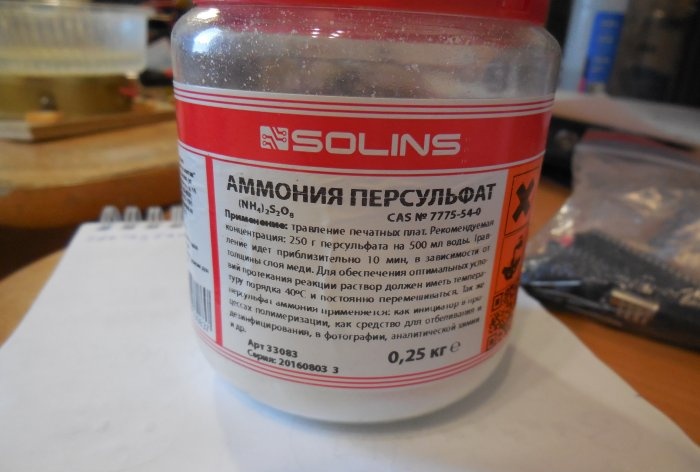

There are quite a lot of ways described on the Internet on how to etch a printed circuit board in a solution of ferric chloride or hydrogen peroxide with citric acid. At the same time, another method of etching is unfairly forgotten - in a solution of ammonium persulfate. It combines high etching speed, low cost of ingredients, and ease of operation. Ammonium persulfate can be bought in radio parts stores; it costs about the same as ferric chloride.

It is a white powder with a slight chemical odor.

So, how do you etch a board in an ammonium persulfate solution?

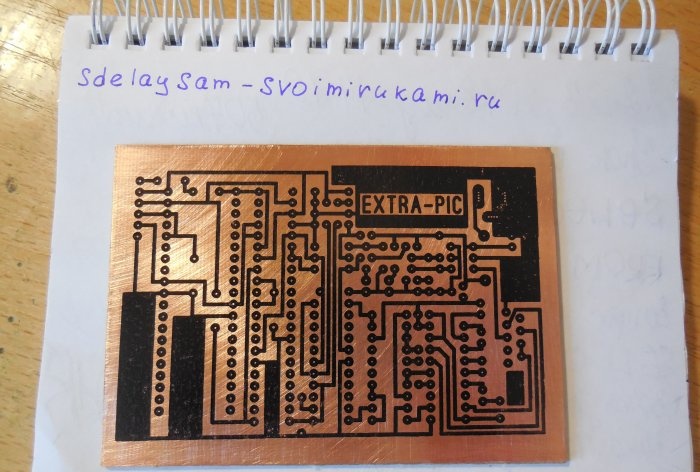

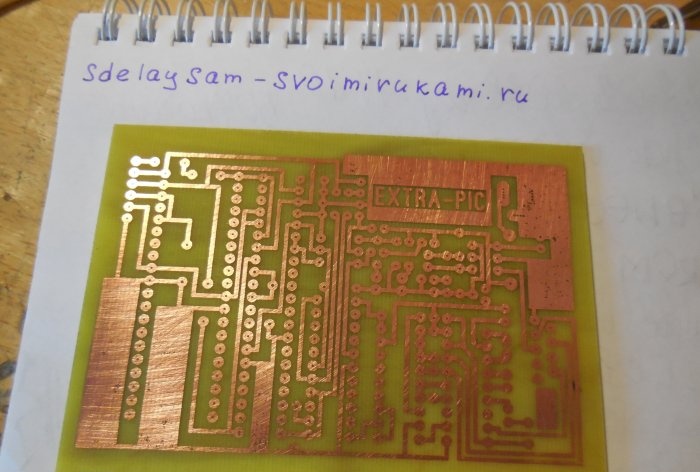

Step 1. Prepare the board from which you need to bleed copper. The tracks can be drawn with a permanent marker, nail polish, or the drawing can be transferred from a computer using LUT, photoresist. I use laser ironing technology.

Step 2. Mix the etching solution. The instructions on the jar of the chemical indicate the proportions “250 g of persulfate per 500 ml of water,” but with such proportions the etching rate is very low and the consumption is enormous.Experimentally, I found that the etching speed is maximum if you mix 1 part persulfate to 8-10 parts water (1: 8-10). The powder consumption is quite small. It also doesn’t hurt to add a little table salt to the solution; this will have a positive effect on the etching speed. You need to take ammonium persulfate with a plastic or wooden spoon, no metal. The container should also be plastic.

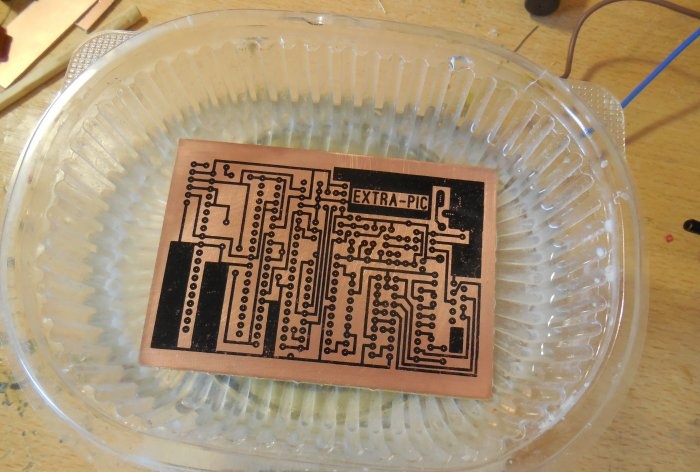

The peculiarity of etching boards in ammonium persulfate is that the solution must have a temperature of more than 40 degrees, otherwise the reaction will not occur at all. Therefore, you need to take water that is warm enough so that it does not have time to cool down while the board is being etched. It’s also not worth going overboard with the water temperature, as the tracks may move away. You can also heat the board during the etching process, for example, in a water bath or using a homemade electric stove, as I do.

