Polystyrene foam, polystyrene foam and polystyrene foam with a milled quarter allow joining of sheets without cold bridges, resulting in a single rigid plane. However, when we trim, we remove the quarters, so the cut pieces are no longer suitable for use. Having made a cutter of the proposed design, you can cut a quarter on the scraps, thus using them without any residue.

Materials:

- Plywood or MDF;

- wood screws;

- wood glue;

- blades for mounting knife – 2 pcs.

All kinds of cutters on AliExpress at a discount - http://alii.pub/612ag8

Cutter manufacturing process

To manufacture the device, you will need to select plywood or other material whose thickness is equal to half the cross-section of the existing foam or polystyrene sheet. Then you need to cut 3 blanks 200 mm long and 100, 60 and 40 mm wide.

We make the widest one first, and cut it into a trapezoid. Only you need to cut not from the corner, but with an indentation of 10 mm to get a hexagon.

On the second part, 60 mm wide, you need to mark a longitudinal line.It is drawn indented from the edge by half the thickness of polystyrene foam and polystyrene foam. We place a large blank on it according to the mark, and mark the corners along the ribs to cut them down.

We also apply a larger one to the narrow workpiece and align it with the beginning of the oblique ribs. Then we mark them and cut off the corners. We sand the parts so that they are smooth.

The large and medium blanks need to be connected, aligning the line made along the wound. Lubricate them with glue and tighten them with self-tapping screws.

The narrow strip needs to be screwed to the side onto the formed quarter. Be sure to drill before doing this so as not to split the part.

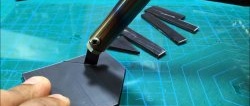

Now you need to screw 2 blades onto the cutter body. Each is fixed with three screws with a wide head. The blades are positioned at an acute angle.

We apply the resulting cutter to polystyrene foam or polystyrene foam, and cut it into quarters moving away from us. Everything is done very easily in one pass. When the cutter becomes dull, we change the blades, and it will cut like clockwork again.

Watch the video

Insulation of floors with penoplex and OSB sheets - https://enn.washerhouse.com/5338-uteplenie-polov-penopleksom-i-listami-osb.html