Many metalworking enthusiasts would like to try their hand at foundry. This requires the construction of a melting furnace, which requires the use of refractory materials for safe and durable operation. For the average hobbyist, fireclay, fireclay powder and graphite dust are not available, so they try to find an alternative. Most often it is cement, alabaster, putty, sand. We will conduct a practical test of the heat resistance of these materials in their pure form and their mixtures in various proportions.

Production of 7 samples

To test fire resistance, 7 images were created:

- Putty 100%;

- Putty 50%, sand 50%;

- Alabaster 50%, sand 50%;

- Cement 100%;

- Cement 50%, sand 50%;

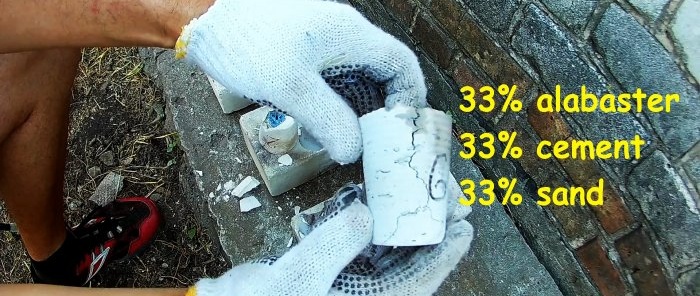

- Alabaster 33%, sand 33%, cement 33%;

- Alabaster 70%, sand 30%.

The materials are mixed with the addition of water and filled into plastic disposable cups. They use a plastic tube as a core. After this, they are set out to dry. As part of the experiment, the samples are dried for 1 day in the shade and 2 in the sun.

After drying, the samples are heated with the flame of a gasoline blowtorch. As a result of the experiment, all materials and their mixtures cracked to one degree or another.

Testing the fire resistance of cement, alabaster, putty and sand

A sample made of pure gypsum putty, despite the crack, continued to hold its shape. Thus, for one-time use this option is quite acceptable.

Putty mixed with sand in equal proportions turned out to be untenable. The sample fell apart. Thus, its fire resistance is insufficient.

A composite based on alabaster with sand in a 1:1 ratio turned out to be durable. Before the start of the test, the sample had the loosest structure of all, but in the end it withstood the heat without destruction.

Pure cement, as expected, cracked, but did not crumble into pieces. The cement with sand in the 5th sample obtained the same result.

A composite of equal proportions of alabaster, cement and sand became covered with a web of cracks when heated. Thus the result is absolutely unsatisfactory for a melting furnace.

The composite, consisting of 70% alabaster and 30% sand, could not withstand the flame.

Watch the video

How to make fireproof putty. The simplest composition - https://enn.washerhouse.com/8438-kak-sdelat-ogneupornuju-zamazku-prostejshij-sostav.html