Necessary materials:

- dense foam or polystyrene foam;

- hot glue;

- plaster or alabaster;

- aluminum for casting;

- sand with clay.

Handle ebb

The first step is to release the shank. We remove the remaining wood and cut off the rivets.

We knock out or drill out their remains.

The blade is very rusty, it is better to clean it before casting. This can be done mechanically or using electrolysis.

Since the new handle will be poured on top of it, several holes must be made in it for grip, but not too large, so as not to reduce strength.

You need to cut a handle of the required shape from two halves of dense foam.

Since it will be cast from aluminum, a casting channel will be required.To do this, it is necessary to leave a long outlet on the foam plastic, into which the molten metal will be poured. To increase the chances of making the casting the first time, it is better to prepare two grooves for the sprue in front and in the head of the handle.

The foam form must be glued to the shank using hot glue.

The top is covered with plaster or alabaster. To do this, the composition is diluted quite thinly and coated with a brush.

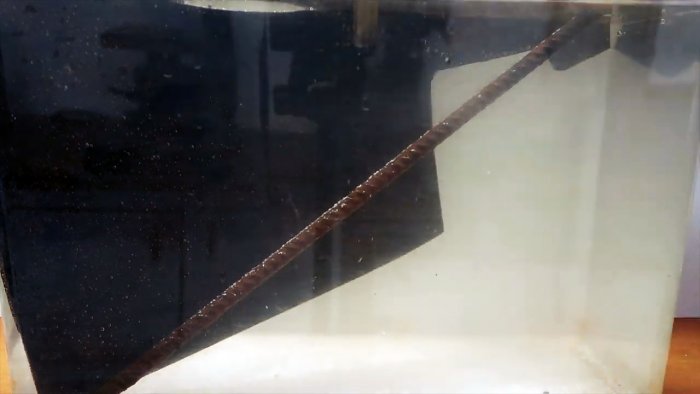

The dried handle is placed in any container and covered with sand mixed with clay for density. If there is not enough sand to cover the sprue, you can place a piece of pipe or tin can on top to create a superstructure.

Aluminum is melted in a crucible.

After turning into a liquid state, it is necessary to remove the film that has accumulated on top. It is grabbed with a metal spoon or ladle.

As soon as there is no film left on top, the metal can be poured into the sprue. It will begin to melt the foam, taking its place. In this case, the sand will not fall out, since it is held in place by a gypsum shell. It is quite possible that it will not be possible to calculate the required amount of metal and pour it all out accurately the first time. In this case, after hardening, the defective handle will have to be cut off and the process repeated again.

Having achieved complete filling of the foam area with aluminum, the sprues and unnecessary deposits are cut off from the handle.

Next, a file is used to give it the required shape of the handle.

Then smoothing is done with fine sandpaper.

It is also advisable to polish it using a wheel or manually.

The result is excellent.