If you need to fix a picture, hook or shelf on a tile, a problem arises with drilling it. If you do this incorrectly, it will simply crack. You can drill through tiles without damaging them, and with a 100% guarantee, if you use these tips.

What you will need:

- Hammer;

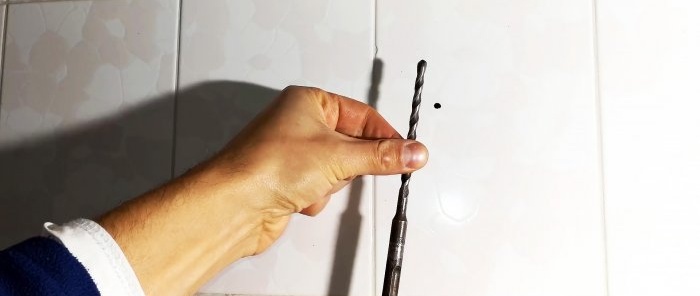

- Drill (bit) for concrete of the required and smaller diameter;

- hammer;

- towel.

The process of drilling tiles with a concrete drill

It is optimal to drill in the center of the tile. The closer to the edge, the higher the likelihood of damage. If it is laid on tile adhesive under a comb without voids, it will remain intact even when drilled in a corner, but usually you do not know how the tiler glued it.

Drilling must be done with a hammer drill in non-impact mode.

If you do not have a special drill for ceramics or glass, then you can use a regular drill for concrete, but first of a smaller diameter. It is important to drill strictly perpendicular to the wall. The revolutions should be low. Do not put pressure on the hammer to prevent the tiles from cracking.

Once the tile is drilled, you may feel that the drill bit has sunk a few millimeters. Immediately it will start throwing out dust of a different color. In this case, the hammer drill can be switched to hammer drilling mode and the hole can be drilled to the desired depth.

Next, you need to drill the hole with a drill of the required diameter. The tile is drilled in the mode without impact, and the wall is already with it.

Afterwards you can hammer in the dowel. To do this, the hammer should be wrapped in a towel so as not to break the tile when the hammer slips.