A good vice is 10 times more profitable to make than to buy. If you have an old screw jack and scraps of plywood, it will cost virtually nothing. A homemade vice made from a jack screw will be much more reliable than analogues made from a threaded rod.

Basic materials:

- round steel bar 14 mm;

- plywood 18 mm;

- laminated plywood 6 mm, 12 mm, 18 mm;

- screw jack

Vise manufacturing process

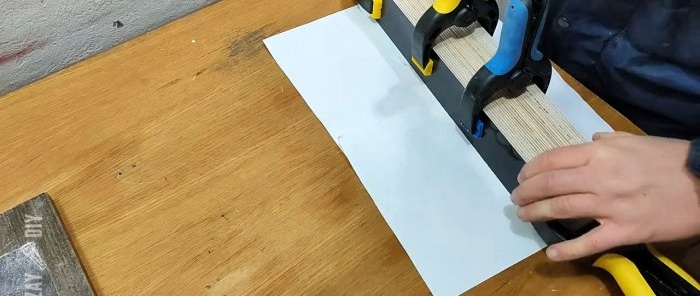

It is necessary to disassemble the jack and remove its screw, nut and one threaded cylinder. Next you need to start making the guide strip. To do this, 4 blanks of 60x350 mm are cut from 18 mm laminated plywood. A block is glued from them. It is important that the laminated layer faces outwards.

Blanks are cut from ordinary 18 mm plywood to make the base and jaws of the vice. You will need 2 parts measuring 200x180 mm, and 5 parts measuring 120x200 mm. Of these, you need to glue 3 blanks, connecting together 2 parts 200x180 mm, 2 - 120x200 mm, and 3 - 120x200 mm.

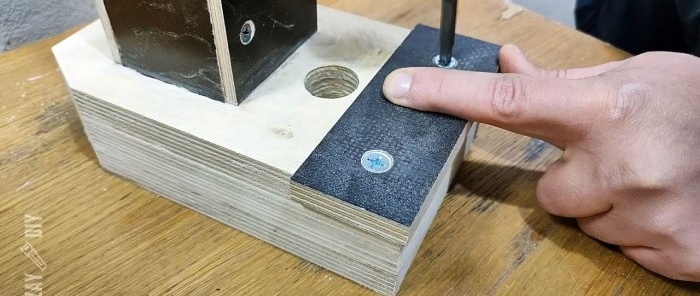

After drying, on the last two blanks you need to mark a square hole for the guide bar. It should be shifted to one side.A through hole is drilled a little above it for the screw removed from the jack.

Next you need to make a square hole for the bar. On a three-layer part, you need to drill 2 layers. This will be a movable sponge. A two-layer workpiece must be drilled through.

On both jaw blanks, select a quarter above the hole for the screw in order to install the pads there in the future. The depth of the quarters is 10 mm. Then the corners of both parts are cut off on the side of the square holes.

Next, you need to drill the blank of the vise sole in the corners. Also, 2 blind holes are made on selected quarters for installing overlays. Dowels are glued into them, into which furniture nuts are then screwed. On a fixed three-layer vise jaw, you need to widen the hole for the screw to the depth of two layers.

Next, you need to clean out the holes for the guide bar with a chisel. Furniture nuts cut into the dowels. Then you should glue the guide bar into the movable three-layer jaw, and additionally screw it on from the end with self-tapping screws.

2 overlays made of thin 6 mm laminated plywood measuring 314x72 mm are glued to the side of the plank. You also need to drill a fixed jaw on the side opposite the hole for the screw in order to insert a threaded cylinder into it for screwing it in.

The fixed jaw is installed on the guide rail. Then the base of the vice is glued to it. The rail is lined with paper on all sides to create a gap. On the side of it there are 2 side panels made of 18 mm laminated plywood. Their length is 200 mm, height on one side is 106 mm, on the other 144 mm. Between them lays a part 72x200 mm. The sides are fastened with glue and self-tapping screws. The paper is then removed.

Covers made of 12 mm laminated plywood are screwed onto the selected quarter of the jaws. Next you should work on the vice crank. For it, you will need to cut 4 disks with a diameter of 90 mm with a plywood crown, which will need to be glued into a head.

A hole is cut into the first two disks for the screw nut. It is necessary to provide for the possibility of locking it on the thread with a pin. A nut is installed in the first disks, and after screwing in the screw, it is fixed with a pin. Next, the remaining disks are glued. The head is then drilled from the side.

The discs are secured with self-tapping screws, and a handle made of 14 mm steel round timber is inserted through the side hole. To prevent it from falling out, stoppers are glued to its ends.

The vice is screwed to the table and soaked in oil. For better fixation of workpieces with a round profile in them, a cut can be made in the center of the linings. As a result, we get a very decent tool at a low price.