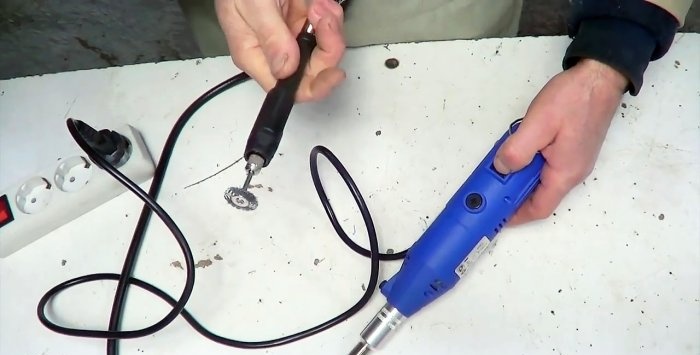

This tool with a flexible shaft, also called a mini-drill, can perform various types of processing of wooden and metal parts and assemblies in hard-to-reach places. What to do if the electric motor or Dremel drive fails? Let's try to replace it with an ordinary grinder.

We remove the flexible shaft from the failed tool and replace it with a working angle grinder. But the problem is that the angle grinder spindle does not contain a flexible shaft connection unit. Our task is to create it. What is needed for this?

Required:

- an elongated hex nut and bolt that match the threads with the spindle of the angle grinder;

- bench vice;

- working angle grinder;

- flat blade screwdriver;

- hand tap with square shank;

- hammer, pliers, pliers;

- mechanically driven emery wheel;

- metal strip 2 mm thick of the required length;

- copy pipes for making clamps;

- drill with drills;

- two sets of bolted connections;

- two plates for connecting clamps;

- welding machine;

- spanners.

Installing a flexible shaft on an angle grinder

We unscrew the union nut, which secures the flexible shaft together with the braid to the Dremel body. Use a special key to loosen the fastening of the shank on the spindle of the mini-drill and pull it out.

The main parts of the flexible shaft attachment to the new drive will be an extended hex nut and a bolt that matches its thread.

Unscrew the round nut from the spindle of the angle grinder and remove the protective casing, having first loosened the retaining clamp.

Screw the hexagonal extended nut onto the spindle of the angle grinder and screw the bolt into it until it stops.

We mark the depth of screwing on it using a marker. We clamp the bolt head in a vice and with a working angle grinder we cut the rod at the marked place and turn out the part of the rod remaining in the nut, but not all the way.

We cut the bolt rod from the end in the longitudinal direction crosswise along perpendicular diameters. Using a flat-head screwdriver, screw the rod into the nut flush with its upper plane, using the slots made.

Next, we will use a hand tap with a square shank, the dimensions of which correspond to the square of the flexible shaft shank, but not for its intended purpose, but quite the opposite.

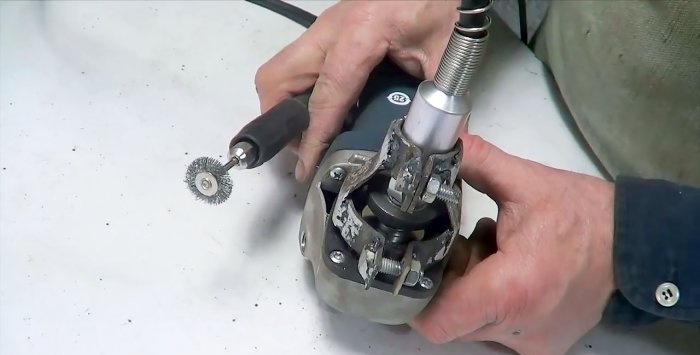

Using a hammer, we drive the tap shank into the intersection point of the slots on the bolt, then pull it out of the hole using pliers to make a socket for the flexible shaft shank. We repeat this operation as many times as necessary until the required size nest is completely formed.

