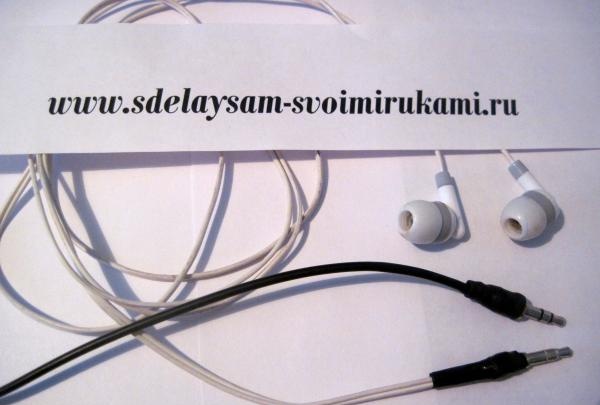

Let's try to repair this problem ourselves. To do this we need glue, a regular spool of thread, a piece of heat shrink tubing and electrical tape.

It is advisable to use glue that is designed for gluing fabric. But I only had Monolith in stock. Under no circumstances should electrically conductive glue be used. Tools you will need are a soldering iron with a thin tip, flux, solder, wire cutters, a sharp knife, a lighter and a tester.

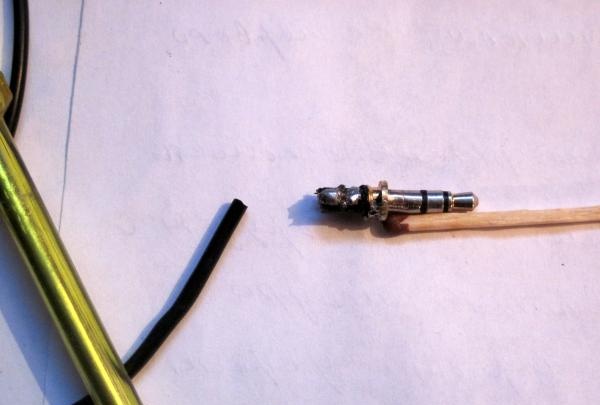

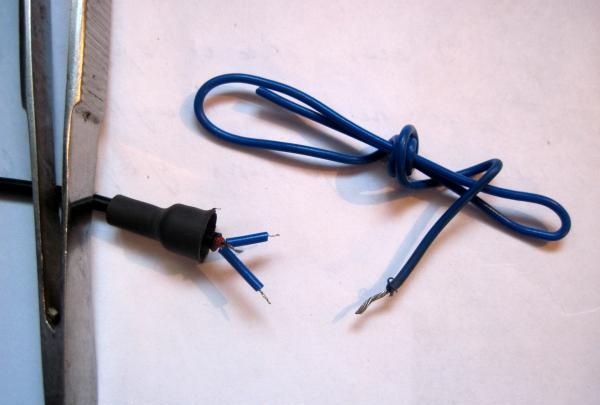

First, cut off the wire from the plug and use wire cutters to remove the protective casing from it.

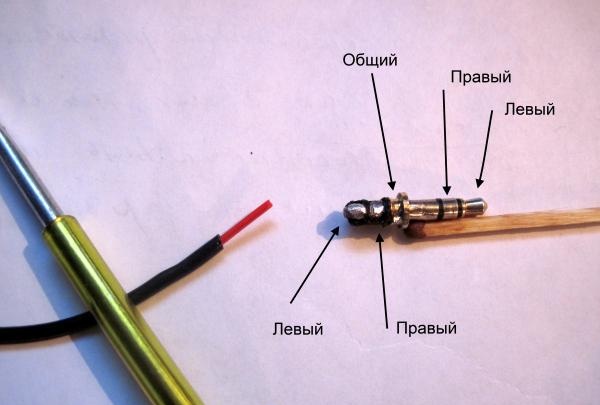

Using a soldering iron, carefully remove the remaining solder and check the plug for a short circuit. Our plug has three contacts. It's common, left and right

channel.

The tester, when testing these contacts with each other, should show infinite resistance. If this is not the case, it means either the tin is “hanging snot” or the insulator is melted. You can try to remove the “snot” with a soldering iron or a needle file. In the second case, the plug is most likely beyond repair. We'll have to look for another one. But in our case everything is fine and we continue to work.

