Materials:

- steel round timber 50 mm;

- bearing with an inner race diameter of 40-45 mm;

- round blank for grooving the pulley;

- steel strip (it is optimal that its thickness is equal to the width of the bearing);

- extended nut M14;

- M14 bolts – 3 pcs.

- nut M14;

- cable 4 mm or thicker;

- thick-walled pipe 20 mm;

- sheet steel 5-10 mm;

- high-speed steel blank for making a disk.

Making scissors

The working shaft of the scissors is turned on a lathe from 50 mm round timber. There is a groove on it on both sides. One for the diameter of the bearing, the other for the pulley.

The pulley itself is also made on a lathe from a massive blank. This is the power part of the machine, so it must be durable.

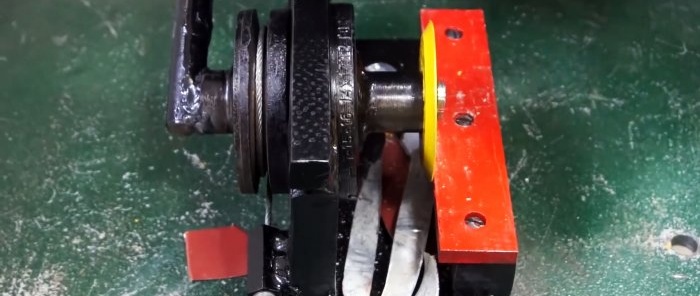

A frame is welded from a steel strip. Its internal height should be 1-2 mm greater than the outer diameter of the bearing. The width is approximately 2 bearing diameters.

A shaft with a bearing and a pulley is inserted into the frame. Then a disk of the same diameter is put on and welded onto the edge opposite the pulley. As a result, the structure rolls in the frame, like a wheel on a rail.

A loop of cable is wound around the pulley. The ends of the cable are fixed to the frame. One is threaded through a bolt drilled across. This, in turn, is screwed into the frame, thereby clamping the cable. The second end of the cable is passed through an elongated nut welded to the frame, then through a bolt drilled along the length and screwed into it. The exposed edge is crimped. A second bolt is welded near the bolt with the transverse hole. This fastening allows you to adjust the cable tension at both ends.

On the pulley side, a lever made of a thick-walled pipe is welded onto the shaft. The frame is then welded onto the sheet steel base.

2 holes are made at the end of the shaft on the opposite side of the lever. They are threaded. Then a disk machined from high-speed steel is screwed to it with two bolts. This fastening will allow it to be removed for sharpening in the upward direction without dismantling the lower stop.

Then you need to make a lower support for laying the cut pieces. It should be slightly higher than the edge of the cutting disc. The emphasis can be gained by folding a strip or other available rolled metal into several layers. The bottom strip is welded to the sole, and the top strips are screwed to it.

The finished machine can be painted if desired. Before use, you need to lubricate the bearing and tighten the cable well. As the edge of the disk becomes dull, its fastening can be released and the sharp side turned towards the cutting area.