The ideas for turning projects are truly endless. It would seem that you can’t come up with anything new, but turners never cease to amaze. This idea is to make a ten-start thread, the nuts on which can be screwed in any direction.

What you will need:

- lathe;

- router with adapter;

- tungsten carbide cutter with a sharpening angle of 60°;

- duralumin blanks.

Ten-start thread manufacturing process

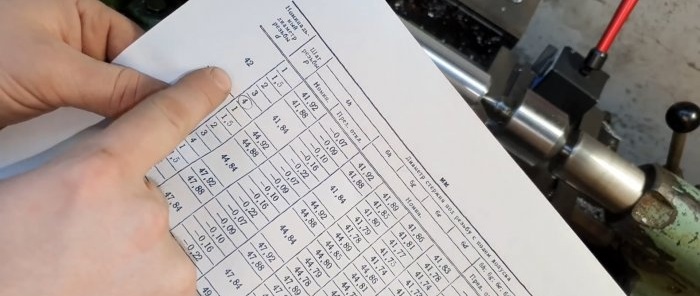

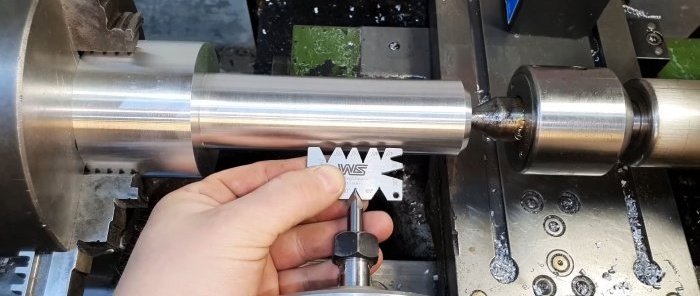

For this job, you need to make a mandrel for the router to clamp it in the lathe instead of the cutter. Before installing it, you will need to grind the rod. You can determine its size and thread pitch using the GOST 19258-73 table. In the example, M42 thread with a pitch of 4 mm is selected.

Since the thread is ten-start, a pitch of 4 mm is required multiplied by the number of starts. That is, the machine is adjusted to a pitch of 40 mm. Before starting work, you should make sure that the cutter approaches the workpiece at a right angle. The cross feed dial is set to “0” at the moment the cutter touches the blank.

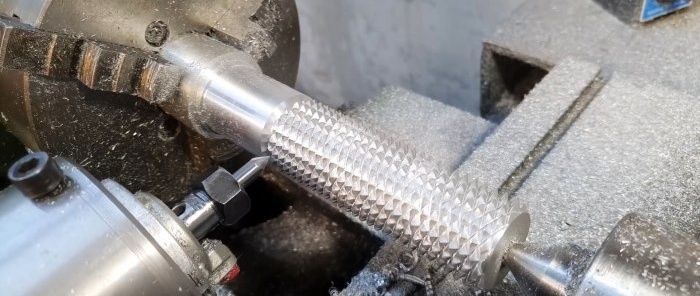

The first step is to grind the workpiece at the end of the thread to obtain a groove for the cutter to exit.

This is already done with a milling cutter. The lathe spindle must be set to minimum speed.Even if this is too fast, you will have to use a frequency converter.

The thread cuts to a depth of 3 mm. Depending on the power of the router, milling should be divided into 3-4 passes. Having prepared one pass, you need to move 4 mm to cut the next turn, etc.

After cutting a right-hand thread, you need to switch the machine to the left-hand cutting mode. Then everything is done in the same way, but in the opposite direction. The blank itself can be styled as a bolt by forming a hexagonal head at its end.

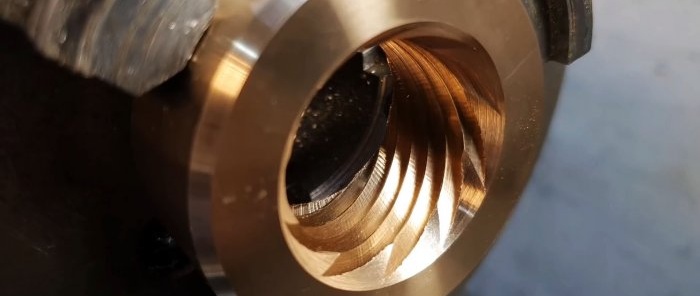

Finally, 2 ten-thread nuts are cut.

One with a left-hand thread, the other with a right-hand thread. As a result, we get a very interesting souvenir.

Watch the video

Oleg Pevtsov on his YouTube channel shows how this can be done on a lathe with your own hands.