In our arsenal there is an excellent homemade product that will delight craftsmen who are more or less familiar with technology. I won’t say that this will require 5 minutes of your time and a pair of pliers with a knife, but there won’t be any higher mathematics here either. All parts are inexpensive and easily accessible. The installation itself is compact, mobile and does not even require an electrical connection!

Now let's talk about everything in order...

Tools and accessories

A two-stroke engine from a moped, scooter, or motorcycle may not necessarily be new. The author of the video assembled his own version of a motor pump using an old chainsaw engine. The engine must be equipped with a starter, carburetor, muffler, fuel tank and electric starter (button). In addition to this, we will need:

- PVC conical coupling 90*34 mm;

- Metal crimp clamps of different sizes;

- Brass flanged bushings;

- Drive shaft for models, thickness – 10 mm;

- A small sheet of aluminum, thickness – 1.5-2 mm;

- A piece of reinforced rubber hose, length 20-25 cm;

- External PVC plug, diameter – 90 mm;

- 90 degree angle PVC;

- PVC pipe, length - about 1 m;

- Threaded plastic adapter for garden hose;

- PVC plug for gluing;

- Closed bearing;

- A small piece of oxygen hose.

Tools:

- Grinder (angle grinder) with cutting disc for non-ferrous metal;

- Drill with cutting and grinding attachments;

- Screwdriver;

- Calipers;

- Protractor;

- Glue for gluing PVC joints;

- Knife, tape measure, marker.

Making a motor pump with your own hands

Insert a 90 degree angle into the cone coupling, from the side of the smaller diameter pipe, having previously coated it with glue. We leave it aside, we will need this element later.

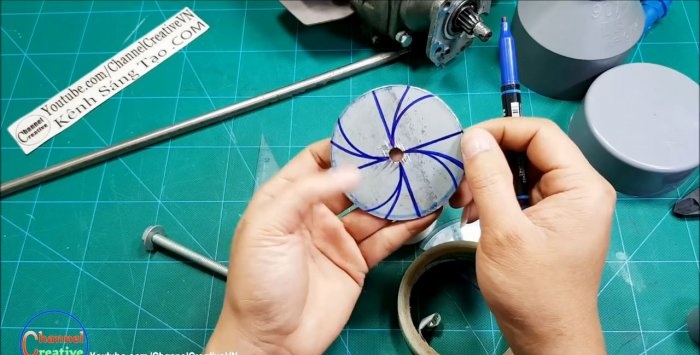

In order for water to be pumped with a pressure strong enough for irrigation, centrifugal force alone is not enough. It is necessary to make a pump impeller, which will be its impeller. We will make it from a sheet of aluminum. We mark a circle several millimeters smaller than the internal diameter of the end cap, and cut it out with an angle grinder (grinder). The end of the transfer shaft is slightly ground off and has a diameter of 8.1 mm. We make a hole for it in the future impeller with a drill.

You can trim the circle by securing a long bolt in the center and inserting it into a screwdriver. By turning it on and the grinder you get a mini sharpening machine))

Using a protractor, mark the circle into four parts. Using some round object, for example, a small solder spool, we draw out the arcs of the impeller.With this blade shape, the pump efficiency will be much higher.

From the same sheet of aluminum we cut a strip about 15 mm wide. We roughly measure the length of the blades and cut the strip into four segments. We bend them according to the shape of the drawn arcs.

We place the circle on the shaft and weld it using MMA or tungsten electrodes for aluminum, using reverse polarity (for inverters). Seams from a semi-automatic machine and wire will be much neater.

We also secure the impeller blades, distributing them according to the marks on the aluminum circle. If there is no welding, a soldering iron and special fluxes with solders may help out. We coat the finished scalded shaft with the impeller with paint, protecting it from oxidation and corrosion (automotive aerosol is best suited).

Using a 14 mm wood spade drill, we drill a hole in the PVC end cap. By putting a brass bushing in it, the welded end of the shaft will rotate freely in it while the pump is running. We fix it with PVC glue.

