A factory horizontal bar or crossbar for an apartment may not always fit into the specific conditions of a given room, and the price of this projectile starts from several thousand rubles. This power sports equipment for pull-ups and other strength exercises can be made independently from the remains of rolled metal if you have at least basic plumbing skills.

Will need

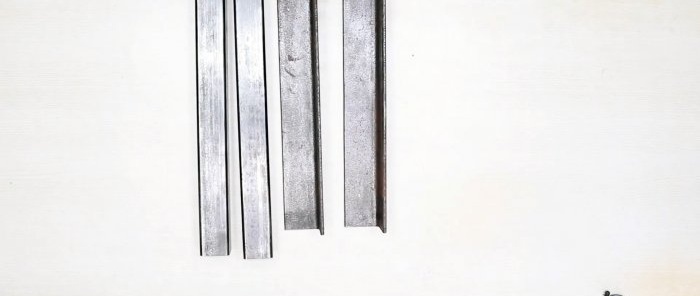

- Profile square pipe;

- steel equal angle;

- steel round pipe;

- drilling machine;

- welding machine;

- magnetic square, etc.

The process of making a home horizontal bar

In profile square pipes of equal length, selected according to strength characteristics, we drill through holes in opposite walls with a core drill on a drilling machine at the calculated distance from the ends.

We insert a steel round pipe of the appropriate diameter and length into the holes of the profile square pipes.

In one of the shelves of two equal length corners, we drill two holes along the axial longitudinal line: one in the center, the other closer to one of the ends of the corner.

Inside the horizontally laid corners, we vertically install profile square pipes flush with the ends of the corners, where there are no holes, and resting on the shelf with holes.

Using a magnetic square holder, we set a right angle and in this position we weld the square pipes to the corners along all contact lines.

To give the joints guaranteed strength and rigidity, we weld reinforcing elements like gussets made from sections of profiled square pipes to the mating corners and pipes at the joints. We beat off the slag formed during welding with a hammer with a narrow chipper and, if necessary, clean the welds.

We insert sections of round pipe into the free ends of the profile square pipes and weld them in several places along the outer contact.

We return the round pipe to its original place, passing the profile square pipes through the holes, and making sure that it extends beyond the brackets at the same distance.

In this position, we weld the round pipe to the profile brackets around the circumference in four transverse planes.

We attach each vertically located corner to a reinforced concrete crossbar or to another capital element of the building’s load-bearing structure, for example to a wall made of a reinforced concrete slab, using special fasteners - anchor bolts.