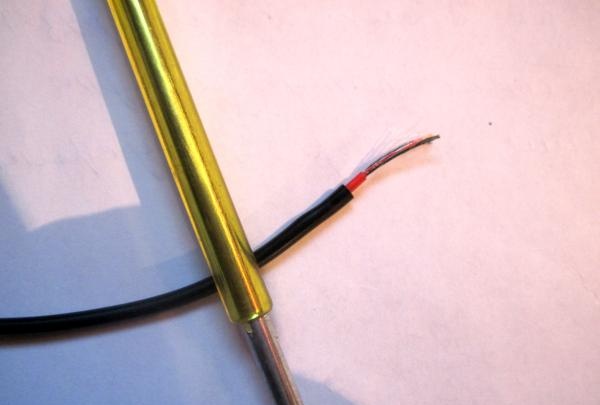

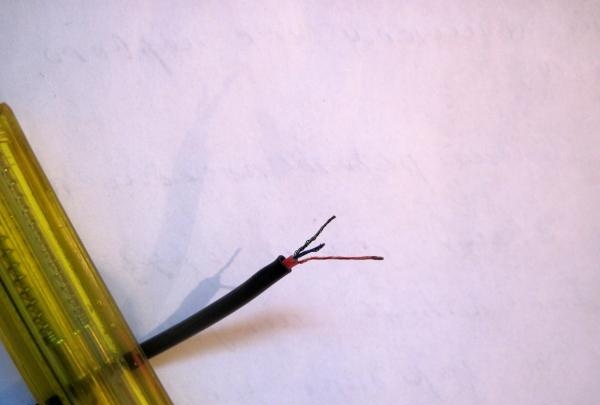

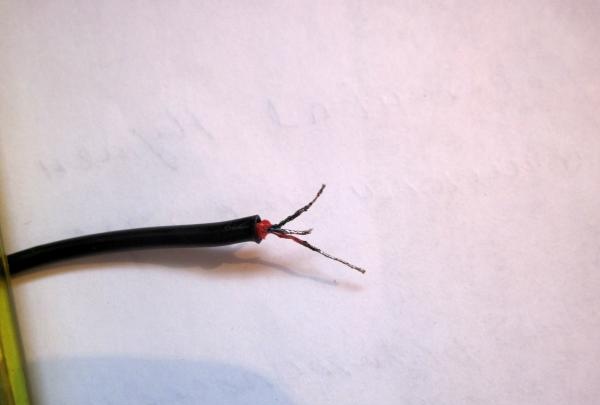

Carefully remove the insulation from the wire.

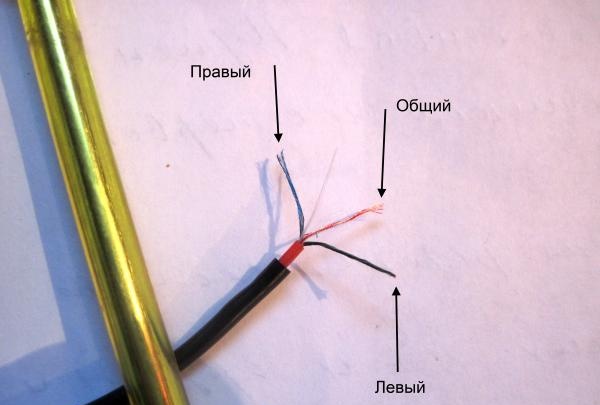

Three multi-colored wires go from it to the plug.Blue, green and gold (braid). Golden is the common wire. The other two are the left and right headphone channels.

You have to work carefully. Each strand of the wire is very thin and fragile. Also, the wires are in silk insulation. The ends of the wires must be tinned (coated with tin). To do this, we clean the wires from the silk insulation with a sharp knife and twist them together. You can try to burn the insulation a little with a lighter flame and clean it until it shines.

After tinning, we measure the resistance of the left and right channels relative to the common wire. In our case it was about 50 ohms.

Now comes the most labor-intensive process. This is soldering wires to a plug.

Before soldering, do not forget to put a heat shrink tube on the wire.

It is advisable to secure the plug somehow. For example, in a vice or using any other clamp. I used POS-61 as solder, and an alcohol solution of rosin as flux. Before soldering, you need to put small cambrics on the wires, made from the insulation of any thin wire.

We solder quickly and carefully so as not to burn the wire or melt the insulators. If a drop of solder does not lie down neatly, you can correct it with a file. After soldering, we make a control measurement of the resistance. If it matches what happened before, then the job is done successfully. Otherwise you will have to do the work again. Next, drop a little glue onto the soldering area, not letting it get on the plug contacts, and let it dry.

After this, we wrap the soldering area with a little effort with thread and tie it in a knot. We make a control measurement of resistance. Then we soak the wrapped thread with glue and let it dry well.

Check the resistance again.

And the final touch is to install the heat shrink tube in place. It is advisable to heat the tube with a soldering hair dryer.If it is not there, you can try it with a lighter flame.

We do this quickly so as not to damage the wire and soldering. If you don't have heat shrink tubing, you can use electrical tape or tape.

After all these tricky manipulations, we make the last control measurement of the resistance and are happy (or upset) with the result obtained.

I would like to note that the work is very painstaking. It requires minimal skill in working with a soldering iron and may not work the first time.

This method has restored the functionality of many headphones. You can also restore the cords of power supplies and chargers of various gadgets. In the latter case, you need to wire “+” and “-” correctly.