In your home workshop or workplace, there is always a use for metal scissors. Such a factory-produced tool is expensive. But you can make them yourself from an old car spring with some metal handling skills.

Will need

Materials:

- car spring leaf;

- spur gear;

- bolt and nut;

- channel section;

- cylindrical axis;

- steel rod;

- spray paint, etc.

Tools: core and hammer, calipers, vice, clamps, grinder, drilling machine, welding, gas-acetylene torch, quenching oil, etc.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

The process of making heavy-duty tin snips from old car springs

We disassemble the old spring and select a suitable leaf.

We mark it using a round washer and a caliper set to a certain size.We place one leg in the center of the semicircle outlined around the washer, and with the other we draw a circular arc along the spring leaf.

We roll the gear along a circular arc on the spring so that the tops of the teeth touch the arc, and outline the profile of the teeth on a section of the spring leaf from one end to the other.

We clamp the marked section of the spring leaf in a vice and cut out the profile of the teeth. We check the accuracy of the gear engagement of the teeth in the spring and gear. We also attach the previously marked contour to the other end of the spring section.

We drill a hole in the center of the semicircle on the spring and place it on another section of the spring. We transfer the center of the circle and draw two lines, one along the flange of the upper part, the second - radially to the semicircle.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

We remove the upper part and draw a third line on the lower one, slightly expanding the outlined contour. Next, drill a hole and make a cutout along the contour.

To the two parts obtained from the spring, we add a third, in which we also mark and make a hole and a cutout consistent with the first part.

We connect all three parts with a bolt and fasten with a nut. Moreover, the part with the teeth should be in the middle. We check the freedom of rotation of the middle part around the bolt relative to the side ones.

We place this package of three parts edgewise on the back of the channel from the outside so that the cutouts in the parts are directed towards the top.

We weld the side part with a wide cutout to the channel using electric welding, and fasten the other part with gas-acetylene soldering so that it can be removed and sharpened as necessary.

We also weld a strip of springs to the ends of the side parts in front to increase the strength and rigidity of these elements.In two rectangular fragments cut from the same spring, we drill holes of a given diameter.

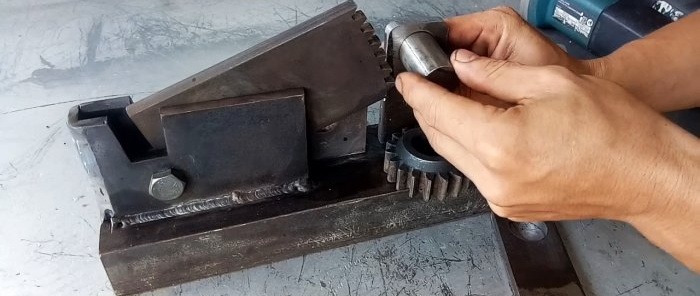

We insert an axle into the hole of one fragment, put a gear on it, which we engage with the teeth at the end of the spring part. And finally, we put the second fragment on the axle.

We place the resulting assembly on the back of the channel so that the engagement of the gear teeth and the spring parts is complete and reliable. After this, we weld the bases of the fragments to the back of the channel.

We insert a strong steel rod into one of the interdental cavities of the gear from above, direct it slightly forward while the middle part of the spring is in the lower position, and weld it.

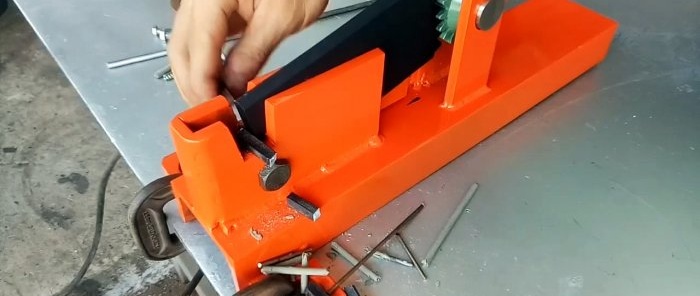

We heat the cutting edges of spring parts in a gas-acetylene welding flame and cool them in quenching oil to increase the hardness and strength of the working parts.

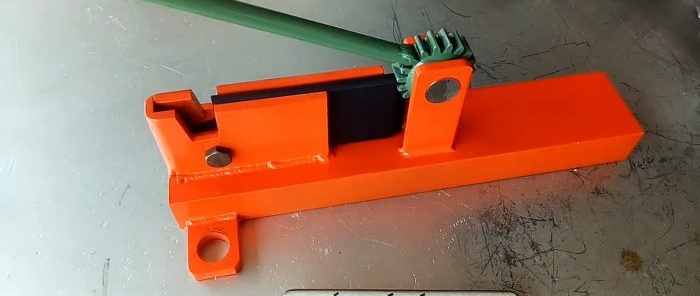

In principle, the scissors for cutting metal are ready. All that remains is to paint their parts, taking into account functionality and design.

Watch the video

Another design: how to make powerful tabletop metal shears - https://enn.washerhouse.com/7729-kak-sdelat-moschnye-nastolnye-nozhnicy-po-metallu.html