Working with an ax with such a defect becomes inconvenient and, ultimately, impossible, as well as downright dangerous. After all, a heavy metal head with a sharp cutting edge and corners flying off the handle can injure the person using the faulty ax or the people nearby.

What are the “roots” of this defect? Why does the nozzle become loose? After all, it was once made according to all the rules, very tightly, and even at the time of weakening, the wedges remained in place and did not fall out, which could be “attributed” to the defect.

The reason is that the wood gradually loses moisture, the fibers dry out and become smaller in volume. The density of the nozzle decreases and disappears completely over time.

Below we will consider the method of attaching the head of an ax to the handle in order to eliminate or at least push back the period of loosening the attachment of parts of the chopping tool into the distant future.

How to place an ax firmly on the ax handle

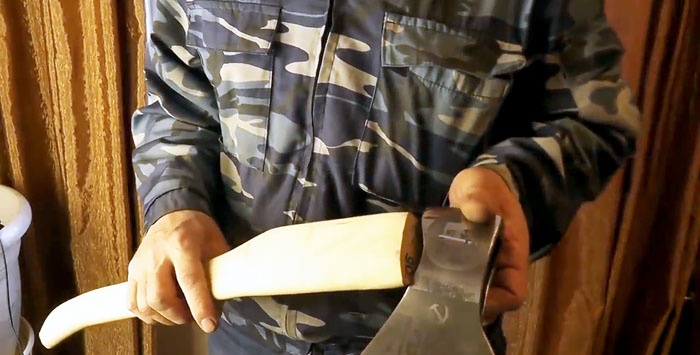

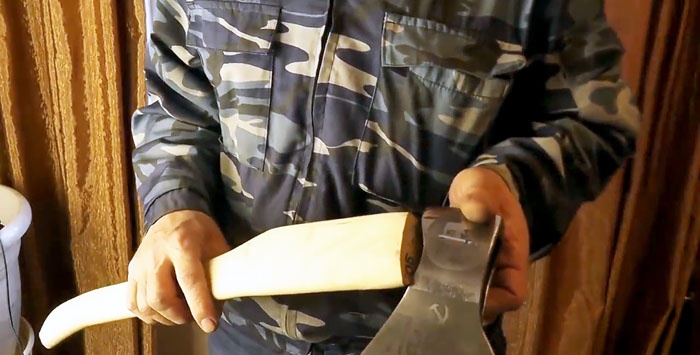

For the success of the upcoming task, it is necessary to take into account that the ax has an exit hole larger than the inlet. This is done so that after adjusting and installing the handle, it will be possible to wedge it using several wedges.

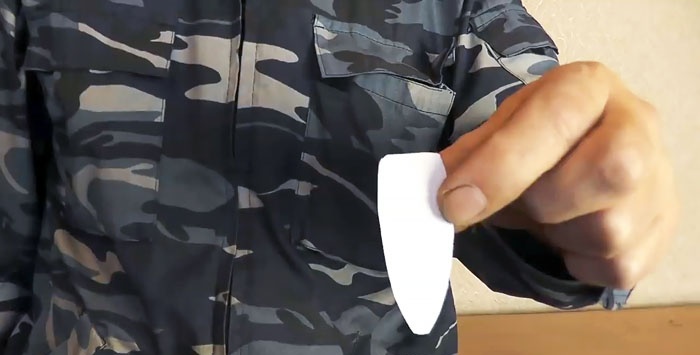

It is very important to choose the right handle for this tool. To do this, apply the eye of the ax to a sheet of paper with the output side and trace its inner perimeter with a pencil or marker.

Then, along the contour, we simply cut out the resulting figure with scissors, which in shape and size is a copy of the exit hole of our ax. It will serve as a template for us to choose an ax on the market.

To do this, we apply a paper measure to the end and select the one that matches our template as closely as possible. This approach, in addition to making the right choice, will minimize fitting work.

The selected ax must be placed on a heating radiator (in winter) or in the sun (in summer) for about 2-3 days, turning it over from time to time so that it dries completely.

After the wooden handle has completely dried, you can begin its final fitting to the axe.

To do this, we place the head on the ax handle, stepping back from its end by 5-7 mm, and draw a line on the other side with a pencil, which will indicate the boundary of how the head fits onto the handle.

We apply the previously cut paper template to the end of the handle and trace it along the contour with a pencil.

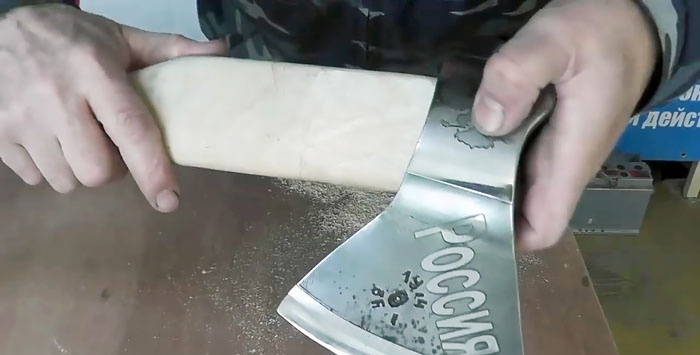

Using a large wood rasp, we process the ax handle from all sides within the nozzle area, focusing on the contour marked on the end of the handle.