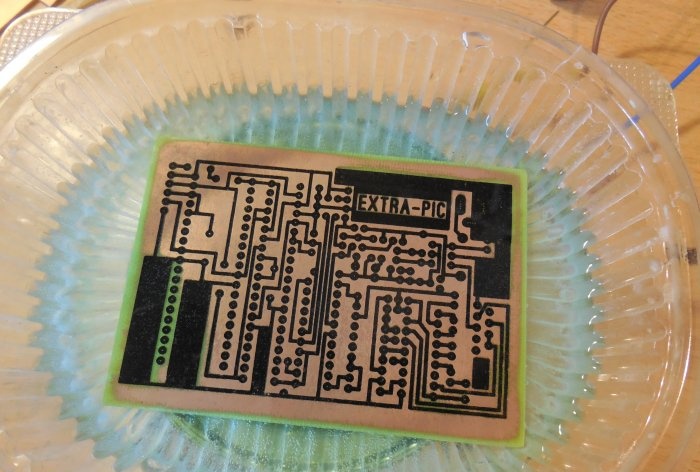

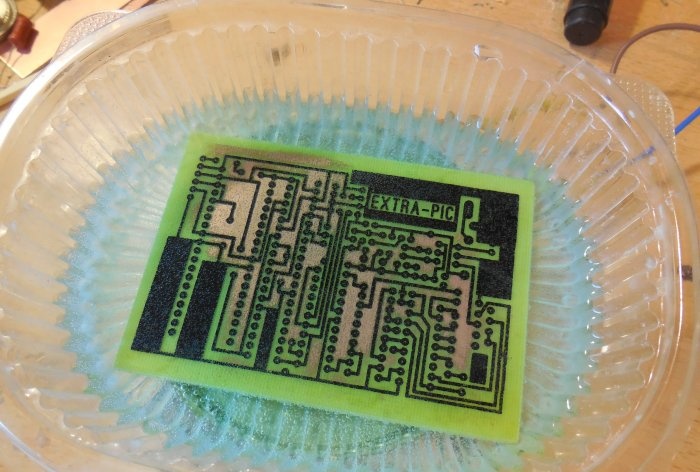

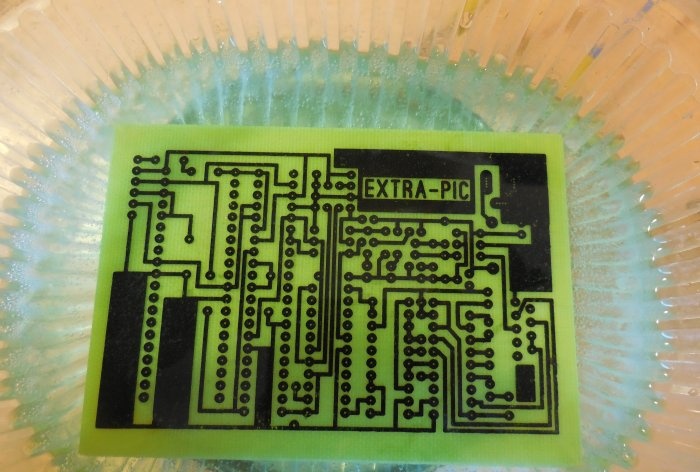

Step 3. Lower the board into the warm prepared solution. The etching process begins immediately. It doesn’t hurt to periodically rock the board in the solution, stirring it. The advantage of ammonium persulfate is that its solution, unlike ferric chloride, remains transparent, and you can monitor the progress of the process without removing the board. In addition, when etching in persulfate, almost no gas bubbles are released, as in a hydrogen peroxide solution, the tracks do not come off, and the board does not float to the surface.

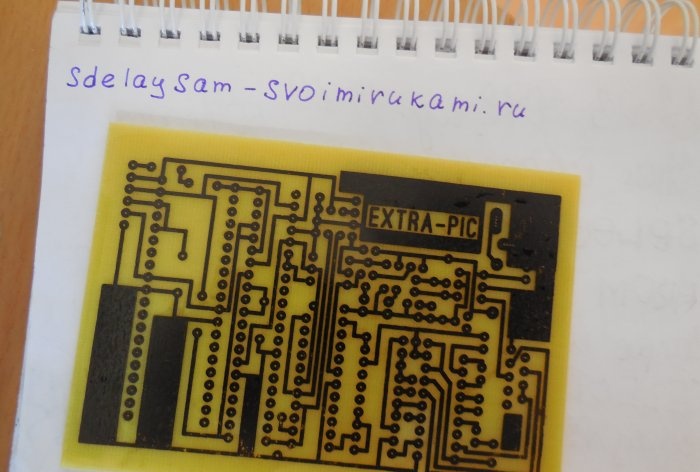

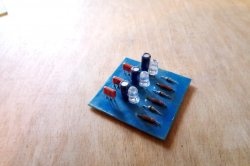

After 20 minutes, the board was completely etched, now all that remains is to remove the toner, drill holes, and tin. Thus, this etching method is a good alternative to the popular ferric chloride and hydrogen peroxide.

Advantages:

- High etching speed.

- Transparency of the solution.

- No bubbles.

Flaws:

- The need to heat the solution.

- Ammonium persulfate is a rather rare product in stores.