When performing welding work, it may be necessary to fill a fairly wide seam. For a non-professional welder, this is an almost impossible task. In fact, everything is not so difficult if you use one trick.

What you will need:

- a pair of electrodes;

- hammer;

- sandpaper;

- grinder with a cleaning disc.

Process of filling large seams

To prevent the molten electrode from flowing down when applying a plane, and to prevent the parts being connected from being burned, it is necessary to use an additional rod. It is easiest to work with a cleaned electrode core of the same cross-section as the one used for welding. You need to tap it with a hammer and wipe off the remaining coating with sandpaper.

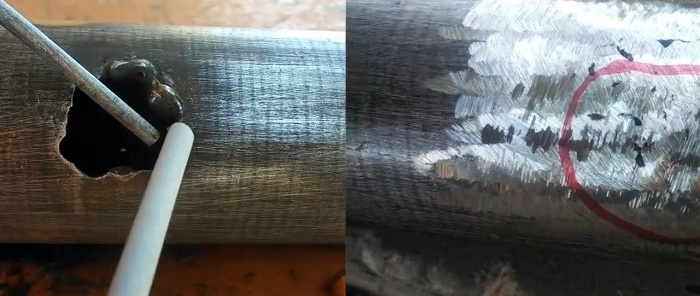

When welding a hole, it is necessary to apply the end of the cleaned core to its edge, creating a gap of a couple of millimeters. The seam is placed between the rod and the wall of the hole.

The attached core melts perfectly, while the hot metal from it remains in a given plane. Having reached the edge, you need to hot tear off the attached rod and place it again a little higher. This way the entire hole is filled.In this case, the part itself is not burned. It is quite possible to weld sheet steel or a pipe with a wall cross-section of less than 2 mm. After welding, the seam is sanded with a grinder.

If it is necessary to apply a long wide suture, the same technique is used. First, the end of the core is placed at the beginning of the seam in order to weld the edges together. Then the rod is torn off and placed along the seam at an acute angle. As a result, the large gap between the parts being welded is partially blocked by the core and is divided into 2 narrow gaps. Next, filling is performed with a transverse movement of the electrode.

This welding technique will allow you to weld almost any hole or gap, of course within reasonable limits. At first, before gaining experience, the core will stick to the seam. You should try to displace it while the metal is liquid, and such problems will not arise.