In the case of round pipes, fittings sometimes help. There are no such solutions for rectangular and square pipes. Bolt-on mounting only is offered.

Making a pipe bend by welding it from separate segments is not the best way out of the situation. It's difficult, and usually unreliable.

The most technologically advanced option that has been proven for decades has been and remains a pipe bender, which allows you to bend a pipe of any cross-section without compromising its quality and performance characteristics.

You can make such a compact machine with a mechanical drive with your own hands. It will take some work, but it's worth it. You won't be able to buy a pipe bender cheaply. The minimum price in stores for a device that looks more or less worthwhile starts from several thousand rubles. At the same time, one can only guess about its quality and service life.

What you need for a homemade pipe bender

A homemade machine will consist of at least 50% of available materials. Something will definitely be found in personal households, something in neighbors’ garages. Most likely you will only need to buy 8 bearings of the 303 series. They are designed to perform the function of shafts, which eliminates the need for turning work. Such bearings are inexpensive, and if you look, you can find them for pennies. If you have to buy some additional iron, it’s almost nothing compared to the store price of a pipe bender.

You will definitely need a section of channel 80x40 mm, a steel angle 25x25 mm, a profile pipe 20x20 mm, a construction pin with a diameter of 18 mm, 6 M18 washers with an increased outer diameter of 56 mm, 9 nuts for 18 and some other small things, but more on that in the process .

The main tools are a grinder, a welding machine, and a drill.

Order of operations

1. We take an 80x40 mm channel as the basis for the design, mark and cut a workpiece approximately 40 cm long.

2. Clean with a metal brush attachment.

3. Use a grinder to partially remove the thread from the stud so that the bearings, the inner diameter of which is 17 mm, fit loosely but tightly onto it.

4. Using a circular saw or grinder, cut three sections from the stud - they will be used to make rollers. We take the length of the segments with a margin (approximately 100-120 mm), taking into account the width of the washers, bearings, and nuts. We'll remove the excess later.

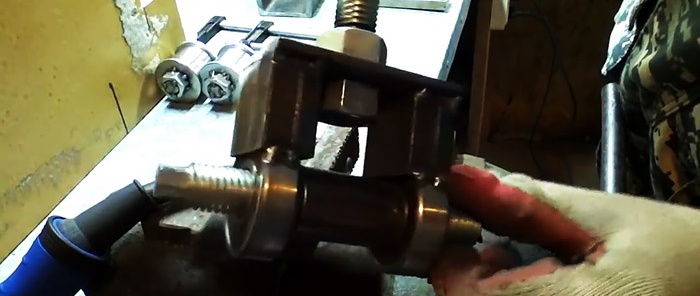

5. Using a mandrel and a hammer, set a slight taper for the washers - within 1 mm, which will ensure free rotation of the rollers.

6. Assemble the roller and tighten the nuts.

7. Remove the part of the stud protruding beyond the nut.

8. Using electric welding, we point-fix the elements of the roller.

9. Check the roller for free rotation.

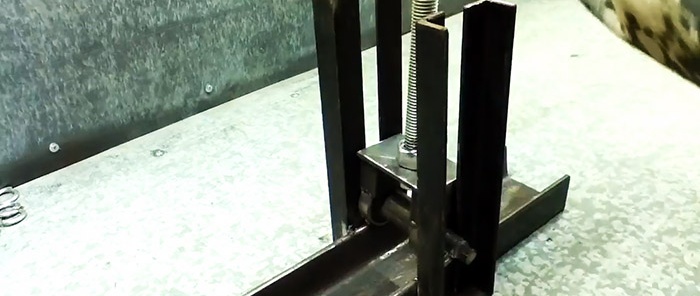

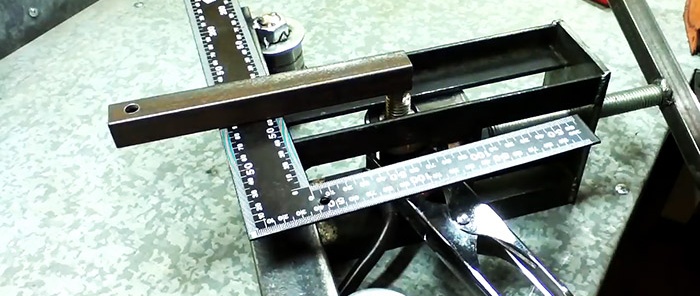

10.We mark and cut four 25 cm long segments from a 25x25 mm corner to make guides for the drive and pressure rollers.

