Welding with preliminary hole preparation

To gain the necessary experience, a novice welder should start making electric rivets by first drilling a hole in the top sheet metal. When welding steel 3 mm thick, its diameter should be 6-9 mm.

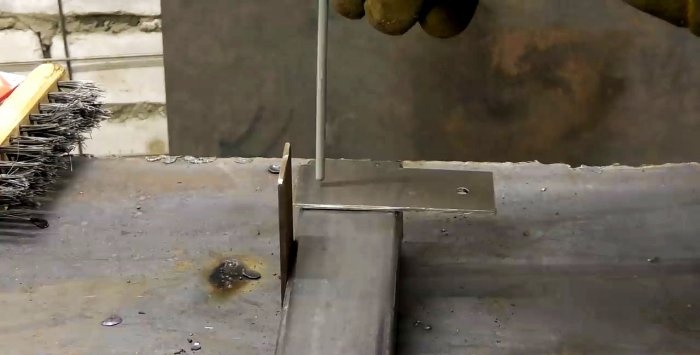

The electrode is applied to the bottom workpiece through a hole in the top sheet. If thin steel is used, then it should start igniting from the center, then slowly move and continue fusing the metal at the edge, moving upward in a circle. On thick metal with a large hole, you need to ignite the electrode at the edge, and when moving in a circle, sometimes move towards the center.

To get a reliable rivet, you need to follow several rules:

- To quickly heat up the lower workpiece, it is better to set the current to 110A on the welding machine.

- Place at least 2 rivets to prevent the parts being connected from being twisted out.

- Press thin workpieces tightly together to prevent burning of the top metal;

- The higher the cross-section of the metal, the larger the diameter of the hole for installing the rivet is needed.

- The rivet is installed in one go without pause. Thanks to this, all the slag will collect on top and it can be knocked down, creating a neat fungus.

Installing an electric rivet by burning without a hole

Having some experience in seam welding, you can immediately try installing electric rivets without drilling the top sheet. This method is suitable for spot welding thin sheets. The electrode is placed at the junction and held until the characteristic sound of burning the upper part appears. As soon as the sheet burns out, you need to slowly raise the electrode, fusing the metal, to close the resulting hole.

When placing electric rivets on thin metal, you can use rutile electrodes. On more serious workpieces, a base coating is better. If at least 2 rivets are made, then the connected parts will be impossible to break in any direction of impact. Cooking with rivets is faster and more economical in terms of electrode consumption, so the method is really useful.