In residential areas, it is very important to provide access to fresh air. However, when ventilating in the cold season, a significant loss of heat occurs. As a result, heating costs increase. To minimize heat loss during ventilation, recuperators are used. They simultaneously provide an outflow of air from the room and an influx of fresh oxygen from the street. At the same time, they take heat from the outgoing stream and, due to it, heat the supplied air. Such a device can be assembled with your own hands.

Materials:

- Thin pipe 4-10 mm;

- galvanizing;

- threaded rod 6-10 mm;

- bearings - 2 pcs.;

- electric motor;

- drive belt.

Manufacturing process of a rotary recuperator

The length of the recuperator must correspond to the thickness of the wall, or less. It is necessary to measure its cross-section, and then cut thin metal tubes that will be used as filler for the cylindrical body of the device.

Then you need to make the rotation axis of the recuperator. To do this, it is necessary to prepare a threaded rod, which will exceed the length of the prepared tubes by 30-40 mm.

A disc is cut out of sheet metal to fit the diameter of the future recuperator rotor. It is necessary to mark the center on it and cut out the inner surface, leaving 3 knitting needles.

Next you need to make a cylindrical rotor housing. To do this, 2 disks of the same size as the previous part are cut out of wood or plywood. Using them as a template, you need to roll up a cylinder from the sheet metal and connect it with rivets. The body should be 10 mm longer than the prepared fellings.

The tubes fit tightly into the cylinder. The axis should be located in the center. Then a tin circle is installed, and the end of the cylinder is cut with scissors. After this, you need to bend the walls of the housing to fix the flange.

To install the rotor, you need to make 2 fastenings from plywood or boards. A hole is drilled into them, into which a bearing with an internal diameter corresponding to the axis from the stud is pressed. They will be screwed to the wall, and the rotor will thus be able to rotate.

Next, you need to ensure rotation of the rotor. For this, an electric motor is installed. A drive belt is tensioned between it and the rotor. Such a drive can be hidden in the wall, or taken outside it. In the latter case, the connection will no longer be made with the rotor itself, but with the protruding axis.

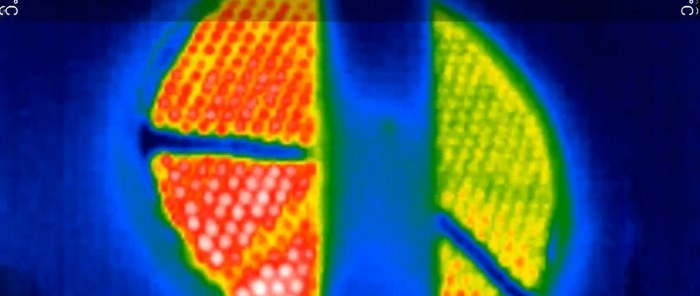

There will be an outflow of air through part of the tubes, and an inflow through the other half. Due to rotation, this is done through the same tubes alternately. First, warm air will come out, which will warm the metal, then cold air will come in and take away this heat. The effectiveness of this device can be seen on the thermogram.

Half of the tubes are clearly warmer, but as they rotate, they cool, and the previously cold ones heat up.