A broken stud is one of the common defects that a car enthusiast may encounter. Studs are used in many parts of the car. But if you don’t have a car, this doesn’t mean you’ll never get into this situation, because a bolt can also break.

The method for removing debris that I will show, it seems to me, is one of the simplest and most effective. It will work even when the fragment is embedded 2-4 mm deep inside.

Removing the stud piece

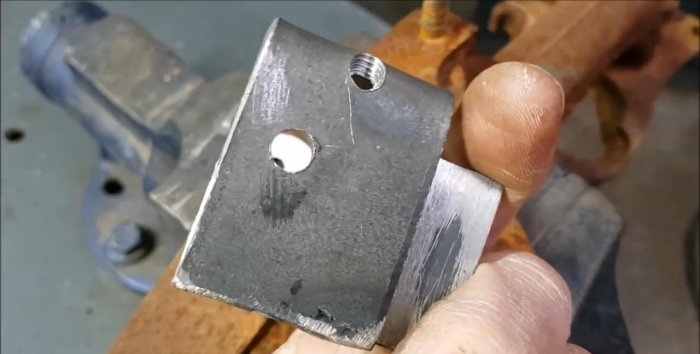

So let's get started. First, let's measure the diameter of the pin using its fragment remaining outside. In my case it is 8 mm in diameter.

Take a wooden block and stick 3 layers of masking tape on top of it. Then we make a hole in all three layers with a diameter smaller by one millimeter.

Cut out an arbitrary outline. And we got such a gasket.

We glue it onto the hole with a piece of the pin. This gasket will protect the threads during welding.

Next, you need to take any L-shaped steel corner with a thickness of 2-5 mm. And drill a hole in it 7 mm in diameter.

On the reverse side, use a large drill to make a hole for the cone.

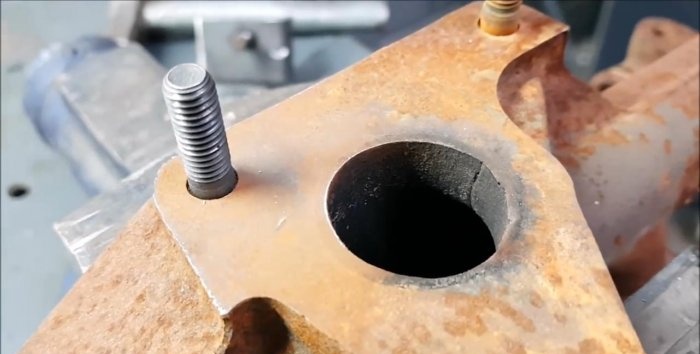

We place the corner on the hole and secure it with pieces of masking tape so that it does not fall during welding.

The holes must match exactly.

Welding time. It is advisable to use a semi-automatic welding machine. Well, if not, take a regular one, with a thin electrode.

First we fuse a layer onto the fragment.

This is what it looks like after the first time. Let's wait a little.

We fuse another layer for reliability.

Well, now you can try to unscrew the pin.

Everything worked out perfectly. The welding warmed up the fragment and it became easier to unscrew.

This is what it looks like up close.

Installing a new stud

As you can see, neither the thread nor the area around it was damaged after welding. We sand the area with sandpaper.

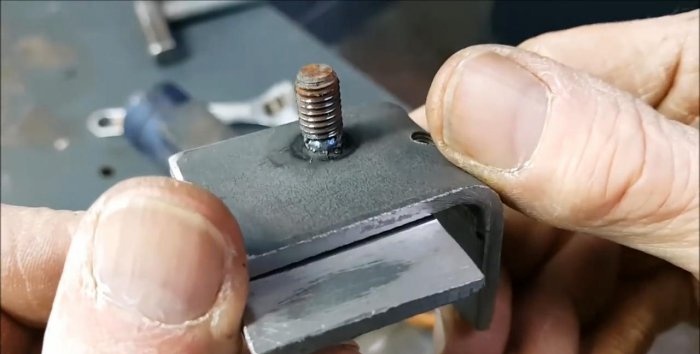

We take a new stud, screw two nuts onto it on one side and tighten them to each other.

Screw it into the block with a key.

Remove the nuts.

Here is such a simple and very effective way. At least it’s easier than drilling a straight hole for the extractor, which in my opinion is incredibly difficult.