamonds can be monocrystalline or polycrystalline. The former are used for processing metal or stone, the latter for relatively soft materials. - galvanizing (hard lining) - for sandstone and other relatively soft rocks;

Roughing and stripping

The working part is in the form of a steel cup or two combined disks, along the edge of which twisted rollers, brushes or simply metal wire are mounted. Designed to remove rust, corrosion and various coatings - paint, varnish, polymer, dried cement, etc. Indispensable for body repairs of cars, various machines and equipment. The cross-section and strength of the wire determines the degree of processing.

There are diamond and abrasive grinding discs with working edges like grinding wheels. Used to remove plaster, concrete, stone and other high-strength finishing coatings.

Grinding and polishing

The grinder is an angle grinder, so its specialty is scraping parquet, rough and finishing processing of various surfaces, ends and edges. With this in mind, there is an extensive range of grinding and polishing discs, including:

- cord brushes - roughing for leveling or cleaning the surface;

- end abrasive attachments - specially designed for grinding the ends of parts;

- petals - special discs in the form of abrasive cloths of various grain sizes, its degree determines the quality of grinding;

- felt (fabric) wheels - ideally suited for mirror polishing, including using a special liquid or fine abrasive paste;

- fiber nozzles are a good option for processing metal surfaces;

- chain and solid-type planer wheels should be used exclusively with grinders equipped with additional handles, which allow for rough processing of logs, timber and other types of wood.

Milling

Nozzles in this category are produced in two types: circles and cutters. In the first case, the structure of the lateral working surface of the disk resembles a rasp. Used for rough processing of wood. Milling cutters differ in both size and tooth configuration. Allows you to perform the following operations:

- cutting grooves;

- selection of bowls and recesses;

- processing of edges and ends;

- cutting small-sized workpieces, etc.

Sharpening

Traditional discs, identical to those for sharpening machines. The key difference from abrasive cutting analogues is the thickness and the ability to process parts with the side part. The cross-section is at least 5 mm. In addition to sharpening tools, they can be used for removing weld seams and other types of rough metal grinding.

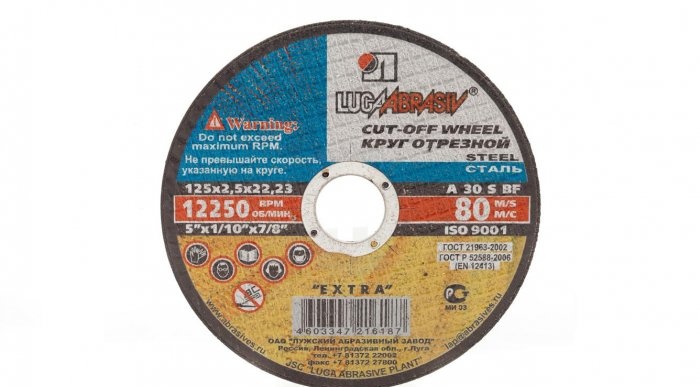

Features of marking discs for grinders

Along with the bar code of the country of manufacture and purpose, the following data is indicated on the marking of discs for an angle grinder:

- characteristics, for example, diamond, abrasive, etc.;

- dimensions: outer diameter of the cutting edge, thickness and diameter of the mounting hole in mm;

- maximum angular speed;

- maximum rotation speed;

- work angle;

- what operations are prohibited to perform;

- safety instructions in the form of pictograms;

- date of manufacture and expiration date.

Plus, you can find out other information from the manufacturer. For example, compliance with certain standards, regulatory documents in accordance with which the product is manufactured, etc.