Using a flat-head screwdriver, unscrew the upgraded section of the bolt shaft and set aside its side for now. Screw the extended nut tightly onto the spindle of the angle grinder and again screw the set aside part of the bolt shaft into it until it stops using a flat-head screwdriver.

We insert the shank of the flexible shaft into the slot of the bolt rod and make sure that it “sits” there tightly without any noticeable gap. We slide the union nut on and mark the amount of turning along the diameter and height of the extended nut.

We unscrew the nut from the spindle of the angle grinder, unscrew the bolt rod with cross-shaped slots from it, and instead of it, screw in the bolts on both sides, by which we will hold this hardware while processing it.

Grinding in accordance with the markings is carried out on an emery wheel with a mechanical drive. We make sure that after turning the union nut of the flexible shaft slides freely onto the ground part of the hardware and does not reach the unprocessed belt.

Screw the modified nut onto the spindle of the angle grinder. Using a flat screwdriver, screw the flexible shaft shank holder into it all the way and again try on the shank and union nut to see if they “fit” in place.

Now it is necessary to firmly and without displacement fix the union nut of the flexible shaft (which, in fact, turned out to be “hanging” in the air) in relation to the base of the angle grinder spindle. This can be done using a rigid frame of two clamps of appropriate diameters and jumpers between them, connected to each other using electric welding.

Using a caliper, a metal ruler and a marker, mark on an old metal strip of suitable length the required width sufficient for making clamps.

We clamp the marked strip in a bench vice to cut it along the marked line with a working grinder.

We grind a strip of the required width on a mechanically driven emery wheel to remove burrs and complete the intended assembly as accurately as possible.

Using a caliper, we measure the diameter of the base of the angle grinder spindle and select a piece of pipe of the same size, which will serve as a template for making the appropriate clamp.

We clamp one end of the strip vertically and the pipe horizontally in a bench vice and, hitting the strip with a hammer, bend it around the pipe.

We try on the resulting ring to the base of the angle grinder spindle and mark the bending points and sections, taking into account the length of the “ears” for the tie bolts.

We again clamp the strip in a vice and cut along the markings. Next, we form the “ears” and straighten the bandage with a hammer to give it a cylindrical shape. To be safe, we once again try on the almost finished bandage with ears to the base of the angle grinder spindle and make sure that it corresponds to the intended place.

We select a template pipe to make a part for the girth of the union nut of the flexible shaft and, in the same way as in the previous case, we form it using hand strength, a hammer, a vice, a marker, a working angle grinder and pliers.

We make sure that the clamp is suitable in size and shape for the corresponding part of the flexible shaft, and then we mark a place for drilling holes for the coupling bolt.

We install the finished clamps in their places, as well as the shank of the flexible shaft. Tighten the coupling bolts on the clamps until they are completely immobilized.

We apply a metal strip to them, marking the places of bending and cutting. Using a working angle grinder, cut two pieces of the required length.

Then we bend them in accordance with the diameters of the connected bandages and carry out the final fitting, applying the already curved strips to the clamps and marking the welding points.

First, according to the marks, we weld the strips to the bandage of a larger diameter from the outer sides opposite each other and symmetrically relative to the “ears”.

Then we clamp a smaller diameter clamp in a vice between the two free ends of the strips and also connect them using welds.

After completing the welding work, we process the seams on a mechanically driven emery wheel, on the one hand, for safe work in the future, and on the other, to add aesthetics to the product.

All that remains is to install our frame in its place, first securely fastening the clamp to the base of the angle grinder spindle by tightening the coupling bolt with wrenches.

Then, in the cross-shaped cut of the threaded insert, we install the shank of the flexible shaft, slide the union nut on and, finally, using keys, firmly tighten the clamp on the union hardware.

Result

Once again, having made sure that the clamps are firmly and securely fastened in their places, we turn on the grinder drive and see how the working element at the end of the flexible shaft begins to rotate. Our work has been successfully completed.

The resulting tool can now be used for processing both wooden and metal blanks and parts.