It may happen that standard springs are not suitable for a particular crafts or replacement of a worn-out mechanism or device. For these cases, a device for winding springs of any length, and with further refinement, of any diameter, is most suitable. This does not require expensive materials or high qualifications.

Will need

Materials:- steel equal angle;

- a piece of round pipe;

- steel plate;

- a hairpin and two high nuts;

- screws;

- metal wire.

High-quality drills on AliExpress at a discount - http://alii.pub/5zwmxz

The process of manufacturing a device for winding springs from wire

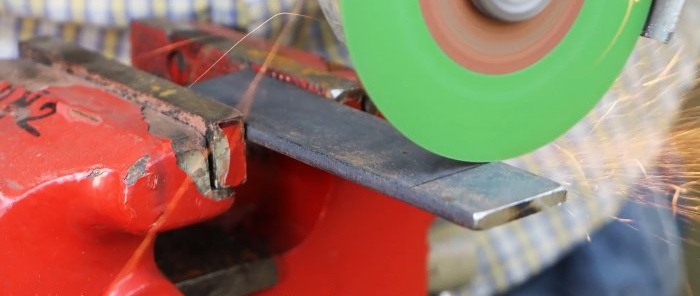

From the equal corner we cut off four fragments of equal length.

We wrap them at a certain distance in pairs in the form of a square around a round pipe of suitable diameter and weld in this position.

We clean the welding areas with a grinder.

We cut off the required length from a steel strip of sufficient thickness. We mark it for four symmetrically arranged pairs of holes at some distance from each other and drill them on a drilling machine. On one side we drill holes for screw heads.

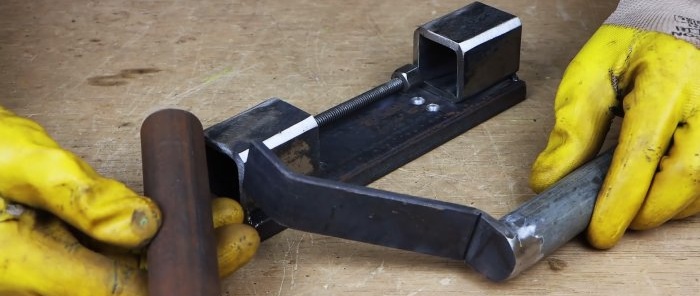

We screw high nuts on both sides onto a stud of the required length and weld them symmetrically in the longitudinal direction to one of the long edges of the plate and clean the welding seams.

We weld two squares, made earlier from corners, to the strip, aligning one of their edges with the corresponding narrow side of the plate, so that a round pipe could be placed in them.

On the second section of the steel plate, stepping back the same distance from the narrow edges, draw lines transversely on opposite sides.

Using a grinder, we make half-thick cuts along these lines and bend the ends of the plate along them in opposite directions at the same angle.

At one end of the pipe we mark and drill a transverse hole in its wall. We install the pipe with its end on the bent part of the plate in the center so that the perforation is on top, and weld.

We also weld a shorter piece of pipe to the other bent part of the plate, but on the opposite side.

We securely screw the plate with two welded squares and a pin to the wooden base. We place a pipe with a hole in the wall inside the squares. Now the device is completely ready for use.

We pass the end of the wire bent slightly upward under the pin and insert it into the hole in the pipe wall. Then, by rotating the handle, we wind the wire onto the pipe, and the density of the winding is ensured by the thread on the stud.The result is a spring, the number of turns of which depends on the length of the original wire.

Welding electrodes and wire on AliExpress at a discount - http://alii.pub/606j2h