Silicone seals and gaskets, like rubber ones, can withstand pressure up to 10 bar, but in terms of temperature they are more “hardy” and operate steadily in the range from -50 to 280 degrees Celsius, while for rubber products it is limited to 100 degrees Celsius. Also, silicone is much more elastic than rubber and therefore more versatile in use.

It is not difficult to make silicone gaskets yourself and you do not need to have any special skills or purchase expensive materials.

Will need

To make silicone gaskets for use in the household or in auto repair, we will need the following materials, tools and accessories:

- aluminum mold;

- silicone cartridge;

- cartridge gun;

- metal spatulas;

- container with a lid for boiling water.

Process of manufacturing and accelerated polymerization of silicone gasket

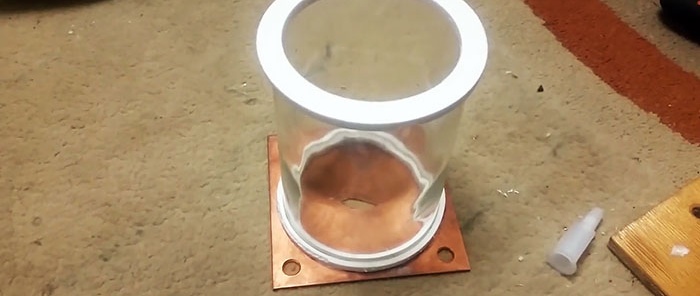

If you have a lathe, you can turn an aluminum mold for the silicone gasket yourself or order it from a turner.The product can be given any profile: flat, round, with a circular groove, etc.

Place the mold on a horizontal surface and use a gun to fill the groove for the gasket. You must try to fill the mold profile from the bottom so that there are no air bubbles left in it.

When filling a mold with silicone, you must follow the rule: more is better than less. Excess can always be removed without problems.

Now, using a narrow metal spatula, press and level the silicone mass into the recess of the mold. Remove excess silicone using a second spatula.

Of course, you can leave the mold with silicone in the open air and even put it in a warm place, but in this case, polymerization of the silicone mass and its transformation into a full-fledged gasket will take at least 36 hours.

The process can be significantly accelerated if the mold with silicone is placed in a pan of water, brought to a boil, closed with a lid and kept in such a humid environment for about 12 hours.

Under the influence of steam and water, the polymerization process will occur quickly throughout the entire cross-section, and the gasket will acquire the necessary homogeneity, strength and elasticity. In this case, the initially transparent mass will acquire a matte color. Now the gasket can be used for its intended purpose without restrictions.