Materials:

- mirror or glass;

- sandpaper P800 and P3000;

- container with water;

- dry rags.

Knife sharpening process

To sharpen, you need to remove both knives from the machine. They are usually held in place with just two screws. When disassembling, it is important to act carefully, since many machines have a spring between the knives, which is not always secured, so it can fall out.

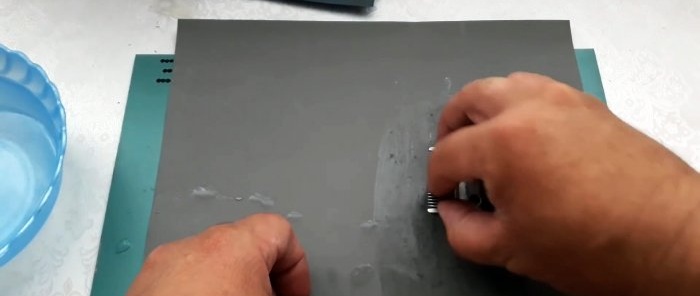

Knives are sharpened only on one flat side. It is necessary to remove the potholes, scratches, and possibly traces of corrosion that have appeared on it. To do this, the knife is wetted in water and the flat side is applied to P800 sandpaper placed on glass or a mirror. This lining gives a perfectly flat surface.Then you need to press your fingers into the center of the knife and move it along the sandpaper in a back-and-forth motion, trying not to shift the pressure to the side. Shifting the pressure point will cause the edges to wear off, but you need to remove the entire plane evenly.

Periodically, the knife should be washed in water to remove small grains of metal and abrasive from the paper. This will allow you to evaluate the plane. On P800 paper, rough scratches must be completely removed.

After sharpening with a coarse abrasive, the surface of the knife becomes matte. Next, you need to rinse it under running water to completely wash away the smallest adhering grains of sand.

Then the knife is wetted again in a container with fresh, clean water and polished using P3000 sandpaper placed on a mirror or glass. This abrasive will bring the surface of the knife to absolute gloss. He will become like a mirror.

After sharpening to a mirror, the knives need to be treated with oil. It is applied drop by drop onto the rubbing surfaces. Then the knives are installed back on the machine. It is important to do this the same way they stood before. What matters is the protrusion of the lower knife beyond the edge of the upper one. The fact is that the clamping screws have play, which makes it possible to move the knives relative to each other a few millimeters to the side. Before disassembling the sharpening machine, it is important to look at how they stood, or better yet, take a photo, and then install them back in the same way.