Required materials

Before starting to manufacture the press, you will need to purchase or find in the bins:

- steel square pipe 50x50 mm;

- steel corner 40x40 mm;

- steel strip 40x4 mm;

- steel plate 10 mm;

- steel plate 4 mm;

- 5t bottle jack;

- 2 coil springs for trampoline;

- 2 J-bolts with nuts;

- 12 M10 x 60 mm bolts with nuts;

- 2 M10 x 80 mm bolts with nuts;

- 2 M10 bolts for a hex key 30 mm long;

- 4 M8 bolts for a hex key 16 mm long;

- 2 M10 x 16 mm bolts;

- 4 M6 x 16 mm bolts;

- 1 M10 x 30mm hex bolt

- rod with heel.

The process of making a hydraulic press from a jack

To begin, cut 2 blanks from a square pipe. They will later be used as the main stand of the machine. I selected their length to match the parameters of the jack. I got 66 cm. I also immediately make legs from the corner. To ensure their stability, a length of 30 cm is sufficient.

Using a core, I apply markings for drilling on the corner, after which I prepare 2 holes for M10 bolts. I place the corner in place on the square pipe and align it at 90 degrees to make a marking for drilling. I prepare a through hole through both walls of the square. Now I connect the pipe and the angle with long bolts and nuts.

After the racks are ready, I cut two blanks from the corner, each 40 cm long. They will be used as an upper reinforced stop for the jack. I place them one by one in place and mark them for drilling. I first make holes in the corners, after which I also drill the square.

I insert 2 M10 bolts on each side. I pull the stand and both corners together.

From an existing thick steel plate, I cut out a rectangular blank measuring approximately 80 by 13 cm. The jack piston will rest against it. Now I turn the rack over so that the transverse corners are at the bottom. I lay the plate across and drill in its center.

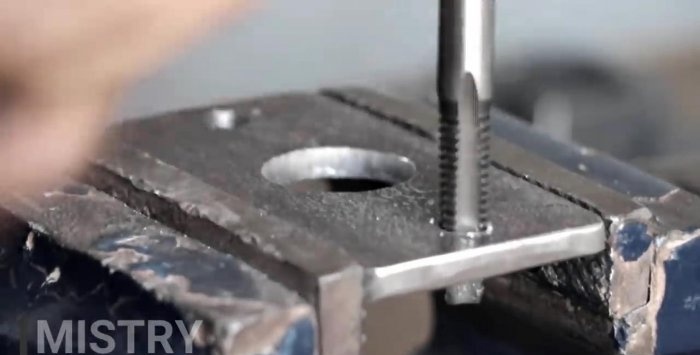

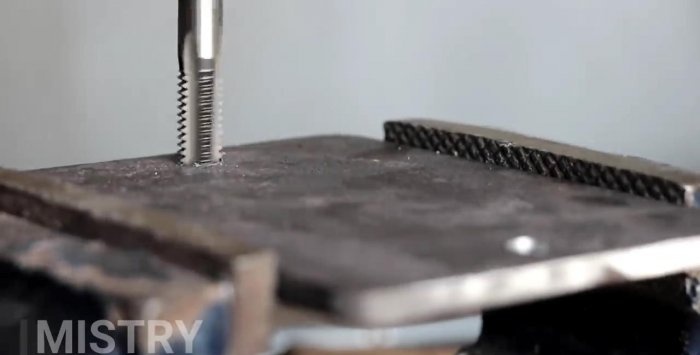

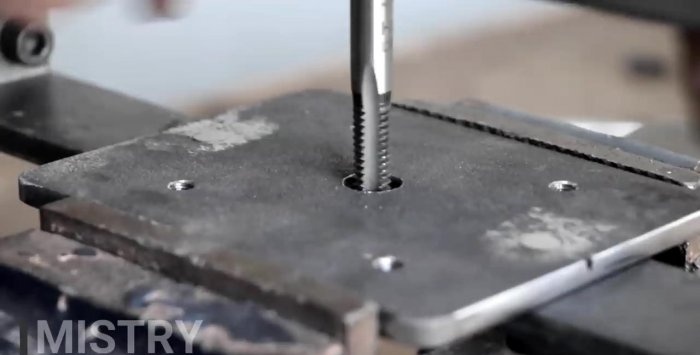

To prevent the jack cylinder rod from slipping under load, a limiter is required. To do this, I cut out another plate, but a little smaller. To do this, use a thin 4 mm plate. I make through holes on it, transferring them from the large plate. Also in its center, using a milling cutter, I select a large diameter hole into which the heel of the jack piston will fit.To avoid using nuts, I cut the threads in a thin plate. Now I attach both plates to the support from the corners and twist everything with M10 bolts (30 mm long with a hex key head).

