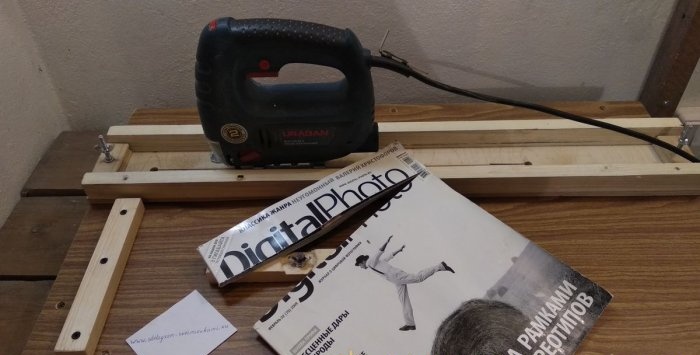

Making an even, straight cut with a budget jigsaw is not at all easy. The reasons are simple - backlash in the jigsaw, the file slipping, little experience of the craftsman. All these reasons can be easily eliminated with the help of a homemade frame with guides for the base of the jigsaw.

The presented design allows you to cut wood, sheet metal, plastic and even paper at an angle of 30, 45 or 90 degrees. Purely for the sake of experiment, I cut up an old magazine and, as you can see in the photo, the cut comes out almost like it came from a printing house.

Required materials and tools:

- Sheet of fiberboard or plywood 400 x 700 mm;

- Slats 30 x 50 and 20 x 30 mm;

- Self-tapping screws;

- M6 studs;

- Wing nuts M6;

- Furniture fittings (screw nuts) M6;

- Tools: jigsaw, screwdriver/drill, square.

Step-by-step instructions for making jigsaw guides

1. As a base for the village, I took a door made of DPV from an old cabinet. You can use a sheet of plywood.On the base we mark the centers of future supporting elements made of wooden slats - the distance from the edge should be equal to half the thickness, in my case 15 mm with a slatted thickness of 30 mm.

2. Along the perimeter we make holes for screws with a diameter of 3 mm with chamfers so that the heads of the screws do not protrude above the plane of the base of the frame. There are 2-3 holes on each side.

3. The next step is to use wood screws to fasten the base supports from 30x50 mm slats one by one. Supports are necessary so that there is free space for the jigsaw file.

Finished base from the reverse side.

And from the working side.

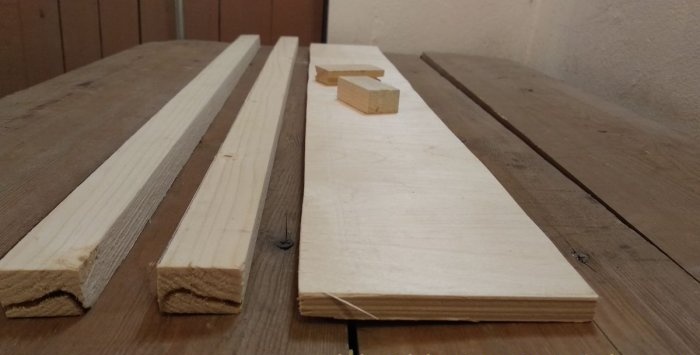

4. Next, we make guides from two 20x30 mm slats and a base from 10 mm plywood, as well as jigsaw travel limiters from a slats of the same section.

The length of the guides must correspond to the length of the bed, and the width is selected individually for each jigsaw. Looking ahead, I will present a photo from which the principle of selecting the width of a plywood base is clearly visible.

5. First you need to dismantle the base of the jigsaw. Next, applying a 20x30 mm strip, we make markings for fastening with self-tapping screws.

6. Place the batten under the sheet of plywood, with the markings remaining on top!

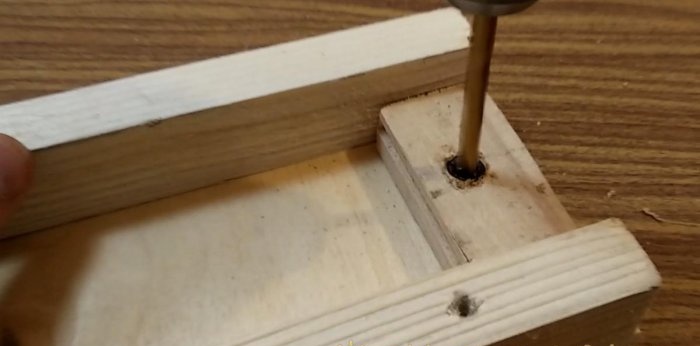

We make three holes for self-tapping screws with chamfers to “hide” the fastener heads.

We attach the rail to the base of the guide.

7. We attach the second side rail only after trying on the base - it should move freely between the slats, but without play. After “trying on” the slats, we temporarily fasten it on top with two self-tapping screws, and then, by analogy with the sixth step, we fix the second slatting and unscrew the temporary screws.