We will place the threaded adapter for the hose on the side wall of the end cap body. In order for the water to flow without obstacles, it must be secured at an angle. We cut the oblique thread and make a hole for it with a 15 mm feather drill in the plug. You can give it an oval shape using a knife, a round file or a drill with a grinding attachment. After adjustment, glue the adapter with glue or cold welding to the plug (the connection must be strong and airtight).

For the PVC coupling, cut off the wide ring to the collar line and the narrow ring, removing the 90-degree angle. From a short piece of pipe we make a straight adapter for the water intake pipe or hose and glue it.

Next, we drill a hole in the plug for the insert for the motor shaft.We also insert a closed type bearing into it, which we selected to match the shaft diameter.

We place the plug with the bearing on the pump body, center it using the shaft and glue it.

We cut off the excess with a hacksaw.

We make a notch on the shaft rod with a Dremel under the retaining ring; it will prevent the bearing from moving during operation.

We cut the rod with a grinder, leaving a length of approximately 100-150 mm. This size depends on the distance of the pump from the engine. For long-term uninterrupted operation of the pump, it is necessary that the shafts of the working part and the motor be at a minimum distance. Using the sealing gasket, we place the shaft with the impeller in its place in the pump housing, and put on the retaining ring.

Glue the rest of the piece - the muff cut to fit the collar. The working part of the pump is ready; it can be checked by inserting the shaft rod into the screwdriver chuck. If everything is assembled correctly, there will be no friction between the impeller and the housing walls.

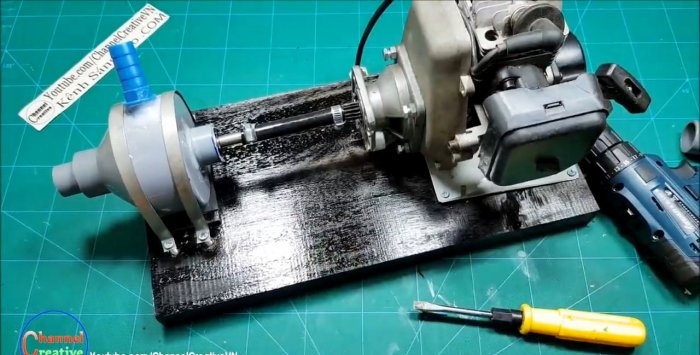

For the bed, choose a board that is wide enough. It must be stable and level so that the equipment can be positioned accurately. It wouldn’t hurt to paint it to protect it from moisture.

We position the pump on the frame so that the shafts of both working segments are in contact, and try on the mounting clamps. The shafts should be on the same line as much as possible so that the discrepancy between them does not lead to backlash, unnecessary vibration and wear of the equipment. We cut out the connecting braid for the shafts from the oxygen-reinforced hose and put on the crimp clamps.

After making sure that all connections are the right size, we secure the pump and motor to the frame with self-tapping screws. We crimp the rubber hose onto the shaft with clamps.

We attach the fuel tank to one of the sides.We attach it to a long dowel screw and connect the fuel pipes to the engine.

On the back side of the wooden frame, at the four corners, we screw shock absorbers from rubber tires folded in several layers. This way our pump will be less noisy during operation.

The start button is located outside so that it is convenient to turn on the pump by hand. We pour the fuel mixture into the tank and test run the pump dry. You can immediately adjust the fuel supply to the engine and the intensity of its operation.

Now all that remains is to connect the water intake pipe to the pump. It can be made from a regular water supply or garden hose, and connected through an adapter with a clamp. The author chose to glue an additional removable elbow from PVC pipe and fittings.

Well, let's put a container of water and check how it works?

We start the engine and set the idle speed so that the centrifugal clutch starts working. To start any centrifugal pump, you must initially pour water into the outlet pipe to remove air, and then the pump will start working on its own.

Everything functions perfectly, and under such powerful pressure!

With such an installation, you will once and for all forget what drought is like in your garden plot. Good luck to everyone and have a good harvest!