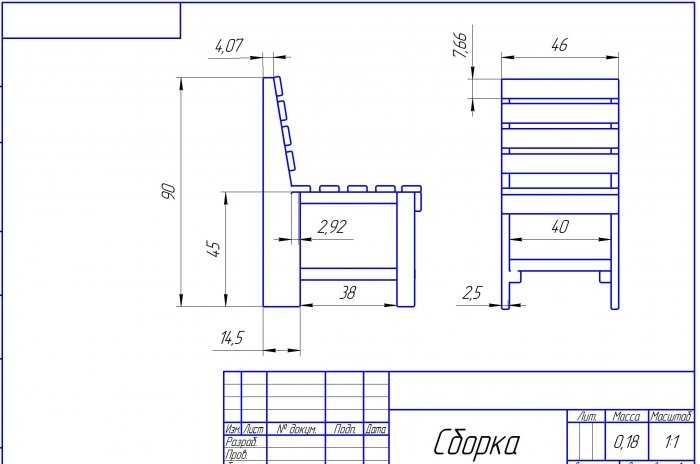

The article describes in detail and shows how, with the help of these two “helpers,” you can make a durable, reliable and, moreover, aesthetically attractive garden chair. A three-dimensional model and a drawing with dimensions will help you quickly navigate the project and correctly manufacture the parts of the future item. furniture. The material also contains some recommendations for assembling and processing a wooden chair.

Materials

To make a garden chair you will need a cut pine board 25-30 mm thick and 140 mm wide. Also, for the manufacture of lintels, a wooden beam of 5050 mm is needed. These parts can also be made from boards, but this will significantly reduce the strength of the structure. The garden chair will be used in harsh conditions, so a margin of safety will not hurt.

All structural elements are connected using self-tapping screws and wood glue.At the same time, as can be seen in the photographs presented, the fasteners themselves are not visible. To “disguise” them you will need standard 8mm furniture dowels. The length of the screws is 30 mm.

Now for the amount of materials:

- Board – 5 m.

- Beam – 2.5 m.

- Self-tapping screws – 60 pcs.

- Dowels – 20 pcs.

Wood glue, by and large, is only needed for gluing dowels, so it will take very little of it. If you do everything “smartly”, that is, glue absolutely all the connections, then you will use about 50-100 grams.

Tools

The main idea of the material is to use a minimum of tools that any home craftsman has to make a garden chair. Whatever one may say, you should prepare the following:

- wood hacksaw;

- drill;

- wood drill with a diameter of 2.5 mm;

- wood drill with a diameter of 8 mm;

- a bit for self-tapping screws (you can also use a screwdriver);

- 100 grit sandpaper;

- carpenter's square;

- roulette;

- simple pencil.

The following tools and accessories will help simplify and speed up the process of manufacturing parts and assembling a garden chair:

- jigsaw;

- a circular saw;

- electric plane;

- sanding machine (preferably orbital);

- carpentry clamps.

But if all this is missing, it doesn’t matter. The minimum from the first list is quite enough. In terms of time, however, it will take much longer.

Details of a wooden garden chair

The best place to start is by making the back legs. These are the most difficult parts of the chair, since there is an oblique cut of the board. It is necessary so that the back has a certain slope, which improves the comfort and attractiveness of the chair.

Next, longitudinal and transverse jumpers are cut from the timber.As mentioned above, it is quite possible to make these parts from the same 30 mm board. But it’s better, nevertheless, to use timber.

The last step is to make the front legs and slats to finish the seat and backrest. In the example given, for this purpose, a 14-centimeter edged board was unfurled lengthwise. In principle, it is quite difficult to perform such an operation manually. Therefore, if you don’t have a jigsaw or a circular saw, you can use a whole board 14 cm wide. Although narrow slats look more attractive on the finished product. In addition, if your edged board is not very smooth, longitudinal sawing will make it easier to fit the parts to the required size.

After cutting all the elements of the garden chair, it is recommended to immediately process them with a plane and sandpaper. To improve the appearance, it is advisable to round all the edges that will be on the outside. Even if you don’t have a plane or a special grinder, we take a drill, a disk attachment and abrasive wheels with a grain size of 100 units. The chair shown in the example was completely processed using only this set (not even a plane was used).

To extend the life of the sandpaper, it must be periodically cleaned of chips. To do this, the easiest and cheapest way is to use insulation in the form of foamed polyethylene (the one that is covered with foil on one side). If you “walk” sandpaper over such polyethylene, it will be completely cleaned. This method does not work only against tar plaque. When the paper becomes clogged with resin, all that remains is to throw it away.

Stages and nuances of assembling a wooden chair

The technology for connecting all parts of the chair is the same. It's called the "invisible screw".

The execution sequence is as follows:

- The parts are gradually applied to each other as shown in the drawings and photographs. For convenience and greater accuracy, they are fixed with clamps.

- Holes with a diameter of 2.5 mm and a depth of 30 mm are drilled for self-tapping screws.

- In the same places, the holes are expanded with an 8 mm drill to a depth of about 10 mm.

- Self-tapping screws are screwed into the holes. To make them go easier, it is recommended to lubricate the tip with regular motor oil.

- Wood glue is applied to the remaining holes and dowels are driven in.

- After the glue has dried, the protruding parts of the dowels are cut off with a hacksaw.

If you do not secure the parts with clamps, they may move during the drilling process. If holes are not first made for the screws, then when screwed in they can split the material. Unevenly sawn dowels can subsequently be easily polished “to zero” and look much more aesthetically pleasing than open self-tapping screws. Additionally, the places where the parts come into contact can be treated with wood glue. This assembly will be more professional.

The process begins with the longitudinal jumpers and the front leg being attached to the rear leg. There will be two such assemblies. During the process, special attention should be paid to ensuring that the parts are perpendicular. The right angle is controlled and checked with a carpenter's square.

Next, you need to connect the resulting sides at key points. For a chair, this is the lower rear crossbar, as well as slats - the upper one on the back, and the front one on the seat. It is better to connect only one screw at each point at once. If perpendicularity is violated, the situation can be easily corrected. Only after this a second self-tapping screw is added to the key connections.

All that remains is to evenly distribute the remaining lamellas and secure them in the manner described above.It is better to use two self-tapping screws at each point. This way the structure will be as rigid as possible and, accordingly, reliable.

After assembly, the final polishing of the product is carried out. At this stage, you can remove many errors made earlier. The remaining dowels are also sanded. The decorative and protective finish of the chair is not shown in the photographs, since the required material (tung oil) was not available at the time of assembly. For these purposes, you can also use wood stains, glossy or matte varnishes.

Results and cost of a garden chair

If you work only with a hacksaw and a drill, then it will take about 8 hours to make the parts and assemble them. In a well-equipped carpentry workshop, 3-4 hours will be enough.

At cost. The board and timber to make one such chair cost about $5. Self-tapping screws and dowels – $1.50. Sandpaper and used glue are another $1. Decorative oil treatment - about $2. In total, the cost of a DIY garden chair is less than $10. Naturally, it is unrealistic to buy solid wood furniture in a store for that kind of money.