After turning the handle along the contour in accordance with the template, we begin to try it on (attention!) to the exit hole of the ax head.

Carefully, so as not to loosen, we process the handle until it enters the inlet hole of the head by about 10 mm.

Using a caliper, we measure the inlet hole and fix it on our measuring device.

Then we compare the size recorded on the caliper with the corresponding size on the ax handle. We make sure that the meter on it does not fail. If we now remove the excess on the handle, we will get a reverse cone (similar to a cork in a champagne bottle).

We carry out our plans using the same rasp that we already used earlier, adjusting the end of the ax to the exit hole of the ax.

We control the wood removal by measurements so as not to weaken it. We measure the height of the outlet hole of the head and compare it with the inlet part of the axe. They should be equal to each other or the handle should be slightly smaller.

The size at the far boundary of the nozzle must be obviously smaller than at the inlet. This is the so-called reverse cone.

We control the thickness of the ax at the entrance and exit. And according to this parameter, a clear reverse taper should be felt.

We remove a small chamfer around the perimeter of the end part of the ax to ensure its initial entry into the entrance hole of the ax. To do this we use the same rasp. This operation will be considered completed if the head, after inserting the nozzle by hand, is held firmly on the handle.

We draw a longitudinal line in the center of the end of the ax with a pencil, another - perpendicular to the first and slightly above the geometric center of the cross section of the end.

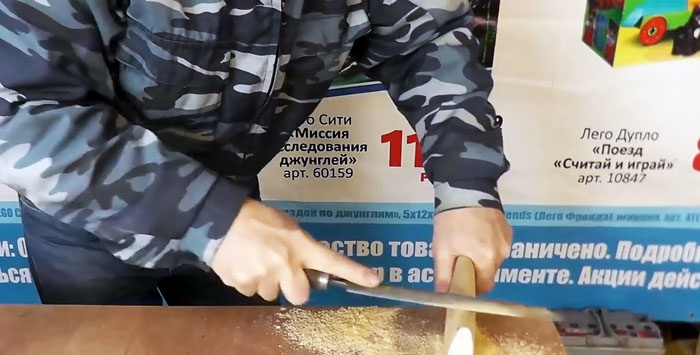

According to the markings, we make cuts for three wedges, not reaching about one centimeter to the rear border of the head attachment on the ax handle.

Once again we make sure that the handle fits freely into the outlet hole and only slightly into the opposite one.

We install the ax handle into the entrance hole of the ax head and vigorously hit the other side several times until it reaches the required position.

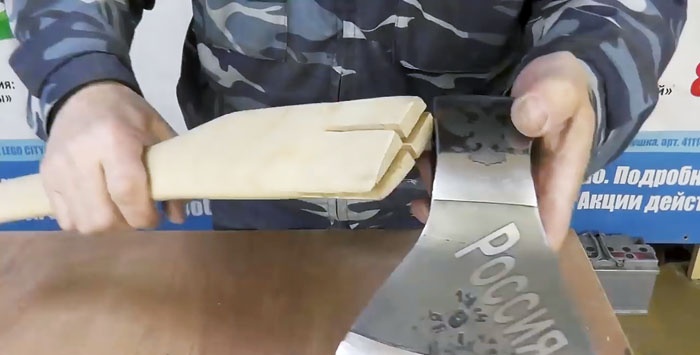

All we have to do is install pre-prepared wooden wedges on the glue. First we install a longitudinal (large) wedge, then transversely - two small ones.

To do this, lubricate their side surfaces with glue and insert them into place, lightly tapping them with a hammer.

After installing all three wedges, hammer them together with vigorous blows of the hammer as long as possible.

The ends of the wedges remaining outside can be hewed off on a grinder or simply cut off using a hacksaw.

The final finishing of the output end of the ax with wedges is carried out manually using coarse sandpaper. It can also be used to treat other parts of the handle so that it is comfortable to use and does not rub your hands.

You can leave the ax in the position that we have achieved up to this point. But then, after a short time, it will suffer the same fate as the old product that we demonstrated at the beginning: the attachment will first weaken and then disappear completely. The tool will become unusable. The reason is known: moisture from the wood fibers will evaporate, it will dry out, and the density of the nozzle will disappear.

To prevent this from happening, it is necessary to preserve the end after final installation and wedging, that is, soak it in drying oil, oil paint or glue (you can use PVA, but epoxy is better). This treatment will not allow the moisture remaining in the wood to evaporate and disrupt the density of the nozzle. If possible, it is advisable to subject the entire ax handle to this treatment.