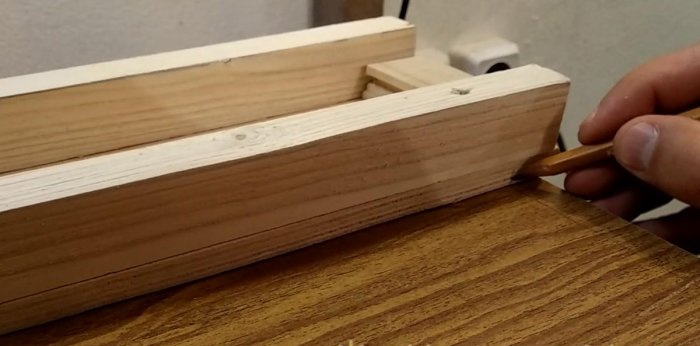

8. We secure the travel limiters with two self-tapping screws.

9. Based on the completed markings, in the first step we make marks with a pencil along the edges of the guide.

Using the marks, we mark and make holes with a diameter of 6 mm.

10. Using the holes made in the previous step as a jig, we make holes in the base.

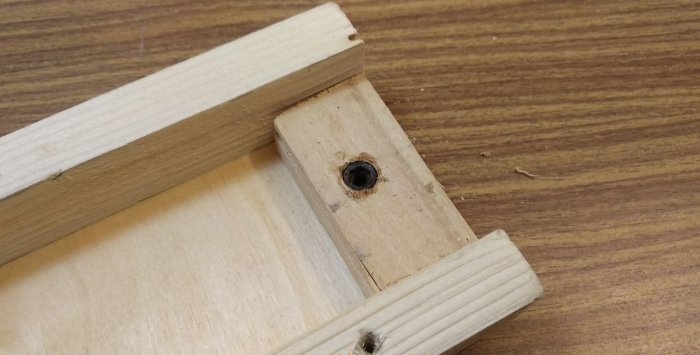

11. Use a 10 mm drill to make blind holes 10 mm deep.

12. Screw furniture fittings into the resulting holes using a hexagon. They can be purchased at hardware stores. furniture.

We screw M6 studs into the footings.

13. We perform similar operations on the guide.

Then we drill out the internal thread of the fitting with a 6 mm drill.

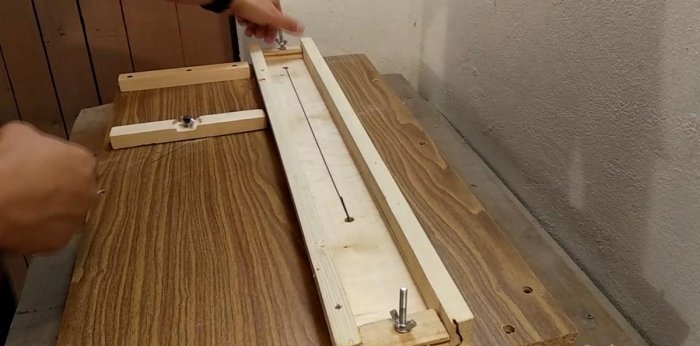

14. Mount the guide on the studs.

The movement should be free, without jamming.

15. Using the markings, we make a through hole for the jigsaw file (don’t forget to take into account the protruding pin).

16. We carry out a longitudinal cut with a jigsaw; at this step it is important not to rush, performing the cut at low speed with the pendulum mode turned off (mark “0”) in order to get the most even cut without moving the file.

17. Using a square, we attach a stop from a 20x30 mm rail perpendicular to the guide.

It will be used for right angle cutting.

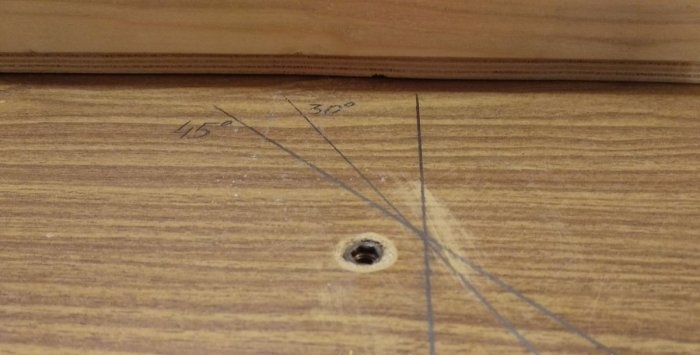

18. For cutting at an arbitrary angle (30, 45 degrees), we install a second stop, using furniture linings and a screw. I made the screw by tightly screwing a wing nut onto an M6 bolt.

19. Using a protractor, mark the angles necessary for your needs.

20. To securely press the parts, install wing nuts.

The jigsaw bed is ready.

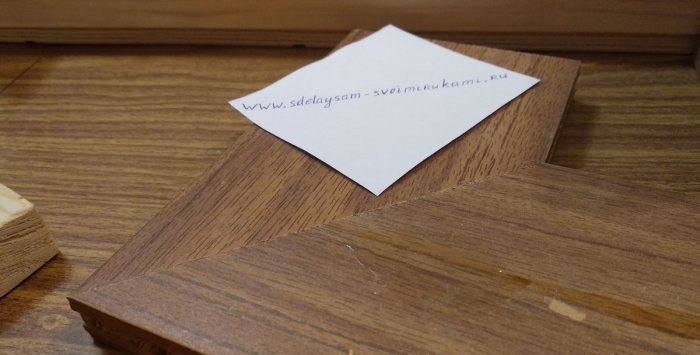

Examples of cuts can be seen in the photo below.

As you can see, the cut is clean and even. Without such a device, even with extensive work experience, it is difficult to obtain a cut of such quality on a budget jigsaw.

The bed in operation and step-by-step instructions for making it yourself can be seen in the video.