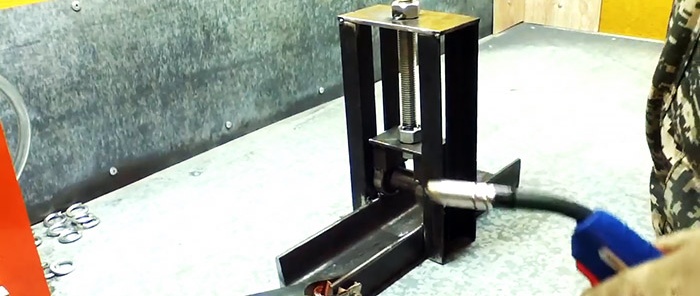

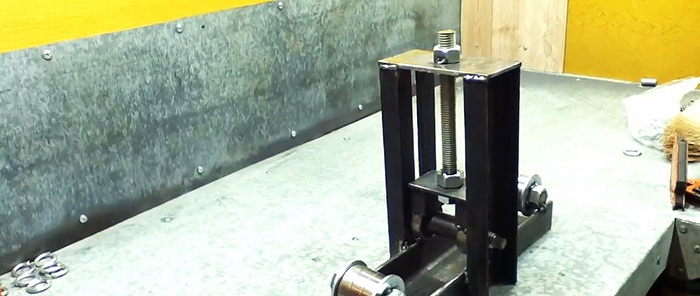

11. We weld the pieces of corners to the channel base, maintaining a gap for the axis of the drive roller (shaft).

12. On one of the already prepared parts of the stud we put a piece of pipe with a diameter of 27 mm and a length of 40 mm. Fill the internal gap with 40mm nails without heads.

13. We weld all the elements around the circumference using electric welding and get a finished shaft.

14. We put bearings on the edges of the shaft.

15. We make a movable carriage by welding two sections of a 20x40x30 mm profile pipe, a rectangular steel plate 80x50 mm and a shaft with bearings into a single structure.

16. At the intersection of the diagonals, mark the center with a core and drill a hole with a diameter of 18 mm for the pin in the upper part of the carriage using a drill and reamer.

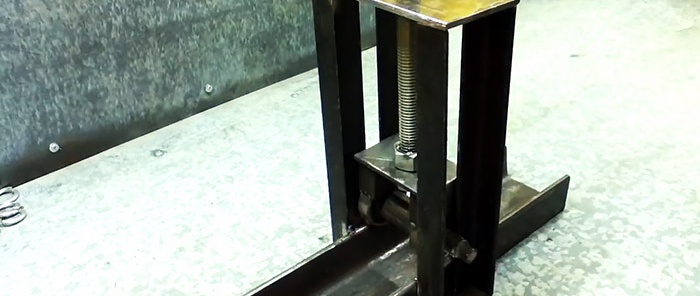

17. We assemble the lifting mechanism, consisting of a pin and three M18 nuts, two of which are spot welded to the pin threaded into the hole of the carriage platform.

18. Cut out a rectangle of approximately 70x130 mm from a steel sheet 5 mm thick, which will be used as a stop for the lifting mechanism. Mark the middle and drill an 18 mm hole similar to the base of the carriage.

19. We assemble the manufactured elements into a single structure. To do this, install the carriage with the drive shaft in the guides.

20. We put it on the stud and install the support plate.

21. Screw the nut onto the stud until it stops and spot-tighten the joints using electric welding.

22. We weld the previously made rollers along the edges of the channel base.

23. We weld a 25-30 cm handle from a 20x20 mm profile pipe to the lifting and clamping mechanism.

24.We make a mechanical drive lever from a 20-25 cm section of a 20x20 mm profile pipe and weld it to the drive roller (pin). The drive handle can be borrowed from any old power tool by first drilling a hole for it. If this is not available, you can instead weld a 12-14 cm piece of round pipe to the lever.

25. The pipe bender is ready, let’s carry out the test.

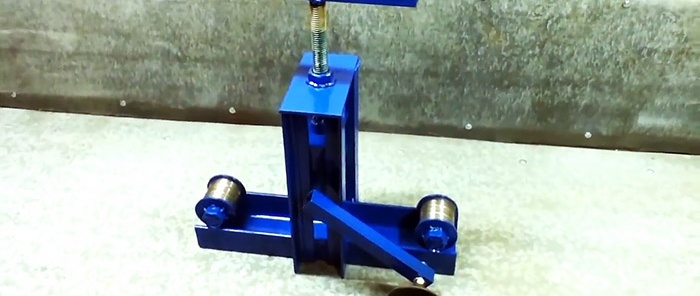

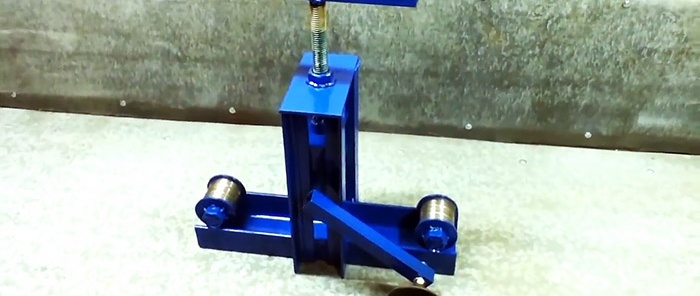

26. And finally, the final stage is painting our pipe bender. How can such a hand-assembled technical masterpiece not be given a respectable appearance?

However, this is a purely individual question and we will not dwell on it in detail. We only note that you first need to remove all roughness with a file or grinder, degrease it well with a solvent, and cover it with primer. But in any case, although it pleases the soul, it does not affect the result in any way.