Almost everyone has an angle grinder, but they may not have a hand-held circular saw or miter saw. If you still need them, then it’s enough to make a special attachment for the angle grinder and it’s a very good idea to replace them. It is simple and does not require turning or other complex manipulations.

Materials:

- Sheet steel 4 mm;

- round timber 30-40 mm;

- strip 20 mm;

- long M10 bolt.

The process of making fixtures on an angle grinder

The sole of the machine needs to be cut from sheet steel. It is made small, literally 20x30 cm, maybe smaller.

A cut is made at the ends and the sole is slightly bent for better fit in the future when working.

A piece of round timber 60 mm long, drilled crosswise in the center, is welded in its corner. Its location and orientation of the hole should be as in the photo.

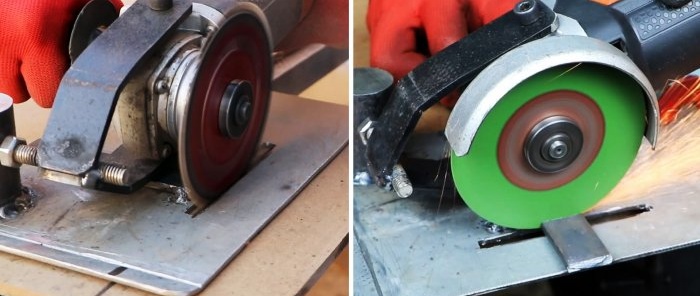

A mounting bracket for an angle grinder is made from the strip.

You need to drill and bend 2 blanks. They are screwed to the angle grinder gearbox into the standard holes for its handle.

Next, you need to insert a long bolt into the barrel welded to the sole and tighten it with a nut.The bracket strips are welded to it, clamped on the grinder. The tool must be aligned so that the cutting disc is positioned strictly parallel to the longitudinal edge of the sole.

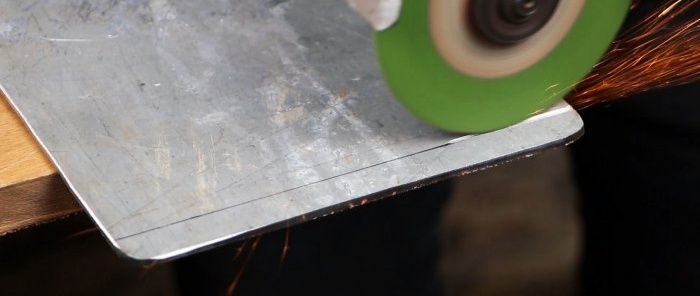

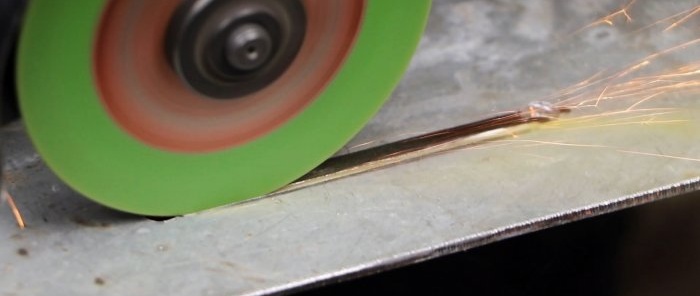

A slot is made in the sole under the cutting disc for it. Then a stop from a strip is welded onto it to level the workpieces when cutting at a right angle.

By screwing the soleplate to the edge of the table, we get a miter saw. The machine can also be used as a hand-held circular saw for cutting sheet materials, moving it along the rip fence.

A mark is made for even cutting.