Soldering is a rather painstaking process, all the intricacies of which take months to learn. It's not just the complexity of stripping and tinning, but also a lot of different little things. Let's look at 11 tips that will take your soldering technique to the next level.

Use a stand

Even if your soldering iron can be placed on a table without its tip touching the tabletop, still use a stand. There is a risk that you will accidentally pull on the cable and simply burn through its insulation. With a stand this is eliminated.

Do not clean the tip with sandpaper

Sandpaper cleans the sting very well, but it ruins it. Use a special wire sponge. Just wipe it on each side and it will be clean. Don't scrub too hard with this brush.

A sponge soaked in water also cleans the tip well. She can't hurt him at all, so this is the best alternative.

If you don’t have anything at hand, you can simply shake the soldering iron downwards and all the solder will fall onto the table. The method is less effective, but it works.

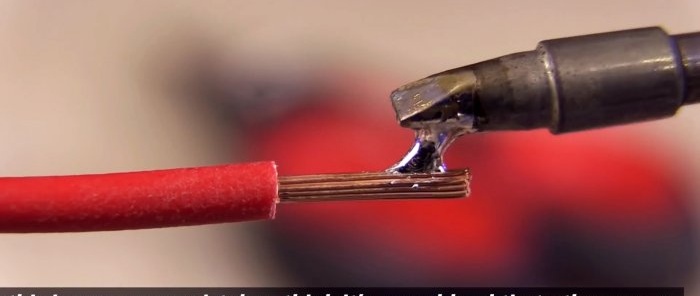

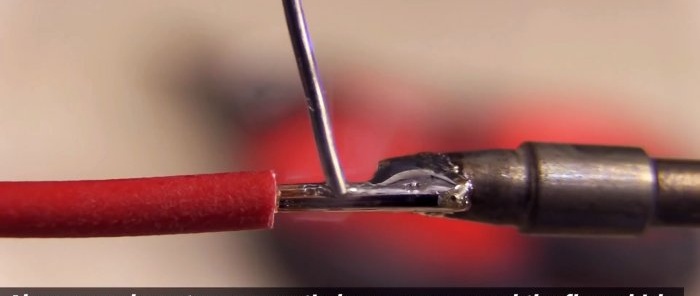

Do not tin the wire with solder from the tip

When transferring solder from the tip to the wire, nothing normal will happen.We need to act differently. Heat the wire with a soldering iron and apply tin to it, then it will spread perfectly.

When heating the wire, there should be solder on the tip

If you simply apply the tip to the core, then due to the small contact area it will take a long time to heat up. Just apply a little solder to the soldering iron itself first, and then it will serve as a heat conductor. As a result, the wire will heat up faster.

First we tinker, then we solder

To solder 2 wires, or a core with a connector, you must first tin it. Then a little tin is applied to the tip, the tip is leaned against the connector, it heats up and then the whole thing is filled with molten solder.

The situation is similar when soldering wires to a contact. You need to tin both surfaces by heating them. Then they are applied to each other, heated and soldered themselves without additional tin.

Never cool the tip in water

If the tip is too hot and you need to reduce its temperature, you should not put it in cold water. Ideally, let it cool naturally. To speed up the process, you can turn off the soldering iron and wipe it with a rough cloth. It will take on some of the heat.

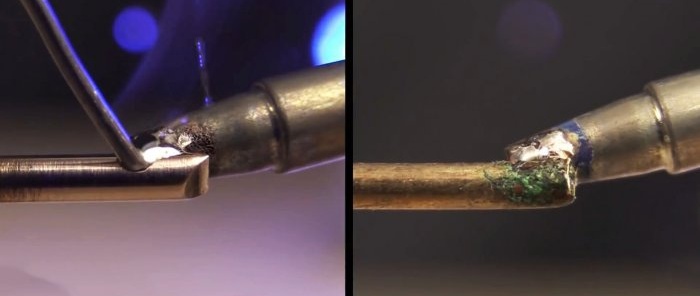

Soldering with oxide film is useless

Do not attempt to solder parts if there is an oxide film on their surface. It will simply prevent the tin from sticking. It must first be wiped off with an abrasive.

Not only a noticeable green oxide film, but also a recently appeared dark one can interfere with soldering. Ideally, always first wipe the surface with an abrasive, and only then solder, especially if it is a board.

Don't breathe fumes from solder and flux

Practice soldering in the fresh air or under a hood. At the very least, put a fan on so it blows the smoke away from your face so you don't breathe in the concentrate.It is harmful to health, so do not solder anything in a closed, unventilated area.

Every job must have its sting

There is no need to try to solder a small part with a large tip and vice versa. In the first case, it will be inconvenient, and you will definitely melt something along the way or solder excess. In the second case, high-quality soldering will not work, since the parts will not heat up evenly.

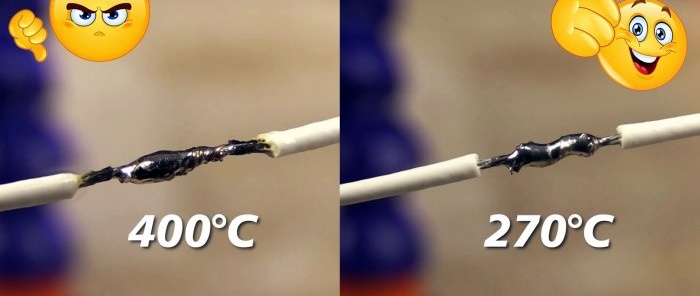

Control the temperature

If you use a soldering iron with regulation and a thermometer, be sure to control the temperature. It should be the same as needed for a specific solder. An overheated tip, in addition to tin, will simultaneously melt various dielectric elements, such as insulation, inserts, bushings.

The thickness of the solder must correspond to the size of the parts being soldered

If you need to solder a small part, do not use a thick rod of solder for this and vice versa. Its diameter must correspond to the scale of work.

Also check out this life hack on how to instantly clean a sting - https://enn.washerhouse.com/4480-kak-momentalno-ochistit-zhalo-payalnika.html