Basic materials:

- shock absorber struts – 2 pcs.;

- plywood 15 mm;

- nuts, extended nut M10;

- long M10 bolt with hex head;

- steel 5 mm;

- self-tapping screws

Machine manufacturing process

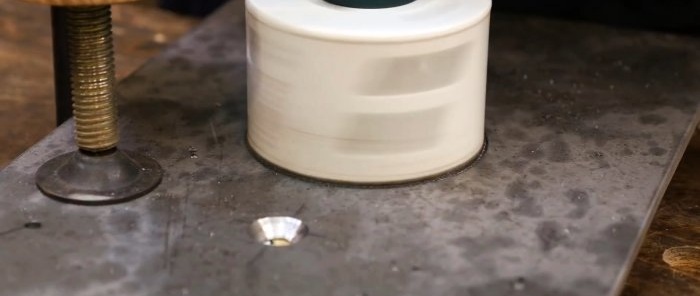

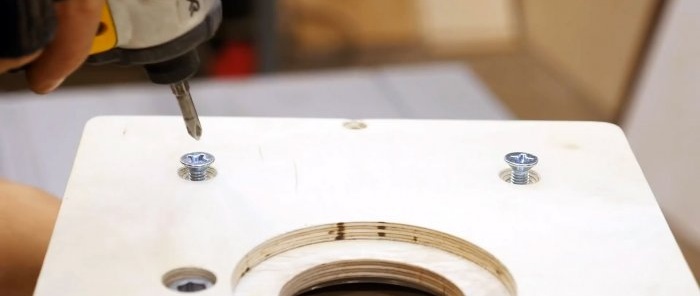

A manual multifunctional milling cutter with a removable base will be used as a drive in a machine of this design. You need to make a table and an adjustment mechanism for it. To do this, you will need to select 2 old, but still working shock absorber struts. The spring support cups and all fastenings are cut from them. The outer bulb is cleaned. The threads on the shock absorber rod are cut off.The ends are aligned and holes are drilled into them. In the latter, an M8 thread is cut for countersunk screws. The flasks are then stained. Next, 6 blanks of 15 mm plywood measuring 26x18 cm are prepared. They need to be marked as in the photo, for a new lifting base for the hand router motor. The shape is drawn as a diamond with circles instead of corners. A hole is marked in the center for the router body. On the sides you need to first draw 2 holes for the shock absorbers, and then 2 more for the wooden racks. 6 blanks are cut out. In 3 of them, a central hole is drilled for the router and one side hole is drilled for the outer diameter of the extended M10 nut. The fourth part is made in a similar way, only the side hole in it is 10 mm. The first 3 blanks need to be glued together. The 2 remaining ones without holes are also glued together. An elongated nut is pressed into the side hole of the part from three layers of plywood. Then the previously laid fourth board with a 10 mm hole is glued on top. After drying, you need to drill the four-layer and two-layer parts for the shock absorbers. Moreover, the double holes are made blind. For a four-layer one, the last layer needs to be drilled only for the rod. Then shock absorbers are pressed into the parts. Next, 2 cuttings are machined, equal in length to the protruding shock absorber casings. They are screwed between the parts with self-tapping screws to increase the rigidity of the structure. The sole for the base is cut from sheet steel. Holes are drilled in it, like on plywood. It is then screwed to the rods with countersunk screws. A long M10 bolt is inserted through the side hole in the sole.It needs to be screwed into an elongated nut pressed into the plywood and locked. Make a pad for the sole from plywood, which will hold the structure on the table. A quarter is selected along its circumference. Holes are also drilled, including for the head of the bolt. The overlay is twisted with the sole. A quarter is selected from the large central hole. This is needed to make the lid. A hole is drilled into the side of the four-layer base piece and a furniture nut is screwed in. You need to screw the wing bolt into it. Then the milling motor is inserted into the base and pressed with this mount. Next, the table is assembled. A window is drilled in it for the overlay on the sole and a quarter is selected. The router with the mechanism is inserted and screwed. Now, by rotating the bolt head on the table, you can adjust the reach of the router tool. After installing the cutter, you need to close the large hole around it with a lid, and the machine is ready for use.Watch the video

How to make a drill stand for a hand drill from a roller chain - https://enn.washerhouse.com/6917-kak-iz-rolikovoj-cepi-sdelat-sverlilnuju-stojku-dlja-ruchnoj-dreli.html