Now I’m making a sliding support to secure the bottom of the jack. It will not be subject to serious loads, so I decided to make it from a steel strip.

To begin with, I cut two pieces 16 cm long. I made two transverse marks on them at a distance of 5.4 and 10.8 cm from one of the edges. Then I sharpen the wedge-shaped cut with a grinder, but do not cut it completely. I bend the strip along the resulting groove, obtaining a U-shaped profile that easily slides along the machine stand.

Having attached the profile in place to the rack, I measure the distance between them, while subtracting 4 mm for the tolerance. I transfer the dimensions to the steel strip. Its length should be 8 cm longer. I make a mark, having first retreated 4 cm from the edge. After this, I cut wedge-shaped grooves with a grinder in a similar way. I bend the tails obtained along the edges of the strip at 90 degrees.

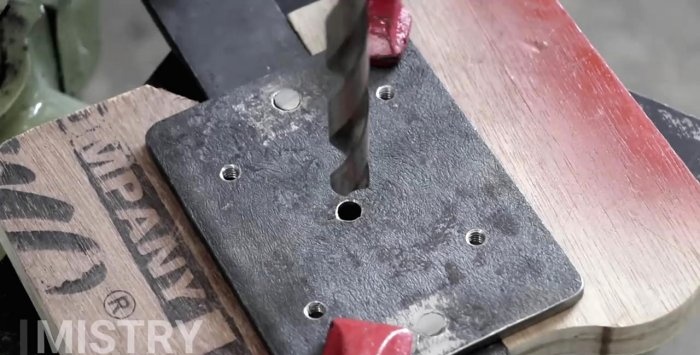

Now you need to connect the blanks obtained from the strip. To do this, I first drill holes in the tails and immediately cut threads into them so as not to use nuts later. I also prepare holes in the U-shaped profile and connect everything with M8 bolts with a hex key head 16 mm long.

Next, I take a steel plate with a cross-section of 4 mm and apply the bottom of the jack to it and trace it, make tolerances and cut it. I try on the resulting workpiece in the center of the lower support made of a steel strip. I make 2 holes and cut the thread. I connect the plate and the stand, then cut off the extra length of the bolts.

I make four holes in the bottom of the jack.After that, I apply it to the bottom stop plate, mark it and drill. I also cut threads.

I make a through hole in the center of the jack support plate. Then I partially expand it to fit the head of the M10 bolt, but I don’t drill all the way through, just to recess the head.

On a steel strip with guide profiles, stepping back a few centimeters from the base plate, I make a hole. They will be useful for securing the springs in the future.

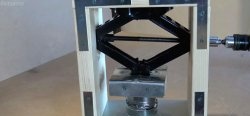

I am starting to assemble the moving part of the machine. First, I screw an M10 bolt into the central hole of the plate using a hex key. Its head is completely hidden. I put a jack on top and secure it with small bolts, also with a hex key. I insert J-bolts into the side holes on the strip. I tighten them with two nuts.

Now on the top stop of the machine, opposite the J-bolts, I make transverse through holes through both corners. I insert the bolts and connect them with springs to J hooks.

I take the steel angle again and cut off 2 pieces of 40 cm each. They will be used as a stand for placing pressed blanks. I drill in the same way as I used when attaching the top stop of the jack. To add rigidity, I made 2 inserts from sections of square pipe; they will also prevent the platform from warping and falling when rearranged.

Now the final stage. I take a steel rod with a heel and cut it to the required length.

I make a hole in its end for an M10 bolt. I cut the thread and screw the rod to the bolt that was previously screwed into the center of the lower stop of the jack.

All that remains is to make through holes along the racks in order to be able to change the height of the platform to the required parameters of the workpieces.I have only made a couple so far, but in the future I will drill them if necessary.

You can start testing. The standard jack handle is not comfortable, so I replaced it with a longer tube.

To protect against corrosion, I painted everything red and black.

I avoided welding during assembly because getting the angles right is important. When welding, the part may move to the side. As you know, misalignment, pressure and welding seams are incompatible. The main advantage of the design is that, if necessary, I can always remove the jack and put it back.