In order not to buy expensive aluminum blanks for turning, they can be cast at home from unnecessary scrap. To do this, you need to make a box for the sand mold and a model of the blank.

What you will need:

- wooden lining;

- glazing beads;

- sheet steel or strip;

- sand;

- clay.

Preparation and casting process

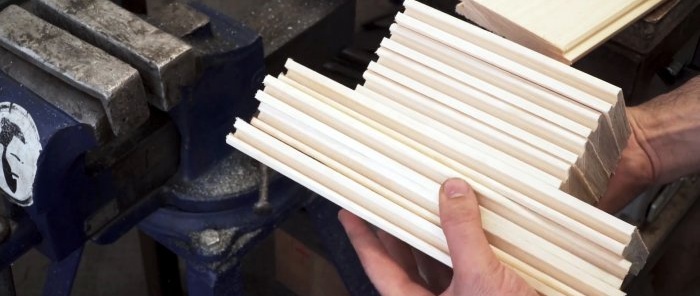

The first step is to assemble a two-piece collapsible casting box. The easiest way is to put it together from clapboard or floorboard with tongues and grooves. First, the lower wide frame is made, then the upper narrow one. It is important that the grooves at the top coincide with the tenons at the bottom. To prevent the sand-clay mold from falling out of the boxes, you should make hooks by nailing glazing beads from the inside.

Next, 2 plates with holes are prepared and screwed along the frame connection line. Then the sides of the box are marked with paint so that in the future the halves always fit together correctly the first time.

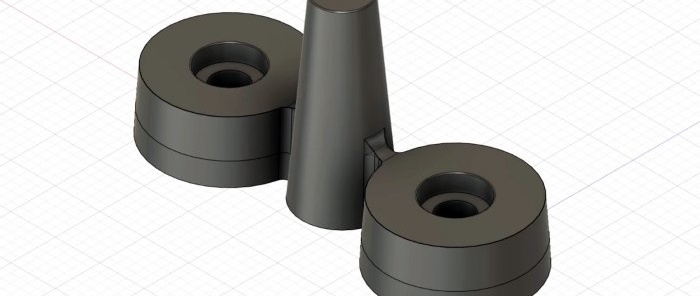

Once the boxes are assembled, two-piece casting models can be made. It is most convenient to print them on a 3D printer, but they can be machined from dense foam, wood or plastic.If you plan to cast several blanks at the same time, then the models are combined with a common sprue.

Models are sprinkled with talcum powder. Then their lower half is placed in a wide frame of the box, covered with a sifted mixture of sand and clay, and compacted tightly.

The mold is flipped over and the other half is docked to the model. Then the narrow frame is joined to the wide frame. The dense surface of the sand mold is sprinkled with talc. Next, the mold is filled to the top with a mixture of clay and sand and compacted.

After compacting, you need to unscrew the connecting plates between the frames. Then the top drawer is removed. Next, you need to tap the models with a wooden mallet and remove them from the lower mold.

After this, you need to push the sprue into the lower mold through the tube. On the reverse it expands to provide a convenient filling funnel.

The molds are blown away from the fallen grains of sand, and I am going back without the model. If sand and clay were moistened for better compaction, you should wait for them to dry, since molten metal cannot be poured into a wet mold.

Aluminum is melted in a forge, muffle furnace, or simply over coals. The floating slag is removed as efficiently as possible to avoid pores after the metal hardens. Next, liquid aluminum is poured into the sprue.

After cooling, the mold is broken, the workpiece is removed, the excess is cut off, and the blank for turning is ready.