A very useful attachment for a drill or screwdriver, made from a used grinder disc. With the help of such a device you can cut metal or process its surface. This cutting tool can be very useful for those who do not have an angle grinder (angle grinder) or are unable to use it in hard-to-reach places.

What will you need?

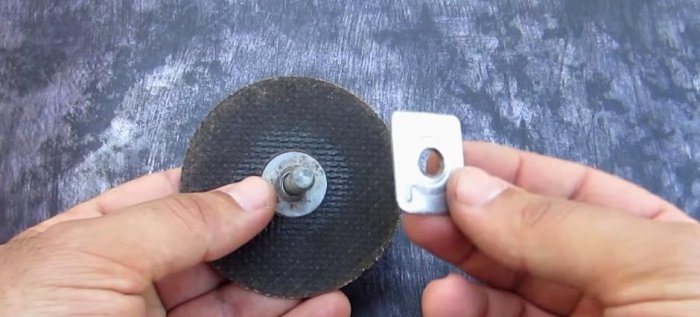

- The rest of the grinder disc.

- Bolt.

- One washer the size of the inner diameter of the hole in the grinder disk.

- Two washers with a diameter greater than the internal diameter of the hole in the grinder disk.

Making a cutting attachment

Unscrew the disk. As you can see, it should not be completely ground off. If you don’t have an angle grinder, ask your neighbor or the nearest workshop, they still throw out such discs.

Place a large washer on the bolt. It doesn't have to be rectangular. Since finding washers of large diameter is problematic, I made it from what I had on hand. The outer diameter of the washer must be larger than the disk mounting hole.

Then we put a disk on the bolt.To ensure that it stands strictly in the center, we install a washer with a diameter approximately equal to the diameter of the disk mounting hole.

We put a large washer on all this, the same as at the beginning.

Tighten everything tightly with a nut.

The result is a very useful attachment for a drill or screwdriver.

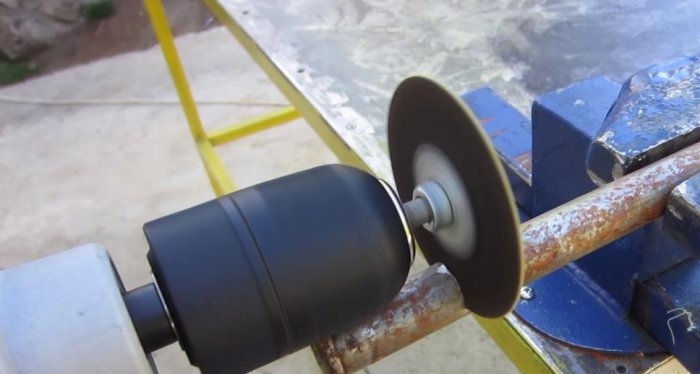

We clamp the bolt into the drill chamber.

And we saw metal. Here's an example of a steel pipe.

It cuts perfectly. There are no sparks at all, as when working with an angle grinder, since the speed of the drill is very low compared to an angle grinder.

Of course, in no case should you neglect safety precautions when working - at a minimum, you must wear safety glasses. Due to low speeds, the cutting tool has not become any less dangerous, and all protection requirements must be observed.

Using such a nozzle, you can clean the metal surface from paint or rust, cut a pipe in a hard-to-reach place, and much more. It's a useful thing, do it for yourself - you won't regret it.