Pure concrete blocks are quite massive and do not have high thermal insulation characteristics. If, along with traditional components in the form of cement and sand, granulated polystyrene foam is used in a certain proportion, then their thermal insulation qualities increase and their weight becomes less. The result is a triple benefit: on the one hand, the walls can be made thinner, on the other, the labor intensity of the work is reduced due to the lower weight of the wall materials, and thirdly, transportation costs are reduced.

Will need

Materials:

- granulated or crushed polystyrene foam;

- high quality cement;

- sand without impurities;

- technical water.

Tools: wooden rectangular shapes, a powerful drill with a stirrer, containers for dosing and mixing the solution, a scoop shovel, a metal trowel or a construction trowel, an electronic digital steelyard, etc.

The process of making concrete blocks with the addition of granulated polystyrene foam

We stock up on 50 liters (by volume) of granulated polystyrene foam, the required amount of high-quality cement and ten buckets of clean sand. We prepare concrete mortar for making wall blocks in the following proportions: 1 kg of cement, 1 liter (by volume) of polystyrene foam granules and 4 liters of sand, also by volume.

In a suitable container for mixing concrete mortar, we pour sequentially granulated polystyrene foam, clean sand, cement taking into account the above proportions and water with some excess to make it easier to mix the components and obtain a homogeneous mass using a powerful drill with a stirrer.

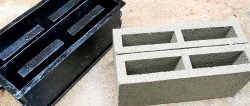

Having achieved homogeneity of the concrete solution, we fill it with a wooden rectangular form of the given dimensions, laid on a flat surface in the form of a mat made of plastic, rubber or simply plastic film.

Then, using a metal hammer or a construction trowel, we fill the corners of the form and smooth the surface of the concrete solution. After allowing the concrete mixture poured into the mold to sit for some time and set, we remove the mold and allow the block to dry naturally and gain strength and hardness.

By the way, if granulated polystyrene foam is not available, then it can be replaced with packaging material, which must be finely crushed, and used instead of the granular form. The quality of the blocks will not suffer from this.