If you install a hand-held circular saw on a carriage that slides along a guide, you will get a very precise, convenient sawing machine. Such equipment is sufficient to cut materials during manufacturing furniture to order, not to mention various little things. You can make a guide from the most common inexpensive materials from a construction store.

Basic materials:

- studs, nuts, washers M10;

- small bearings – 8 pcs.;

- steel strip 15-20 mm;

- profile pipe 30x30 mm;

- corner 30x30 mm;

- plywood 12 mm.

The process of making a guide for a hand-held circular saw

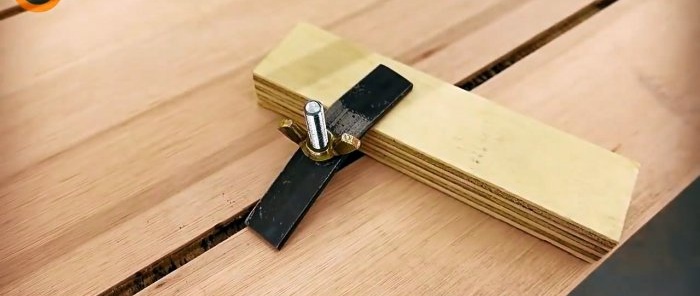

To make a carriage for the guide, you need to assemble the rollers. To do this, 2 bearings are clamped onto a section of the stud, as in the example. You need to collect 4 such sets.

The rollers must be connected in pairs with strip jumpers. The distance between them should be such that it is possible to insert a 30x30 mm profile pipe diagonally.

For the base of the carriage, you need to prepare 2 pieces of corner 30x30 mm, 30 cm each, and a couple of plywood boards of the same length, 10 cm wide.A corner, plywood and a pair of rollers are twisted together into half a carriage. You need 2 of these parts.

2 pieces of 53x13 cm are cut out of plywood. Triangular seats for guide profile pipes are cut out on them. The distance between the cutouts should be such that it is possible to screw the circular onto the installed halves of the carriage.

Also, the base of the machine 100x53 cm is cut out of plywood. Trimmed parts 53x13 cm are leaned against it from the edges, and 2 pipes 103.6 cm long with halves of the carriage are placed on top. The latter are twisted together using corner pieces into a finished frame.

On the base you need to mill 4 T-shaped slots for clamps. 2 threaded steel plates are inserted into each of them. Studs are attached to these mortgages, on which the clamps from the folded strip will be tightened with wing nuts.

Sidewalls with cutouts are screwed onto the edges of the base. For this purpose, corner embeds are used. The guide pipes need to be screwed to the sidewalls.

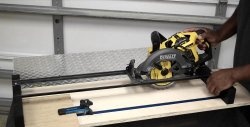

A circular saw is installed on the carriage. Its disk must be positioned strictly parallel to the machine. Then a cut is made on the base, along which it will be possible to align the workpieces when cutting.

A removable cross support is made from a large beam. It will be screwed with studs into the insert plates in the T-slots. A stationery ruler is glued into it to control the length of the cut. The T-track also needs to be milled on the timber itself. This will allow you to install a wooden sliding stop in the form of a corner.

As a result, even a budget hand-held circular saw turns into a precision sawing machine. The costs of its production are minimal, and the real benefits of homemade products are difficult to overestimate.

Watch the video

How to make a convenient table for a router with a simple lift - https://enn.washerhouse.com/5532-udobnyj-stol-dlja-frezera-s-prostym-liftom.html