To drill various surfaces at right angles with a drill, a drill stand is required. It allows you to direct the drill strictly perpendicularly, eliminating its distortion. You can make such equipment for a drill from scrap materials.

What you will need:

- Pipe 40-50 mm;

- nuts M6, M8;

- wing bolts M6, M8;

- profile pipes 15x15 mm, 20x20 mm, 40x40 mm;

- channel 50x50x5 mm;

- sheet steel 3-4 mm.

Rack manufacturing process

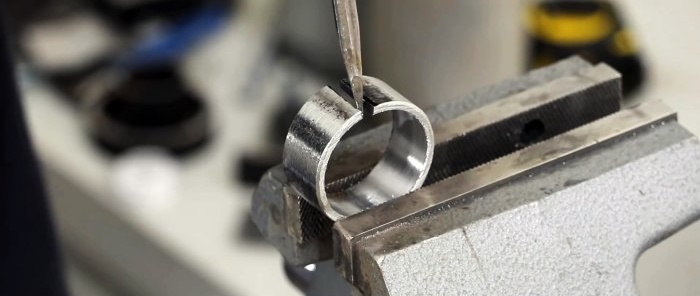

From a pipe with a diameter of 40-50 mm it is necessary to cut a ring 20 mm wide.

It is cut lengthwise and nuts are welded to its edges.

The result is a clamp for clamping the drill body. He will clamp it in place of the removable standard handle. A thread should be drilled in one of its nuts.

The clamp is welded through a spacer made of a plate to a section of 20x20 mm profile pipe. The latter must be ground off the internal weld seam.

Next, you need to weld the L-shaped stand itself. Its sole is made of a 40x40 mm profile pipe with a length of 100 mm. The ends of the latter must be welded with plugs.

A piece of 15x15 mm pipe, 300 mm long, is welded to the edge of the sole at a right angle.The open end of the stand is also welded with a plug.

On the stand you need to mark the scale using a ruler. To do this, marks are first placed, and then cuts are made along them.

From a 20x20 mm pipe it is necessary to make stops for the sliding mount of the drill. To do this, 2 narrow rings are cut out.

They are drilled from the side and M6 nuts are welded into them.

The limiters will fix the lower position of the drill mount, and the upper position so that it is not removed. They will be clamped using wing bolts.

To make it easier to fix the sole of the stand itself, you need to weld a stand under it. It is made from a metal plate 100x100 mm and a channel 50 mm wide.

A piece of the latter is welded onto the plate. Then it is drilled and an M8 nut is welded into it.

You also need to make holes in the corners of the plate. Thus, you can screw the stand onto any surface and install the stand into it permanently.

As a result, we get a mobile stand that just needs to be screwed onto any flat work surface with self-tapping screws. Then the drill is clamped in the clamp, and the attachment is used for its intended purpose.

It is also suitable for drilling against walls or floors without using a stand.