If in a home workshop or even at a workplace there is a need to bend a box-shaped profile at a right angle, in particular, a profile square pipe, then it is possible to use a fairly simple method, mainly consisting of original markings and subsequent cutting with a grinder. Any adult can perform such a simple operation and does not require special knowledge, professional skills, expensive material or special tools.

Will need

Materials and tools:

- profile square pipe 30 cm long;

- marker, measuring square and caliper;

- grinder with cutting disc;

- hand file for metal;

- magnetic square;

- welding equipment.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

The process of ideal bending of a profile square pipe at right angles

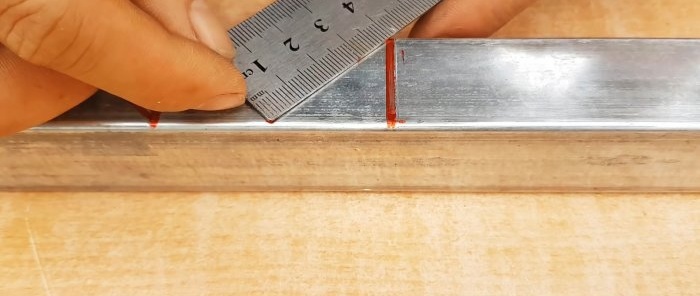

We mark the middle (15 cm from any end) of a profile square pipe 30 cm long with a transverse line.We draw two lines from this mark on the right and left using the same piece of profile square pipe, which are spaced from each other exactly the length of the side of this box-shaped profile.

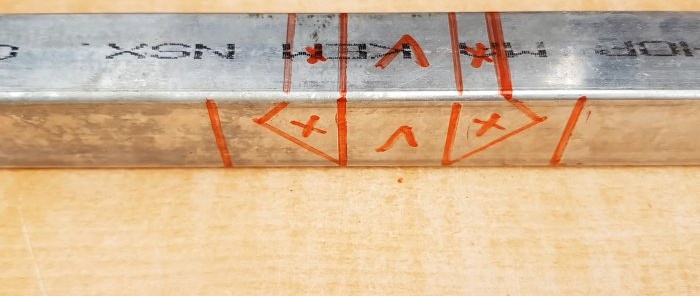

We continue these four lines along the surfaces of two adjacent sides of the profile square pipe, without violating their parallelism and the distance between them. We connect two left and two right lines with a diagonal. We do the same on the opposite side of the box profile.

We measure the size of the side of the square pipe with a caliper and mark it on diagonals from the inner ends towards the outer. We draw perpendicular lines from the corresponding points on the edges of the pipe to all these marks, the ends of which are connected along the adjacent side of the profile square pipe.

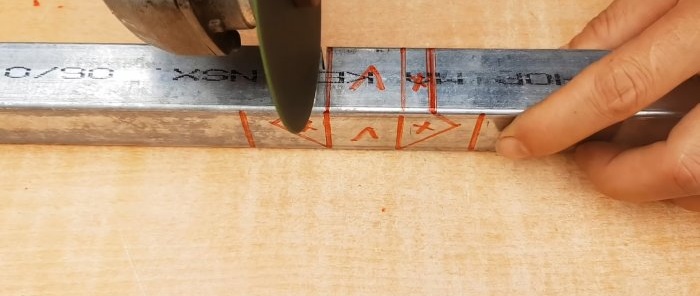

We mark with a cross the areas to be cut, which we do with the help of a grinder.

We remove the cut out areas and clean all cutting lines with a hand metal file, removing burrs formed during cutting and smoothing out sharp edges.

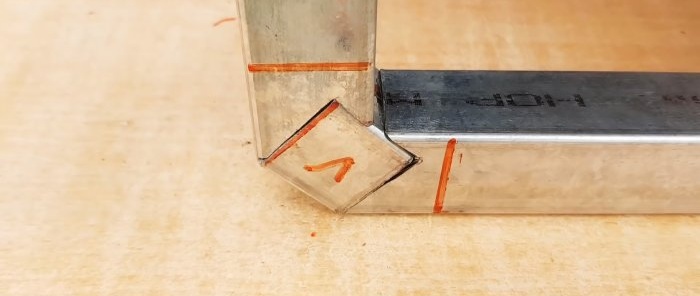

All that remains is to bend the ends of the square pipe towards each other so that the cutting lines close around the central box-shaped element.

We place a magnetic square in the inner corner, squeeze the ends of the profile pipe again and perform tack welding along the contact lines using a welding machine. Or we twist it with a corner using metal screws.

Using a grinder, we clean the tack areas and make sure that the profile square pipe is bent exactly at 90 degrees.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly