The welding machine is based on a high-voltage, high-frequency converter. Built on the principle of a blocking oscillator with deep transformer feedback. The generator generates short-term electrical pulses, repeated at relatively large intervals. The clock frequency is in the range of 10-100 kHz.

The transformation ratio of this circuit will be 1 to 25. This means that if you apply a voltage of 20 V to the circuit, then the output should be about 500 V. This is not entirely true. Since any pulse transformer source or generator without load has powerful high-voltage pulses reaching a voltage of 30,000 V! Therefore, if you disassemble any Chinese pulse charger, you will see a soldered resistor parallel to the output capacitor.This is also a network load; without a resistor, the output capacitor will quickly leak due to excess voltage, or worse, it will explode.

Therefore, attention! The voltage at the transformer output is dangerous to life!

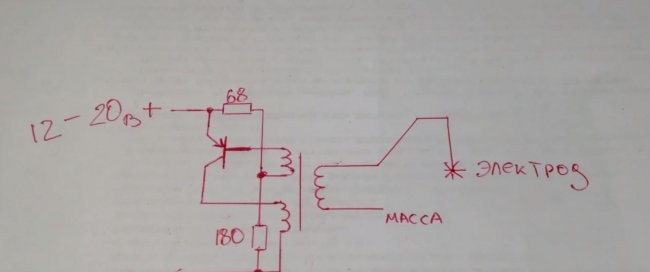

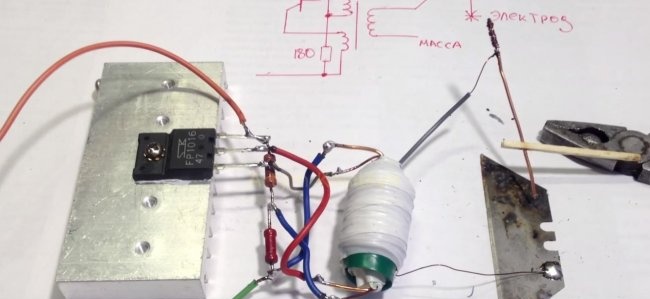

Mini welding machine diagram

Required parts:

- The transformer is homemade, the manufacturing procedure is described below.

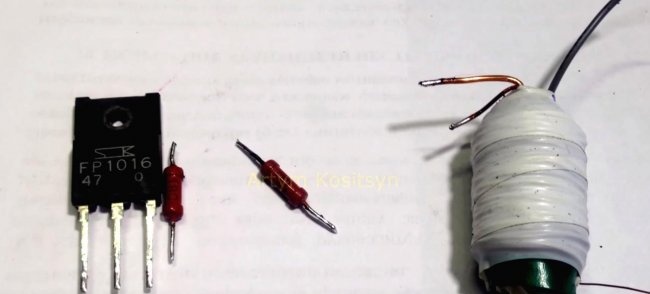

- Resistors - 0.5-2 W power.

- The transistor used was FP1016, but it is difficult to find due to its specificity. Can be replaced with transistor 2SB1587, KT825, KT837, KT835 or KT829 by changing the polarity of the power supply. Another transistor with a collector current of 7 A, a collector-emitter voltage of 150 V, and a high gain (composite transistor) is also suitable.

The transistor must have a heat sink installed. Although this is not on the diagram, it would be a good idea to place a filter capacitor in parallel with the source so that all interference from the operation of the blocking generator does not penetrate the source.

Transformer manufacturing

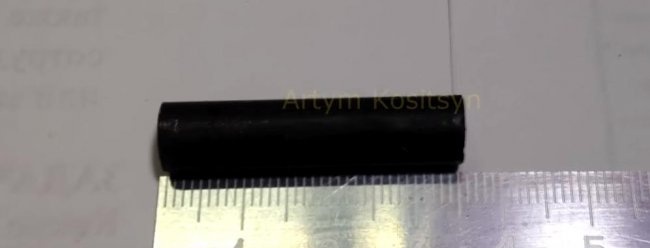

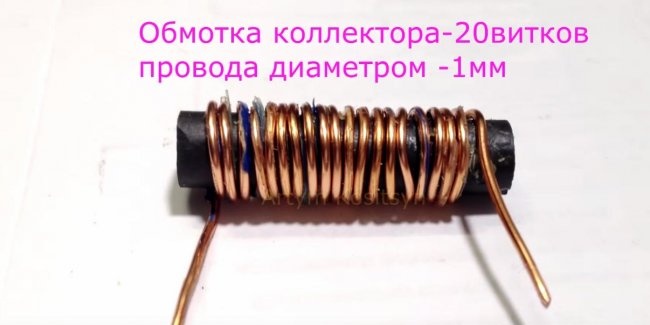

The transformer is wound on a piece of ferrite rod from a radio receiver.

- The collector winding is 20 turns of 1 mm wire.

- Base winding - 5 turns with a 0.5-1 mm rein.

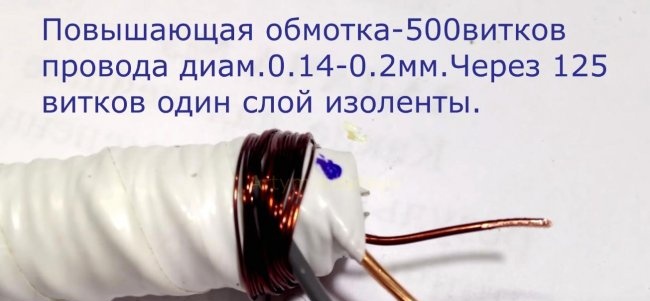

- High-voltage winding - 500 turns with a drive of 0.14-0.25 mm.

All windings are wound in one direction. First is the collector winding, followed by the base winding. This is followed by three layers of white electrical tape insulation. Next, we wind the high-voltage winding, 1 layer of 125 turns, then insulation, then repeat. In total, you should get 4 layers, which is equal to 500 turns. We also insulate the top with white electrical tape in several layers.

Let's put together a diagram. If everything is in order, everything should start without problems. Since the operating frequency of the generator exceeds the sound frequency, you will not hear a squeak during operation, so you should not touch the output of the transformer with your hands.

Start the generator with a voltage of 12 Volts and increase if necessary.

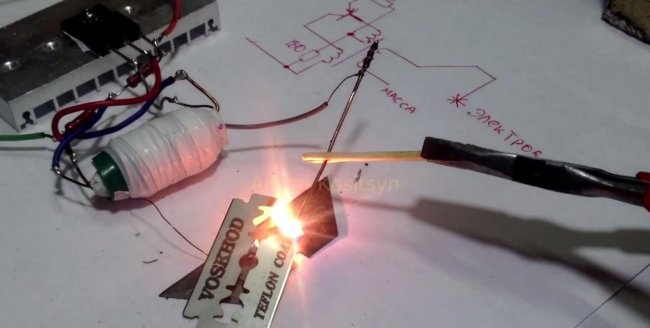

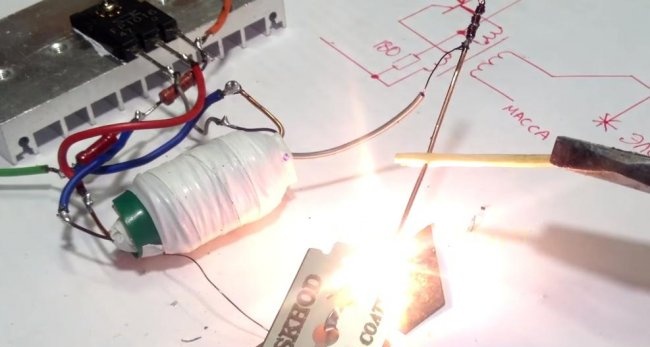

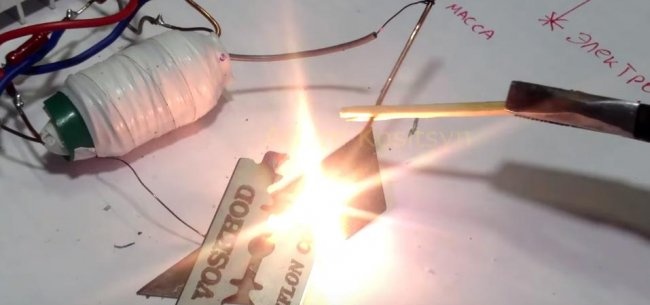

The arc is ignited from a distance of 1 cm, indicating a voltage of 30 kV. The high frequency does not allow the burning arc to break, as a result of which the arc burns very stably. When using a copper electrode in close contact with another electrode, a plasma medium (copper plasma) is formed, resulting in an increase in the temperature of arc welding and cutting.

Welding machine testing by cutting and welding

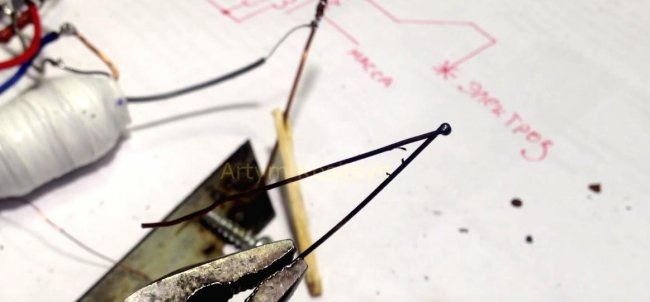

We cut the razor blade with an arc.

We fuse copper wires up to 1 mm thick.

Thick copper wire was used as an electrode. It is clamped in a wooden match, since dry wood is also a good insulator.

If you liked this small welding machine, then you can make it larger in size and power. But be extremely careful.

Also, to increase power, you can assemble a generator using a push-pull circuit, and even using field-effect transistors, like here - Simple 12V Induction Heater. In this case, the power will be decent.

Also, do not look at the bright arc discharges with the naked eye; use special safety glasses.

Watch a video of making a welding machine using a blocking generator

Author of the homemade video - Artym Kositsyn