What you will need:

- channel;

- profile and regular pipes of different diameters;

- Sheet steel;

- extended and regular M10 nuts;

- M10 bolts.

- M10 pin;

- corners of different sizes.

Manufacturing process of grinding machine

For the machine bed, you will need to cut a piece 40 cm long from the channel.

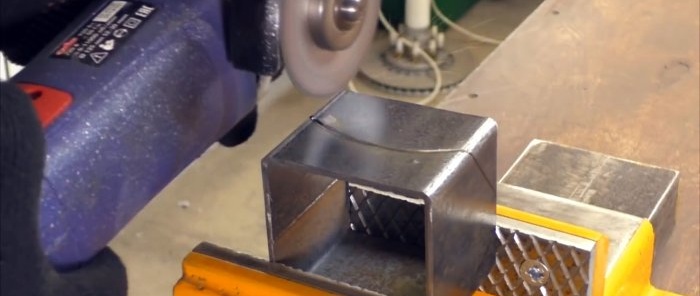

Then you need to make 2 mounts for grinders. To do this, you can use a large profile pipe. 2 pieces of approximately 6-8 cm wide are cut from it, and the walls are cut off as in the photo.

One fastening blank must be plugged from the flat end with a plate and smaller sections of profile pipe must be welded to it in order to lift it. The second fastening is made in a similar way, but sections of a profile pipe with two elongated nuts welded between them are welded to it from below.

The fastening without nuts is welded to the edge of the frame. Opposite it, with a slight indentation, it is necessary to cut a groove along the width of the nuts and insert the second fastener into it. Having turned the frame over, you need to sharpen the nuts if they stick out, and put bolts in them through the plate so that the second fastener slides.

A smaller plate is welded on top between the bolts, and an elongated nut is welded onto it. Then you need to weld the end of the frame on the side of the sliding fastening. A hole is drilled in the resulting sidewall opposite the nut and a long pin is inserted into it. It is screwed into a nut, and a knob is welded to it. Now, when you rotate it, you can change the gap between the fasteners.

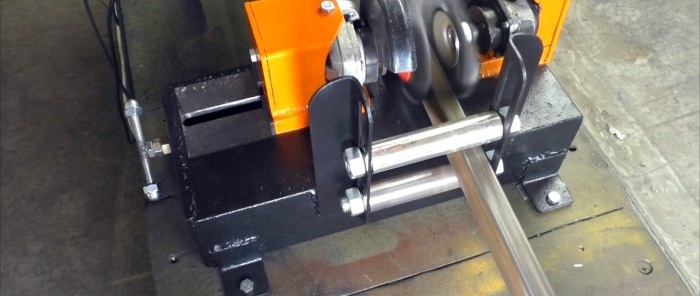

In the center, on both sides of the frame, with a gap of 12-15 cm between them, racks are welded from the corner for fastening the rollers. Grooves are pre-cut into them for adjustment.

Next, 3 rollers are made. They consist of pins with two tubes of different diameters placed on top. The assembled rollers are clamped to the stands with nuts. One thrust roller is installed on one side, and two guides on the other. You also need to weld fasteners to fix the frame to the table.

Then you need to drill holes in the holders for installing grinders and paint the machine. The rubbing parts of the device are lubricated with oil, nuts are screwed onto the adjusting pin and washers are placed to fix it in one position.

Before use, the frame is screwed to the table. The machine is equipped with 2 grinders with metal brushes. They are clamped with bolts through the standard holes for the handles. The distance between the equipment is adjusted to the width of the pipes being stripped. Next, the angle grinders are started, and a pipe is fed between them.By running it back and forth a couple of times, you can completely remove the rust.