Also, often when gluing wooden elements to each other, it becomes necessary to carefully remove excess glue from the inner corner formed by the two parts being glued, along the line of their contact. For these purposes, it is convenient to use a thin plastic tube (“straw”).

How to draw a parallel line on a piece of wood relative to a certain base if you don’t have a standard thickness planer at hand? It can be made from scrap materials very quickly and without much difficulty.The homemade product turns out no worse than a standard tool.

Sawing

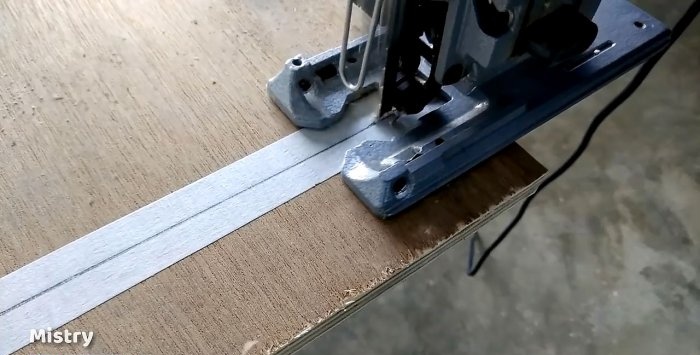

On the surface of the canvas, using a straight edge and a pencil, draw a cutting line parallel to the base of the canvas. Using an electric jigsaw, we cut the strip along the previously marked line.

The cut, as noted above, turned out to be uneven and completely unattractive. It is not possible to use such material without additional and rather labor-intensive processing.

Is it possible to saw off a strip from the main body and get a high-quality cut without additional processing? Let's try using construction tape for this purpose. We securely glue it along the entire width of the canvas and draw a cutting line along the tape.

Cut the strip from the canvas again along the line marked on the tape. What have we got now? Remove strips of tape lengthwise from both surfaces. Even by eye you can see that the quality of the cut has noticeably increased compared to the first case.

The tape consolidated and strengthened the veneer along the cut line, so it suffered less damage and is quite suitable for further use without additional processing.

Gluing

In carpentry, it is often necessary to end-glue one piece of wood or wood-like material to the surface of another. To do this, apply suitable glue to the end of the smaller part and carefully distribute it in an even layer over the entire contact surface.

Then the part with the surface with glue is installed in the place where it should be. For reliability, the parts to be glued are pressed tightly using a clamp. In this case, excess glue will be squeezed out from the inner corner along the entire line of contact.

How to remove glue easily and completely? A thin plastic tube, more often called a straw, will help us in this matter and is used when drinking various soft drinks.

To do this, you need to squeeze it with two fingers from one end to get approximately a right angle. Then, applying the deformed end of the straw to the corner with glue, and pressing it a little, draw it along the entire gluing line. As a result, excess glue will end up inside the tube.

Marking

How to mark a wooden blank for further processing when you don’t have a factory thickness planer at hand? You can get out of this situation quite easily. We take a small wooden block with parallel edges and find the center of the widest side - the face.

We mark it with the sharp end of a screw, which we will need later. Using a drill clamped in the drill chuck, we drill a blind hole with a diameter smaller than that of the screw. We screw a screw vertically into the resulting hole using a hand screwdriver.

Then, tightly pressing the edge with the screw to the base surface of the workpiece, we draw a marking line with the sharp head of the screw several times on the surface of the workpiece adjacent to the base.

Using a metal ruler, we measure the correctness of the markings. If it turns out to be inaccurate, use the same ruler to mark the updated position on the workpiece.

Then we compare the verified size with the height of the screw on our improvised surface planer. If its height is less than required, unscrew the screw; if it is greater, screw it in.

Having achieved a coincidence of the markings and the height of the screw, we again draw the line exactly as we did the first time. The resulting marking turns out to be the required one. To make sure of this, we carry out control using a metal ruler.

A few final notes

When cutting wood-like material covered with veneer, the cutting area must be thoroughly cleaned of dust and other foreign particles, and fresh tape must be used. Then the result will be better.

When removing glue, the straw must be held at a slight angle in the direction opposite to the movement.

It is better to use a hardened screw to make a homemade surface planer, and a block made of hard wood.

Materials and tools used

To implement the above operations, you must have the following materials on hand:

- veneered panel;

- construction tape;

- glued wooden parts;

- wood glue;

- a thin plastic tube (“straw”);

- a small prismatic block of wood;

- a screw with a sharp-edged head.

To achieve the three above goals, you cannot do without the following tools:

- electric jigsaw;

- metal ruler;

- pencil;

- clamps;

- hand screwdriver.